Tank filling device with a vent for a liquid container

A filling device, liquid container technology, applied in the directions of liquid distribution, transportation or transfer device, distribution device, special distribution device, etc., can solve problems such as unreliable assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

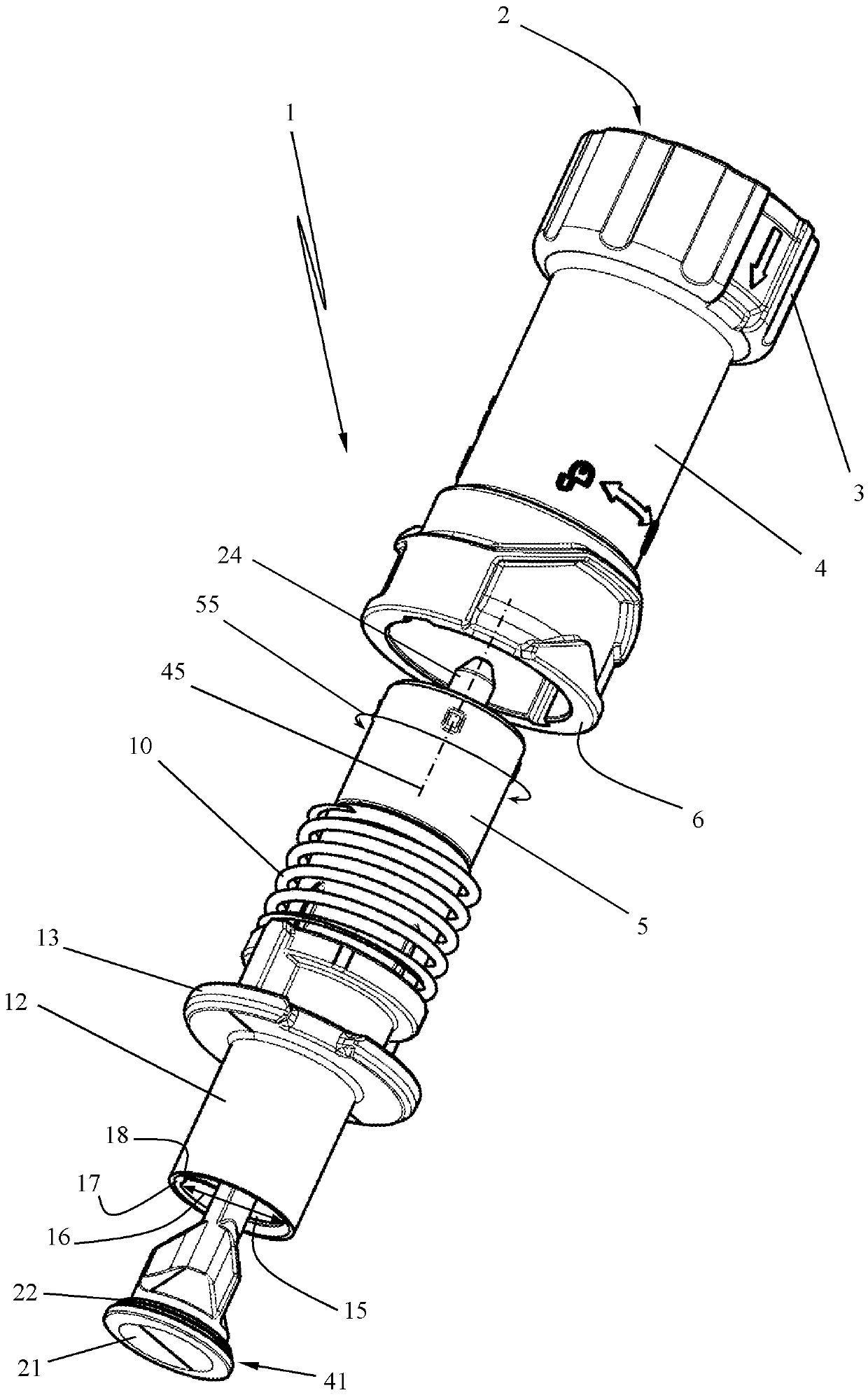

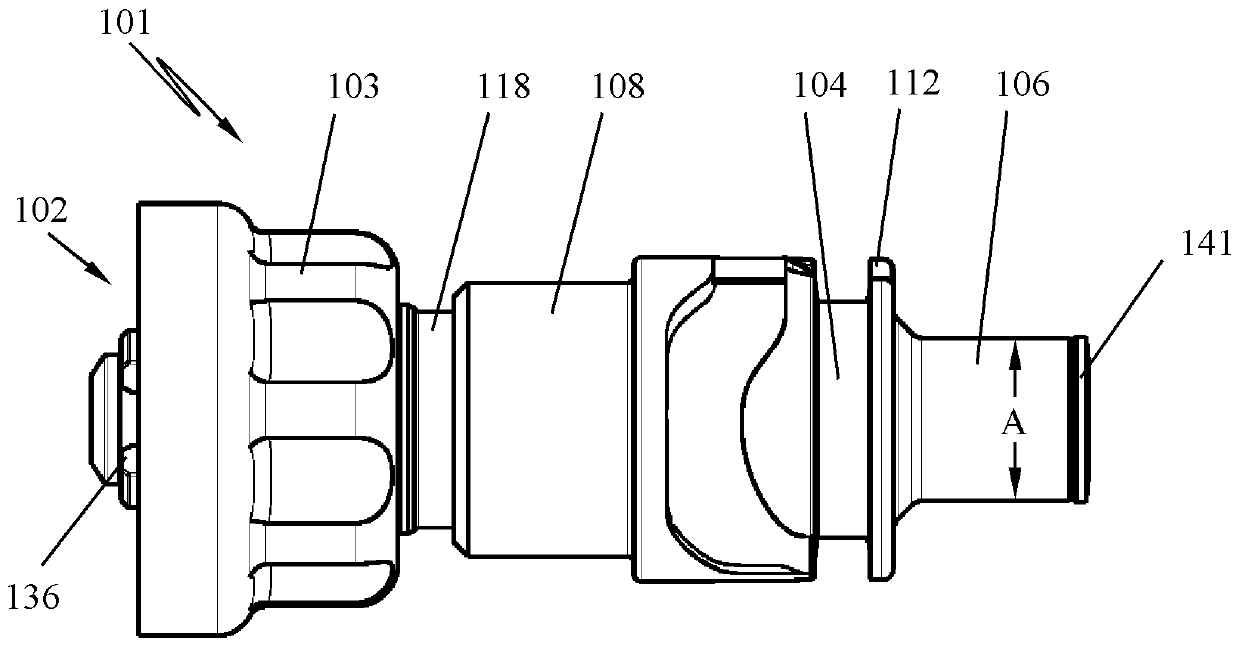

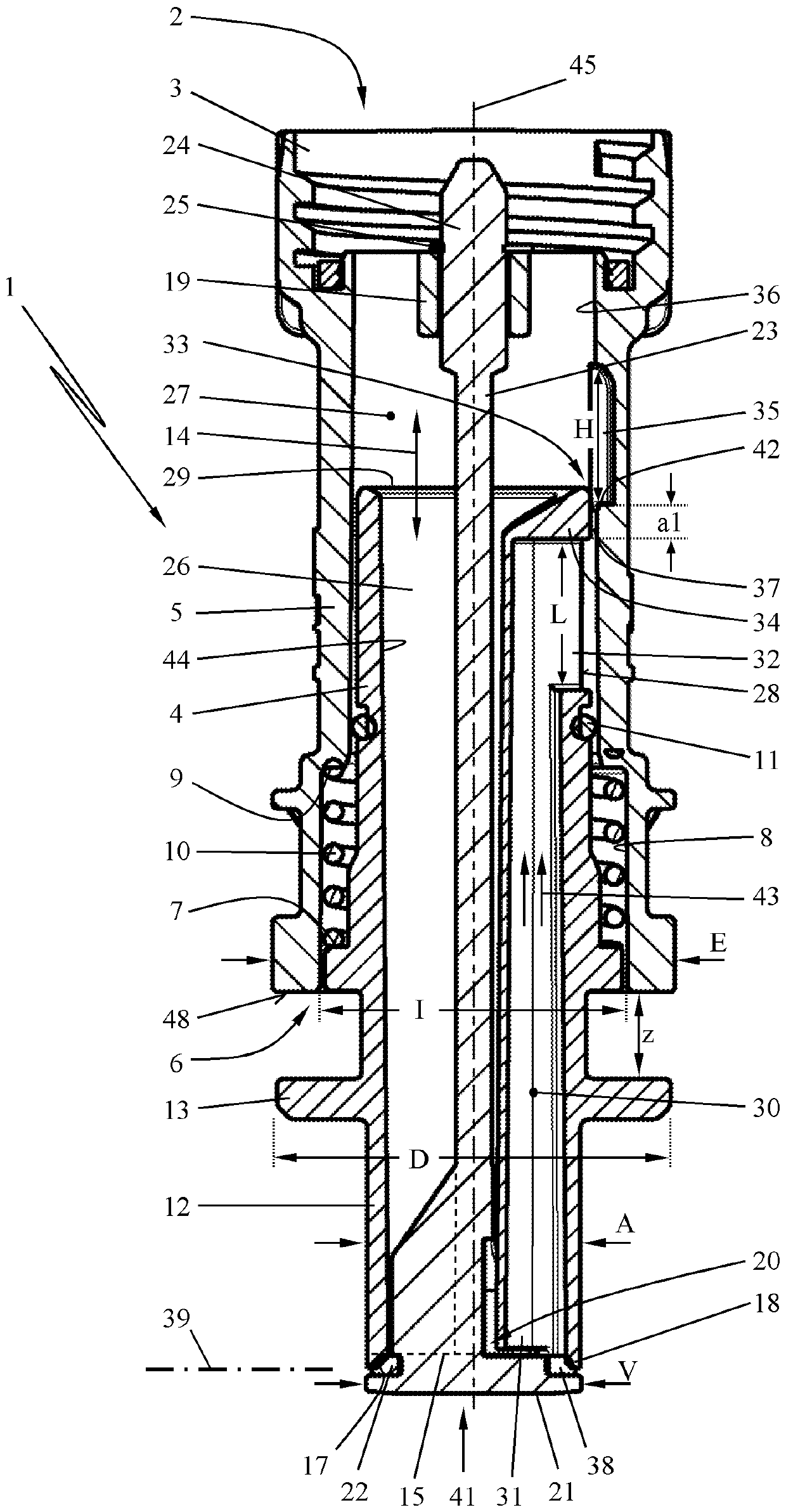

[0027] The storage tank filling device 1 presented in the exemplary embodiment has a mounting end 2 in the form of a screw cap 3 . The cylindrical storage tank filling device 1 is fixed on the liquid container 40 ( image 3 ) place. The liquid container 40 is, for example, a fuel container, which is carried by the user on the spot in order to resupply a working machine operated as an internal combustion engine.

[0028] Such as figure 1 and 2 As shown, the tank filling device 1 essentially consists of a base body 4 with a mounting end 2 . The advantageously cylindrical base body 4 accommodates a suitably cylindrical actuating section 5 which is pushed into an end 6 of the base body 4 lying opposite the mounting end 2 . The actuating section 5 has an annular shoulder 7 which sinks into a widened section 8 of the open end 6 . The widened section 8 has an inner annular shoulder 9 . A spring 10 acts between the annular shoulder 9 of the widened section 8 and the annular shou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com