Rail vehicle anti-skid control system and method

A rail vehicle and control system technology, applied in the field of rail vehicle wheel anti-skid, can solve the problems of reducing the electric braking of the bogie and the loss of braking force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

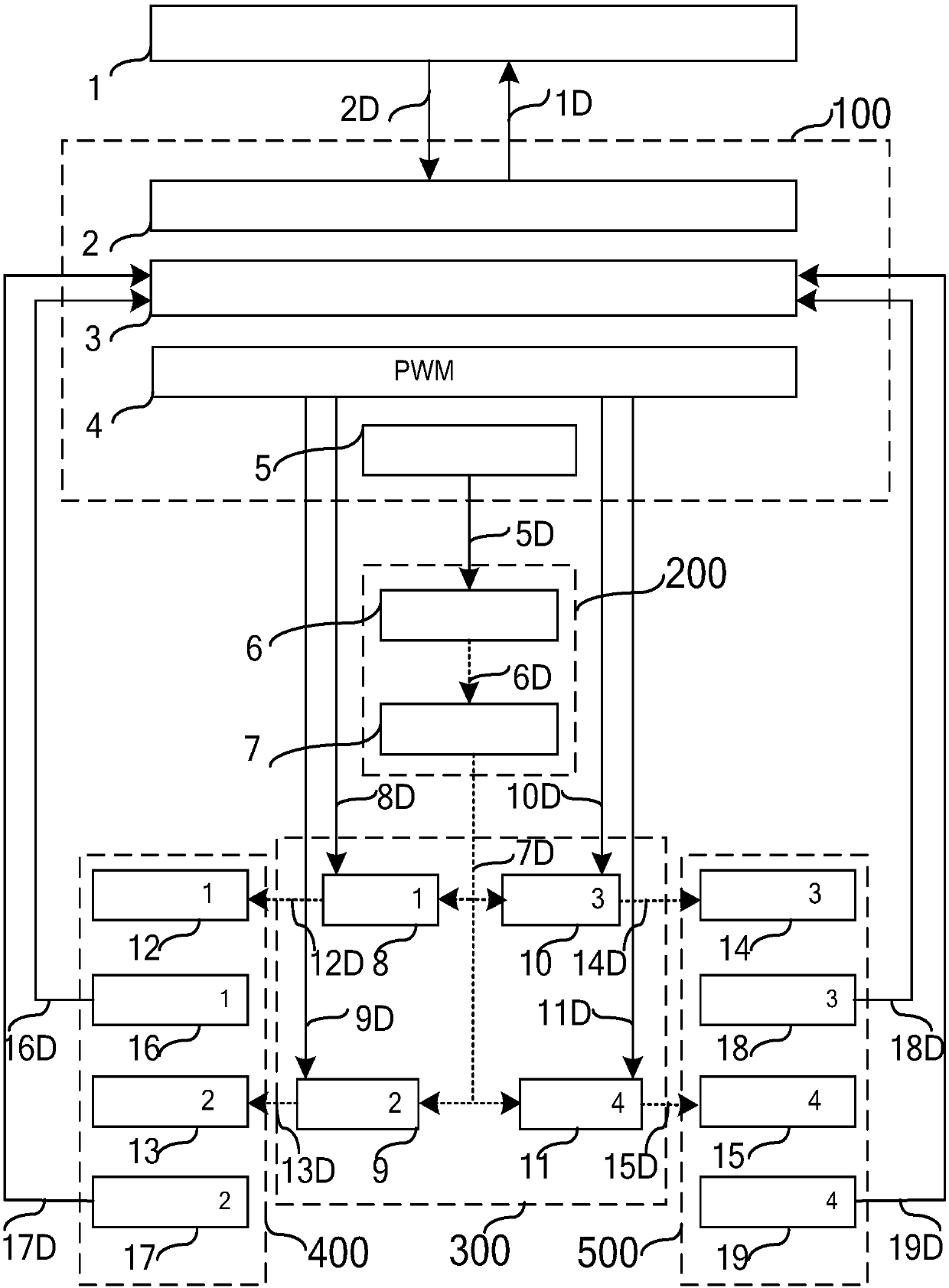

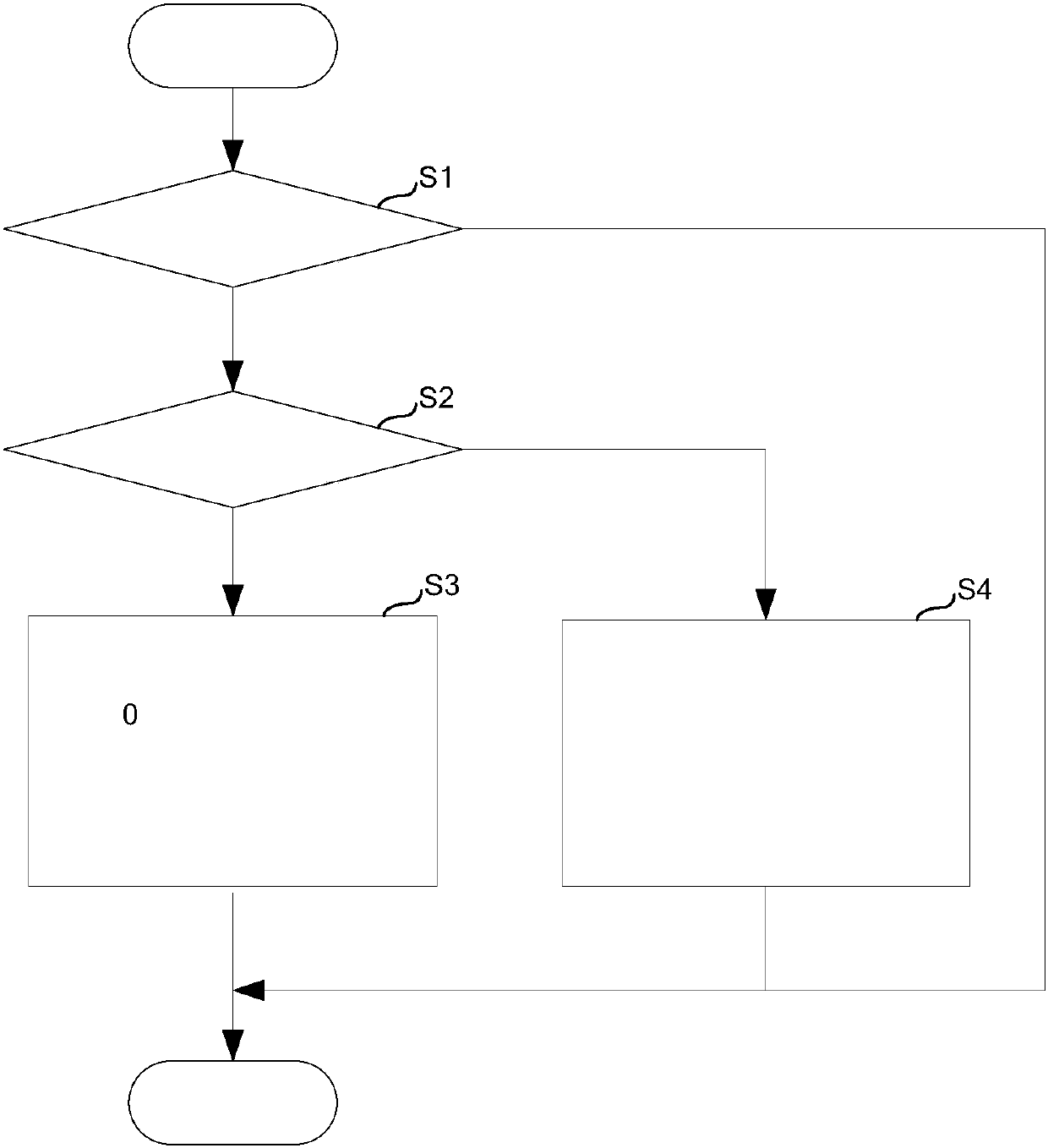

[0032] figure 2An embodiment of a method for antiskid control of a rail vehicle is shown. The electronic brake control unit 100 uniformly calculates the degree of wheel skidding, and reduces skidding by adjusting electric braking and air braking.

[0033] The electronic brake control unit 100 calculates the rotation speed and deceleration of each wheel according to the frequency signals 16D, 17D, 18D, and 19D of each wheel rotation sent by the bogie units 400, 500, and judges the speed of a certain wheel and the maximum speed among the four wheels. When the difference exceeds a certain threshold (such as 10-20km / h) or the deceleration of a certain wheel exceeds a certain threshold (such as 5-15km / h / s), it will be judged that the wheel is sliding (step S1, yes).

[0034] The electronic brake control unit judges that all wheels are not sliding (step S2, yes), and executes electric brake and air coordinated control (step S3): Figure 4 As shown, the electronic brake control un...

Embodiment approach 2

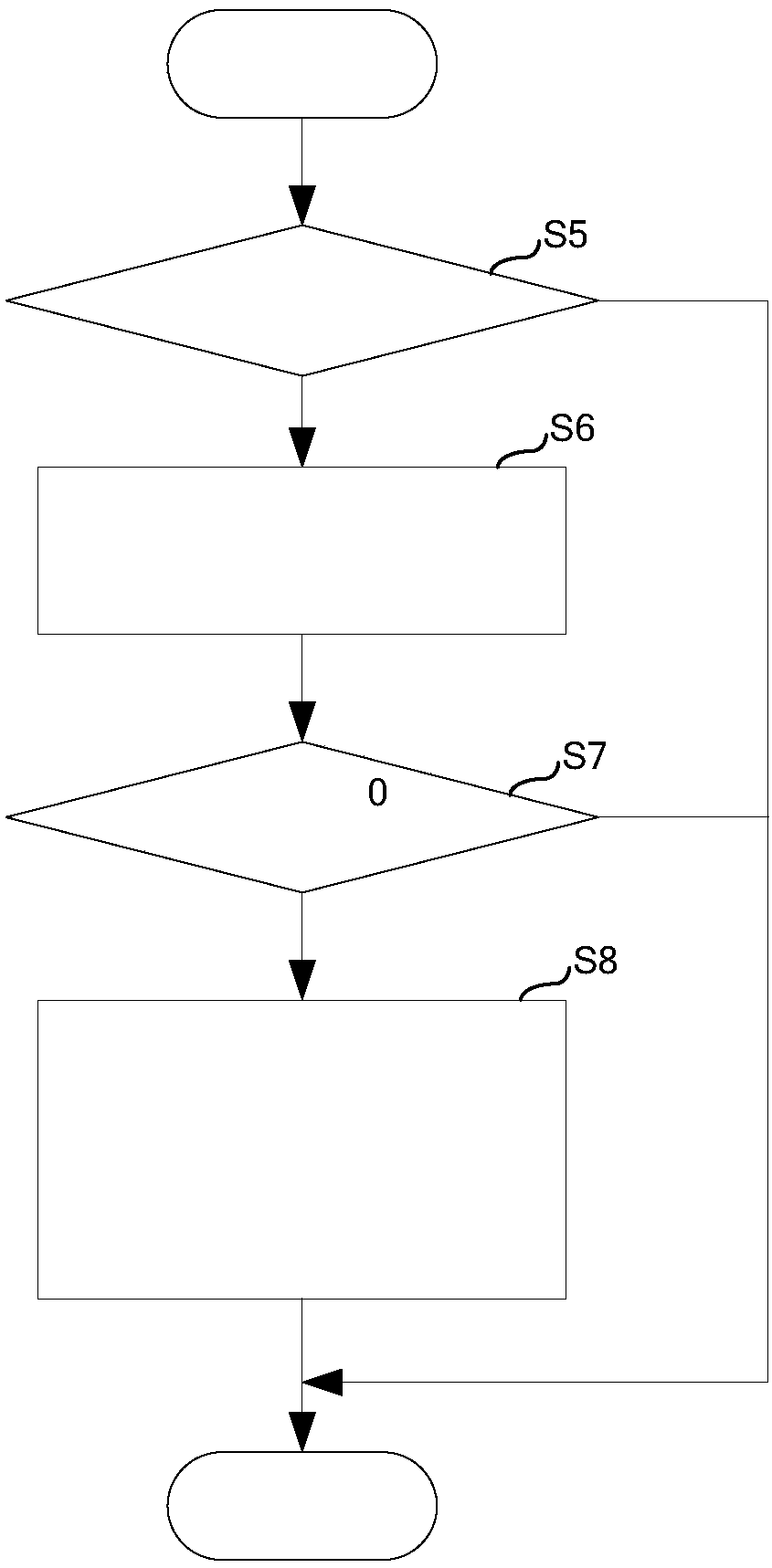

[0039] image 3 It represents another embodiment of the rail vehicle skid control method. The electronic brake control unit 100 uniformly calculates the degree of wheel skidding, and reduces skidding by adjusting electric braking and air braking.

[0040] The electronic brake control unit 100 calculates the rotation speed and deceleration of each wheel according to the frequency signals 16D, 17D, 18D, and 19D of each wheel rotation sent by the bogie units 400, 500, and judges the speed of a certain wheel and the maximum speed among the four wheels. When the difference exceeds a certain threshold or the deceleration of a certain wheel exceeds a certain threshold, it will be judged that the wheel is slipping (step S5, Yes).

[0041] The electronic brake control unit 100 preferentially executes the electric brake control (step S6): if Figure 4 As shown, the electric braking control unit 100 reduces the corresponding electric braking according to the sliding amount, and sends a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com