Novel automatic attaching robot

A crimping machine and automatic buckle technology, which is applied to metal processing equipment, feeding devices, positioning devices, etc., can solve the problems of not installing rotating handles and anti-slip sleeves, making it difficult to hide and use pulleys, and not being convenient for fixing metal joints. Achieve the effects of avoiding inconvenient movement, convenient movement and maintenance, and easy fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

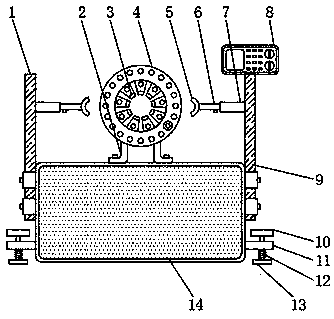

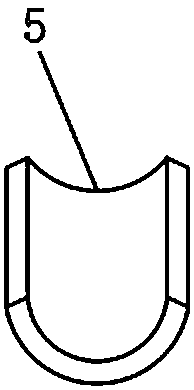

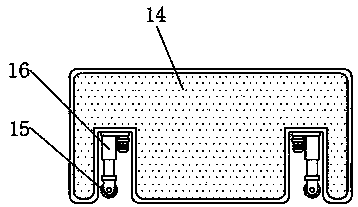

[0023] Example: such as Figure 1-4 As shown, the present invention provides a technical solution, a novel automatic crimping robot, comprising a crimping machine body 14 and a fixed mold 4, one side of the crimping machine body 14 is provided with a second support frame 9, and the other side of the crimping machine body 14 One side is provided with the first support frame 1, and one side of the crimping machine body 14 is provided with a fixed rod 11 near the position below the second support frame 9, and the top of the crimping machine body 14 is provided with a bracket 2, and the inside of the crimping machine body 14 An electro-hydraulic rod 16 is embedded, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com