Gradually-changing dry type inversion capacitor

A capacitor and inverter technology, applied in the direction of capacitors, electrical components, etc., can solve problems such as single connection mode, inability to meet the needs of users, and unstable external connection of capacitors, etc. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

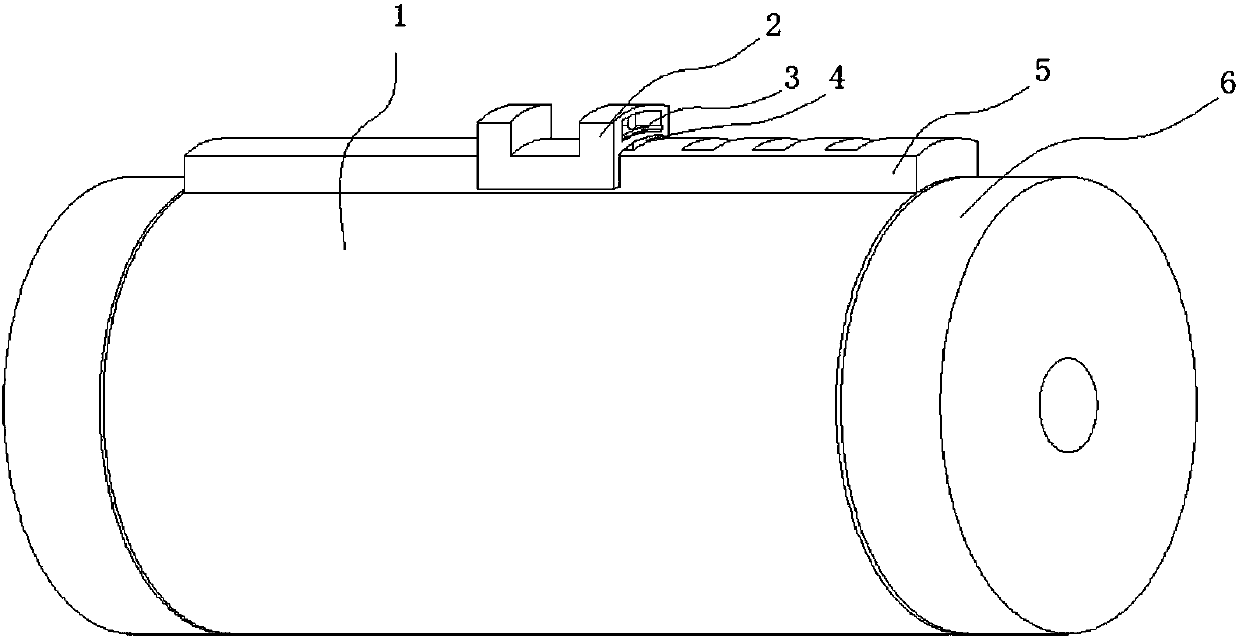

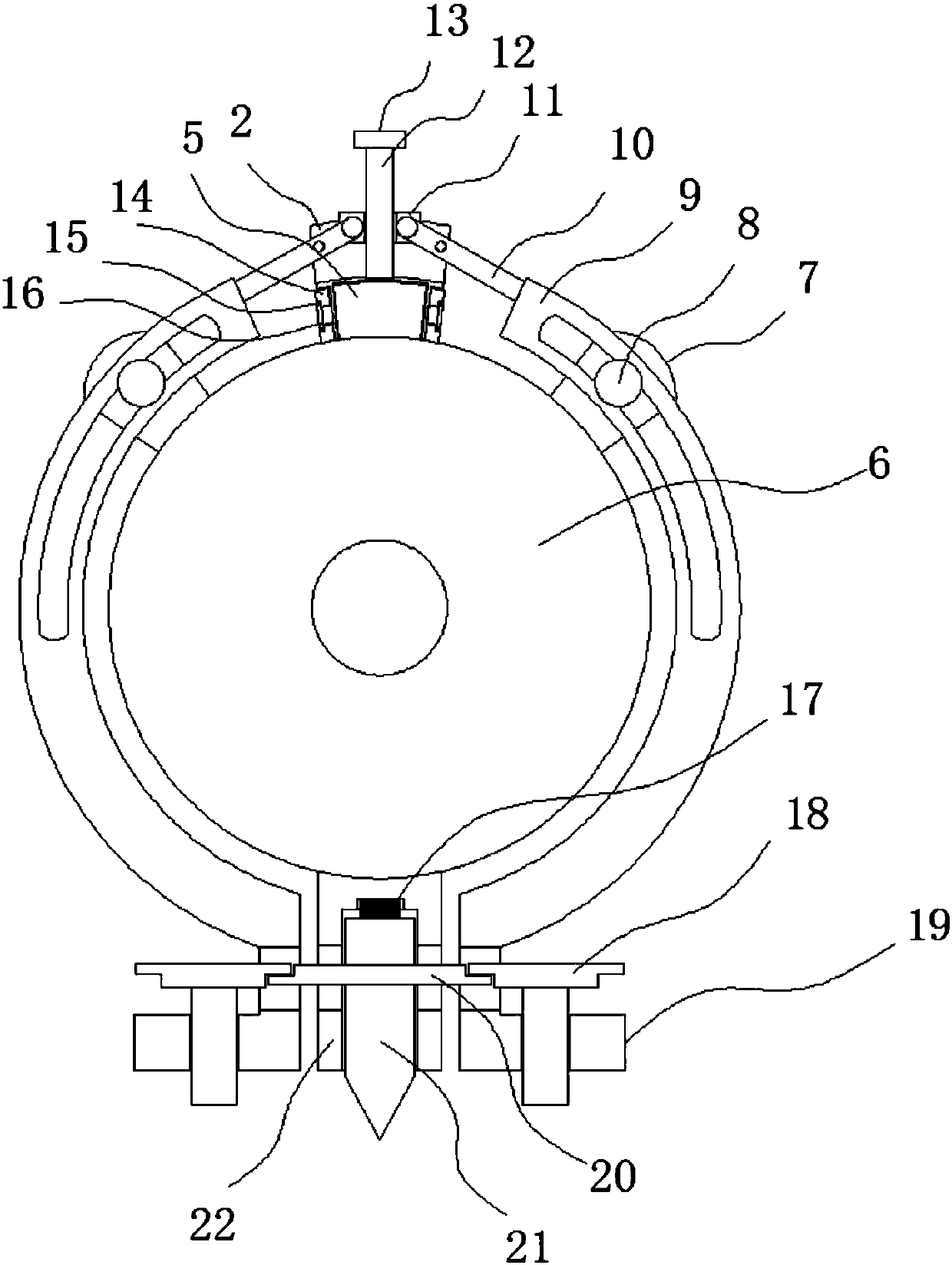

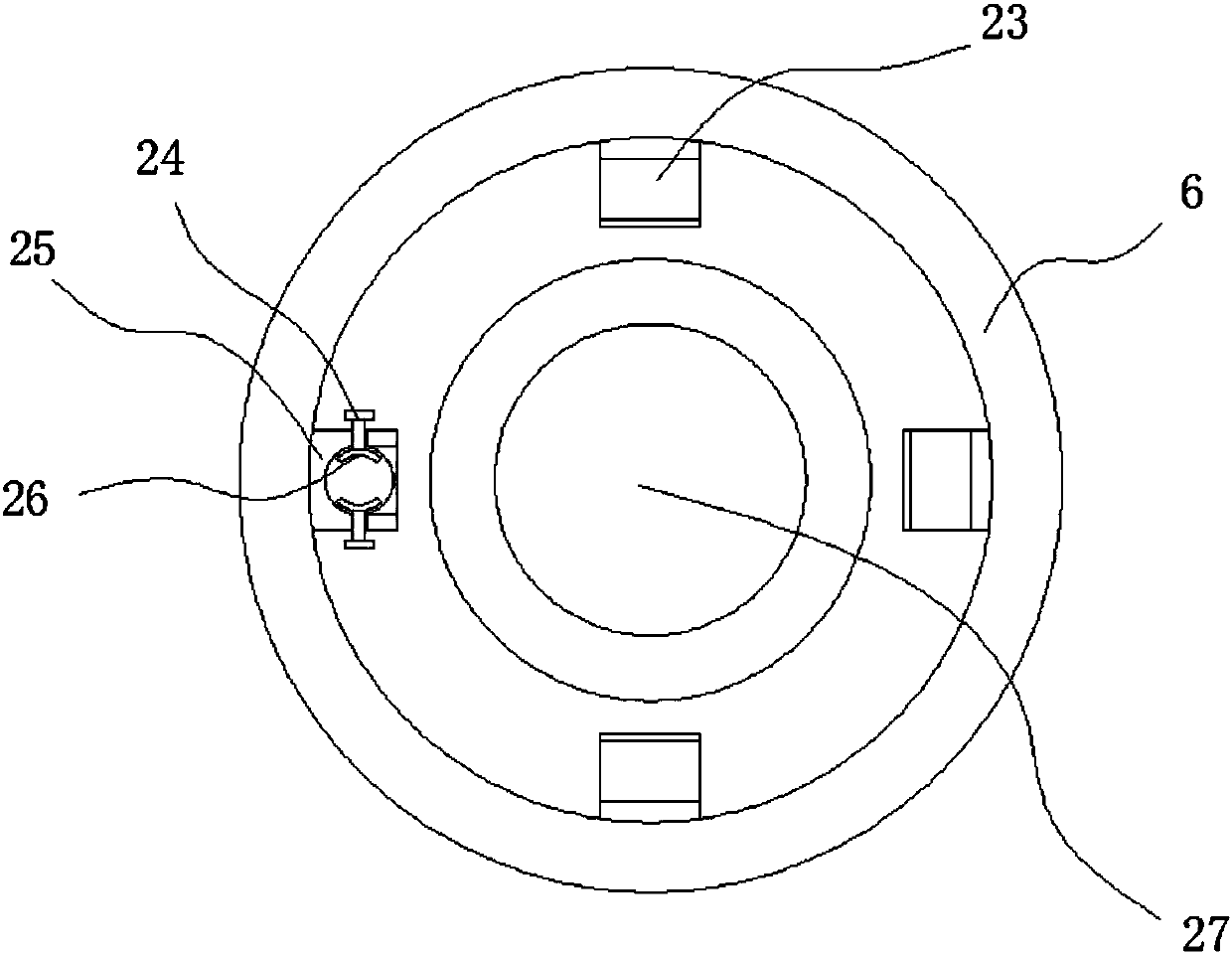

[0022] A gradient dry-type inverter capacitor, comprising a body shell 1, a slide plate 5 is arranged above the body shell 1, a slide seat 2 is clamped on the slide plate 5, and limit grooves are provided at both ends of the slide seat 2, and the slide seat 2 There is a chute that cooperates with the slide plate 5 below the bottom of the chute, and the bottom of the limit groove is provided with a socket connected with the chute, and an insert 4 is inserted in the socket, and a limit plate 3 is provided in the afternoon inner groove, and one end of the insert 4 Connected on the limit plate 3, the top of the slide plate 5 is provided with a draw-in groove for clamping one end of the plug block 4, the top of the slide seat 2 is provided with a rotation groove, and the bottom of the rotation groove is connected with a threaded rod 12 in rotation, and on the threaded rod 12 A slip ring 11 is sleeved, the two ends of the slip ring 11 are provided with a first groove, and a connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com