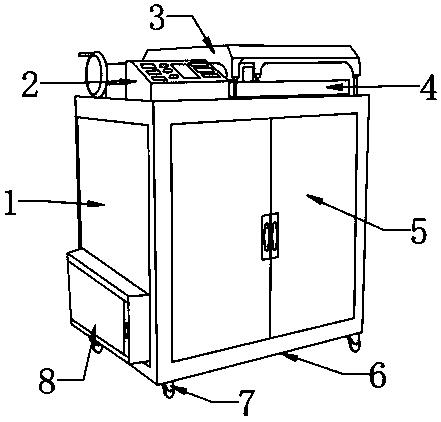

Rebar alternating bending machine with storage function

A technology with repeated bending and storage functions, applied in cleaning methods and utensils, removing smoke and dust, chemical instruments and methods, etc., can solve the problem of inconvenient centralized storage of electrical induction heads, target induction heads, no storage of steel bar repeated bending machines, time-consuming and labor-intensive, etc. problems, to reduce the risk of loss, reduce the trouble of manual removal, and increase the effect of safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

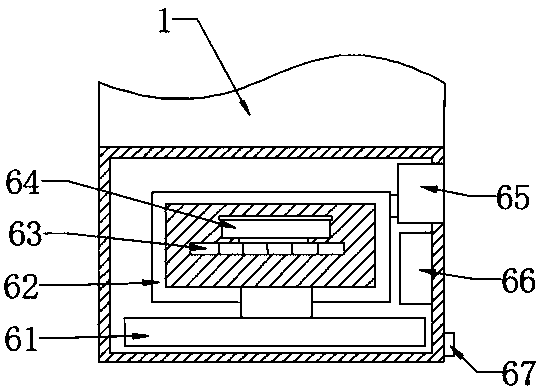

[0025] Specific implementation method: the staff presses the cleaning switch 67, switches the cleaning switch 67 to the on state, the battery 66 transmits the electric energy to the electric motor 64, the electric motor 64 converts the electric energy into mechanical energy, and the electric motor 64 drives the fan 63 to rotate, and the fan 63 The rotation makes the inner cylinder 62 form a momentary vacuum, that is, a pressure difference is formed between the inner cylinder 62 and the outside atmospheric pressure. The repeated bending machine can vacuum and clean the surroundings of the machine body while it is working, so as to achieve the dual-use effect of one machine and improve the functionality of the present invention.

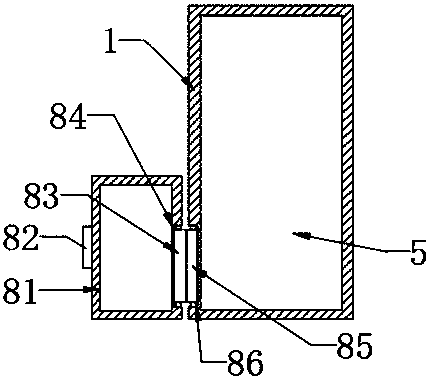

[0026] When the steel bar repeated bending machine is out of use, in order to prevent the loss of the electrical induction head and the target induction head on the steel bar repeated bending machine, centralized storage is required. At this time, throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com