Tuned mass damper based on anti-buckling restraint support

A technology of tuning mass damping and restraint support, applied in the seismic field of building steel structures, can solve the problems of affecting the damping coefficient, poor shock absorption effect, oil leakage of viscous dampers, etc., to accelerate energy consumption and improve shock absorption energy consumption Efficiency, the effect of increasing internal force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

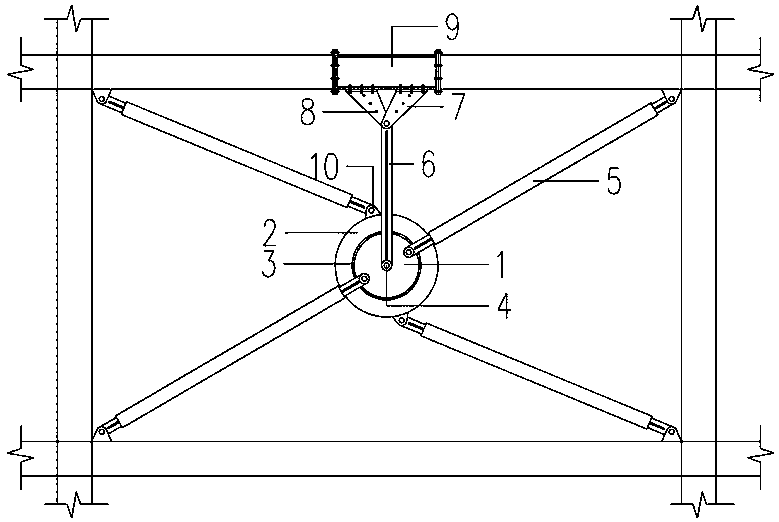

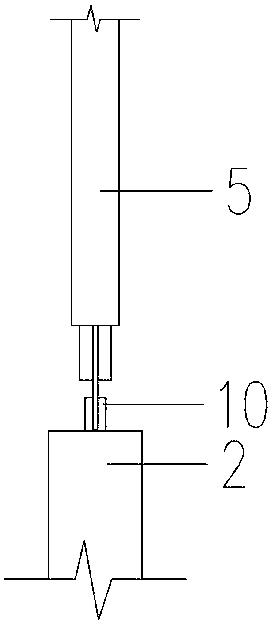

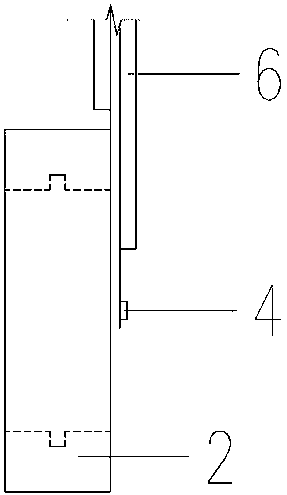

[0022] Embodiment 1: as Figure 1~4 As shown, it is the tuned mass damper based on the anti-buckling restraint support of the present invention. The device mainly includes an inner ring mass block 1, an outer ring mass block 2, a rubber friction layer 3, a pin shaft 4, an anti-buckling restraint support 5, and a cross-shaped mass damper. Connecting rod 6, angle steel connecting plate 7, high-strength bolt 8, energy-dissipating beam section 9, ear plate 10; wherein: the inner ring mass block 1 and the outer ring mass block 2 are connected as a whole through tenon and groove, and the inner ring mass block 1 is glued on the outside There is a rubber friction layer 3, the inner ring quality block 1 is connected with the cross-shaped connecting rod 6 through the pin shaft 4, the upper side of the cross-shaped connecting rod 6 is connected with the angle steel connecting plate 7 through the high-strength bolt 8, and the angle steel connecting plate 7 is connected with the high-streng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com