Transmission mechanism of small potato harvester

A transmission mechanism and harvester technology, which is applied to digging harvesters, harvesters, agricultural machinery and implements, etc., can solve the problems of restricting the development of potato planting industry, high harvest loss rate, and high labor intensity, and achieve simple structure, Low harvest loss rate and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

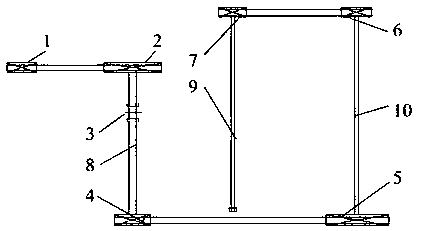

[0009] Such as figure 1 As shown, a transmission mechanism of a small potato harvester includes a drive sprocket 1 and a drive shaft sprocket I2, the drive sprocket 1 is connected to the drive shaft sprocket 2 through a chain, and the drive shaft sprocket 2 passes through the drive shaft 8 Connect with drive shaft sprocket Ⅱ4, drive shaft sprocket Ⅱ4 is connected with lift chain drive shaft sprocket Ⅰ5 through chain, lift chain drive shaft sprocket Ⅰ5 is connected with lift chain drive shaft sprocket Ⅱ6 through lift chain drive shaft 10 Connect, the lifting chain drive shaft sprocket II 6 is connected with the shaking shaft sprocket 7 through a chain, and the shaking shaft sprocket 7 is connected with the shaking shaft 9.

[0010] The drive shaft 8 is provided with a pressure plate jaw clutch 3 .

[0011] The working process is as follows:

[0012] During the working process, the drive sprocket 1 on the gearbox of the tractor is connected with the drive shaft sprocket Ⅰ2 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com