An inverter capacitor clamping device

A clamping device and capacitor technology, applied in the direction of capacitors, electrical components, etc., can solve the problems that inverter capacitors cannot quickly adjust the clamping tightness of external clamping parts, the external connection of capacitors is not stable enough, and cannot meet the needs of users. , to achieve the effect of stable connection, convenient connection and flexible mobile card connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

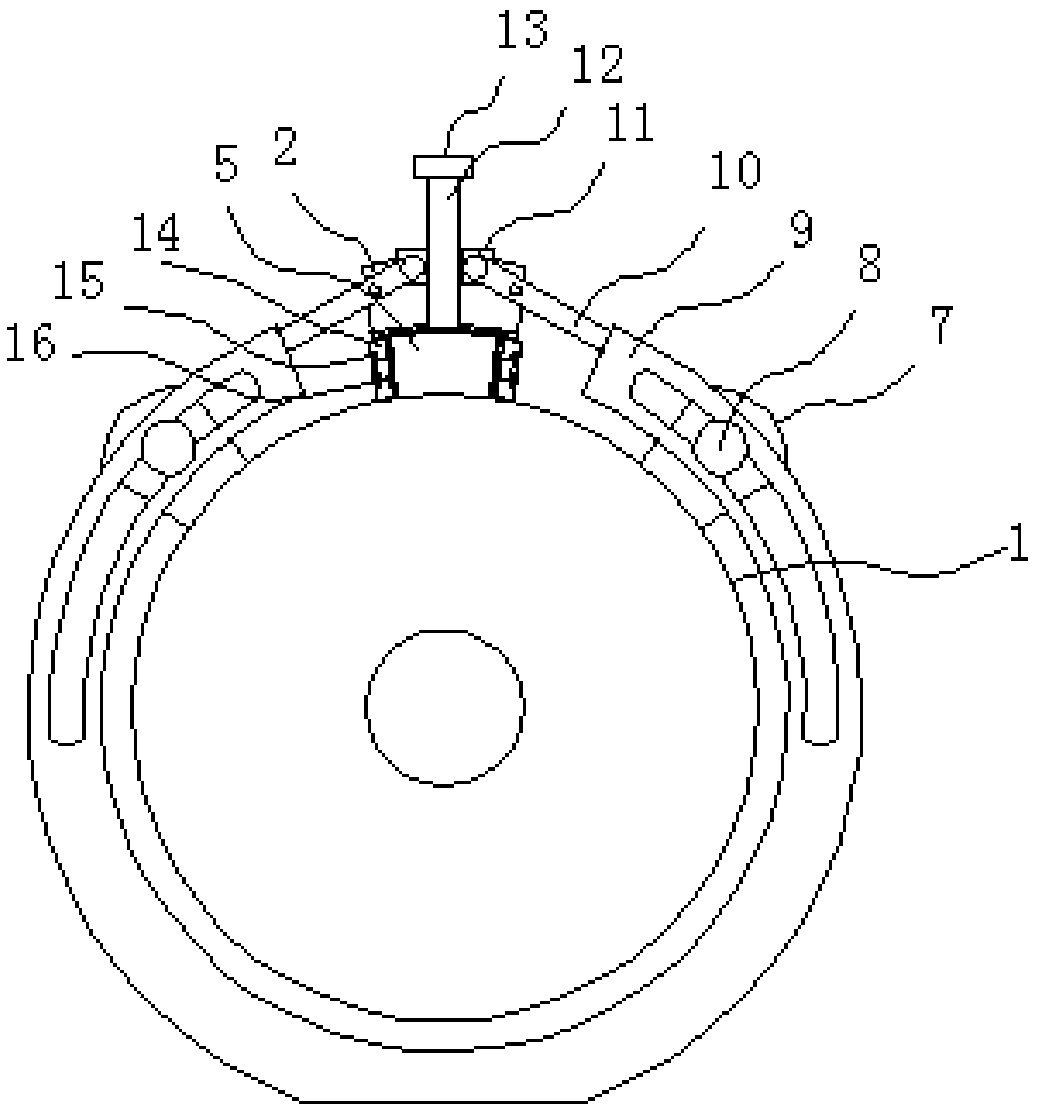

[0016] Example 1: Reference figure 1 , A graded dry inverter capacitor, comprising a body shell 1, a sliding plate 5 is arranged above the body shell 1, a sliding seat 2 is clamped on the sliding plate 5, and two ends of the sliding seat 2 are provided with limit grooves, the sliding seat 2 is provided with a sliding groove that matches with the sliding plate 5, and the upper side of the sliding seat 2 is provided with a rotating groove. The end is provided with a first groove, a connecting rod 10 is rotatably connected in the first groove, a clamping ring 9 is connected to the end of the connecting rod 10 away from the slip ring 11, and a limit seat 7 is symmetrically provided on both sides of the body shell 1. One side of the holding ring 9 is provided with a limiting post 8, one side of the clamping ring 9 is provided with a limiting opening for clamping the limiting post 8, the other end of the threaded rod 12 is connected with a first rotating block 13; the sliding seat 2 ...

Embodiment 2

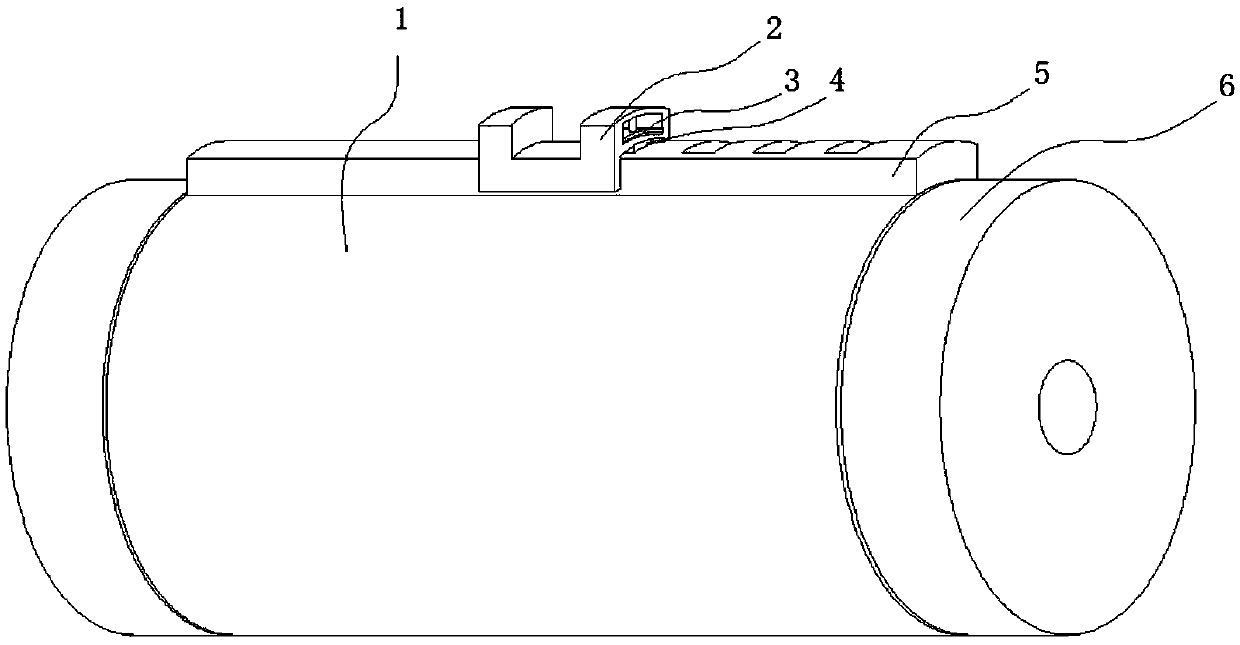

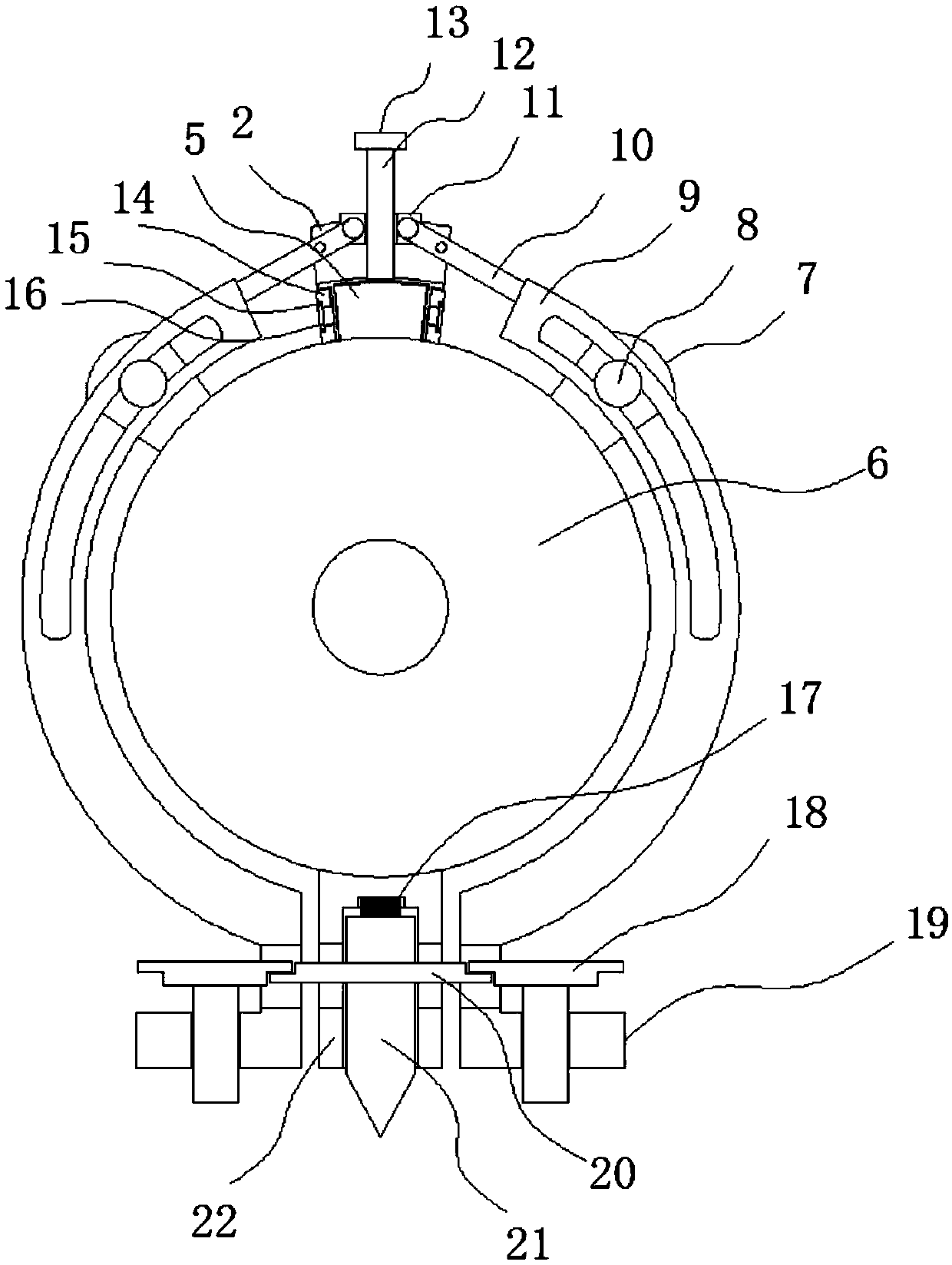

[0017] Example 2: Reference Figure 2-4 , The present invention is applied to a graded dry inverter capacitor, including a body shell 1, a sliding plate 5 is arranged above the body shell 1, a sliding seat 2 is clamped on the sliding plate 5, and both ends of the sliding seat 2 are provided with limit Slot, under the sliding seat 2 is provided with a sliding slot matched with the sliding plate 5, the bottom of the limit slot is provided with a socket communicating with the sliding slot, a plug 4 is inserted in the socket, and a limit plate 3 is arranged in the inner slot in the afternoon , One end of the insert block 4 is connected to the limit plate 3, the upper part of the sliding plate 5 is provided with a slot for clamping one end of the insert block 4, the upper part of the sliding seat 2 is provided with a rotating groove, and the bottom of the rotating groove is rotatably connected with a threaded rod 12. A slip ring 11 is sleeved on the threaded rod 12, the two ends of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com