An air supply system for a hybrid chassis

A hybrid power and air supply system technology, applied in the direction of brakes, brake transmissions, vehicle components, etc., can solve the problems of not meeting the air supply requirements of the hybrid power chassis, and achieve the effects of avoiding impact, preventing corrosion, and avoiding research and development investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

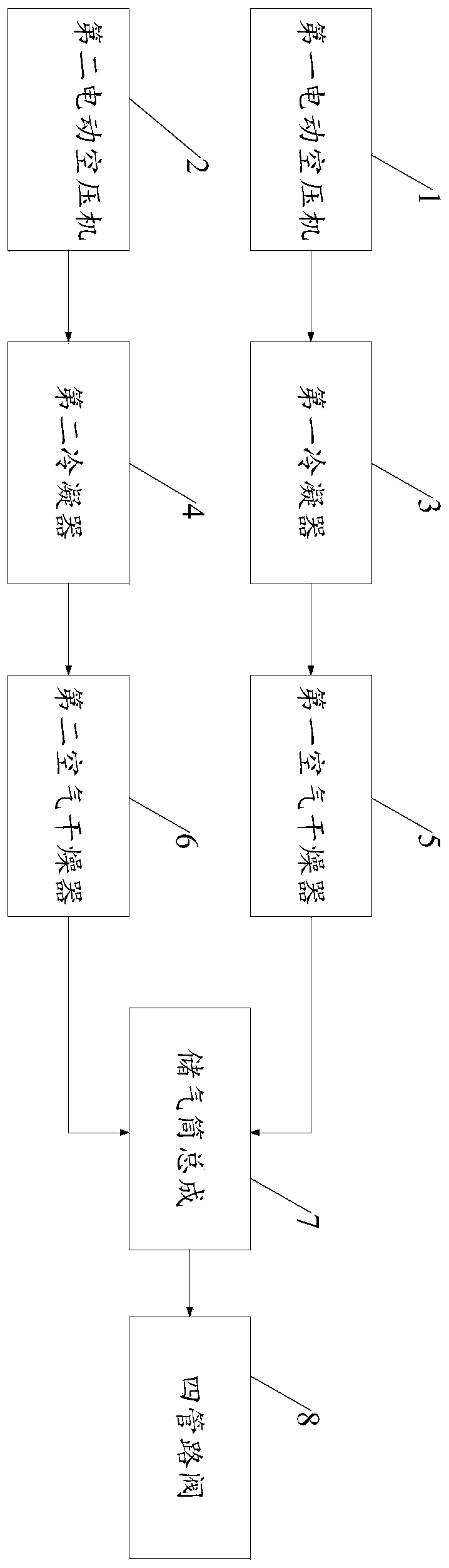

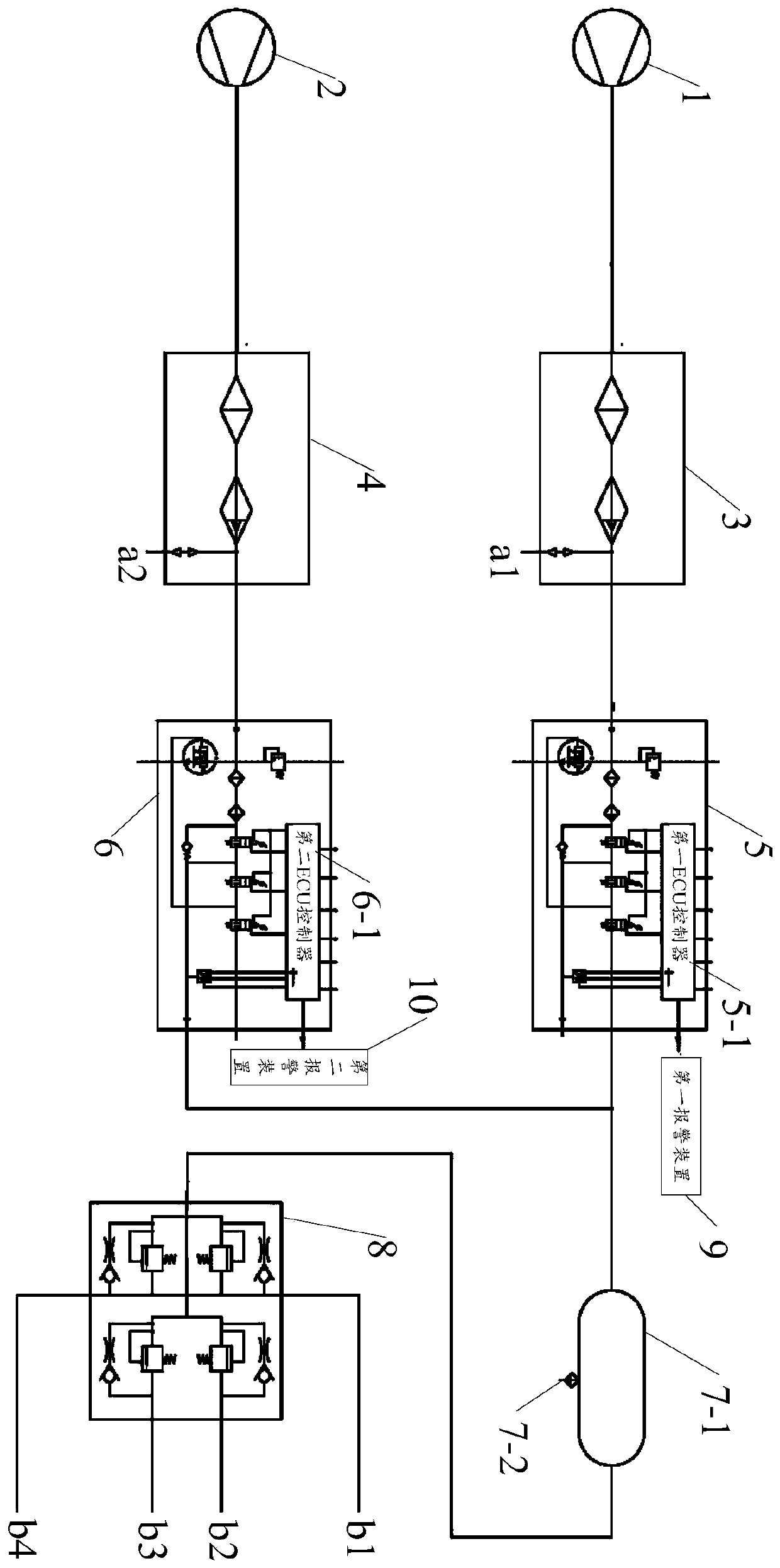

[0027] In view of the technical problem that a single electric air compressor product does not meet the air supply requirements of a hybrid chassis with more than five axes in the prior art, the present invention provides an air supply system for a hybrid chassis, the general idea is as follows:

[0028] The inlet of the first condenser is connected to the compressed gas outlet of the first electric air compressor, and the inlet of the second condenser is connected to the compressed gas outlet of the second electric air compressor; the inlet of the first air dryer The air port is connected to the purified gas outlet of the first condenser, the air inlet of the second air dryer is connected to the purified gas outlet of the second condenser; the dry gas outlet of the first air dryer is connected to the The air inlet and the dry gas outlet of the second air dryer, the air inlet of the four-circuit protection valve is connected to the air outlet of the air storage cylinder assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com