Clutch with good heat dissipation effect

A technology of heat dissipation effect and clutch, applied in the field of clutch, can solve the problems affecting clutch stability, friction disc wear, friction disc burning, etc., to reduce the risk of burning, work efficiently and stably, and prolong the working life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

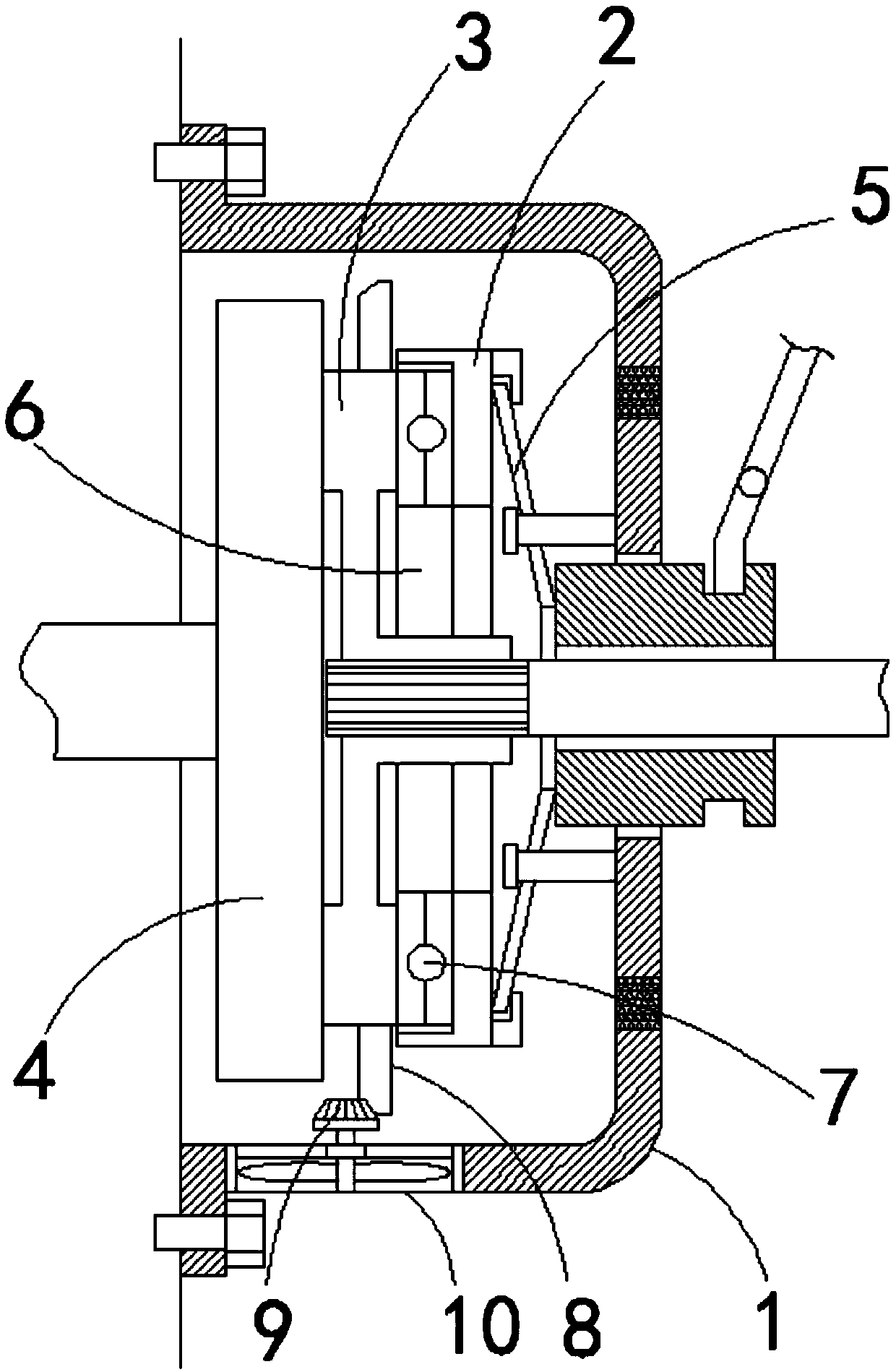

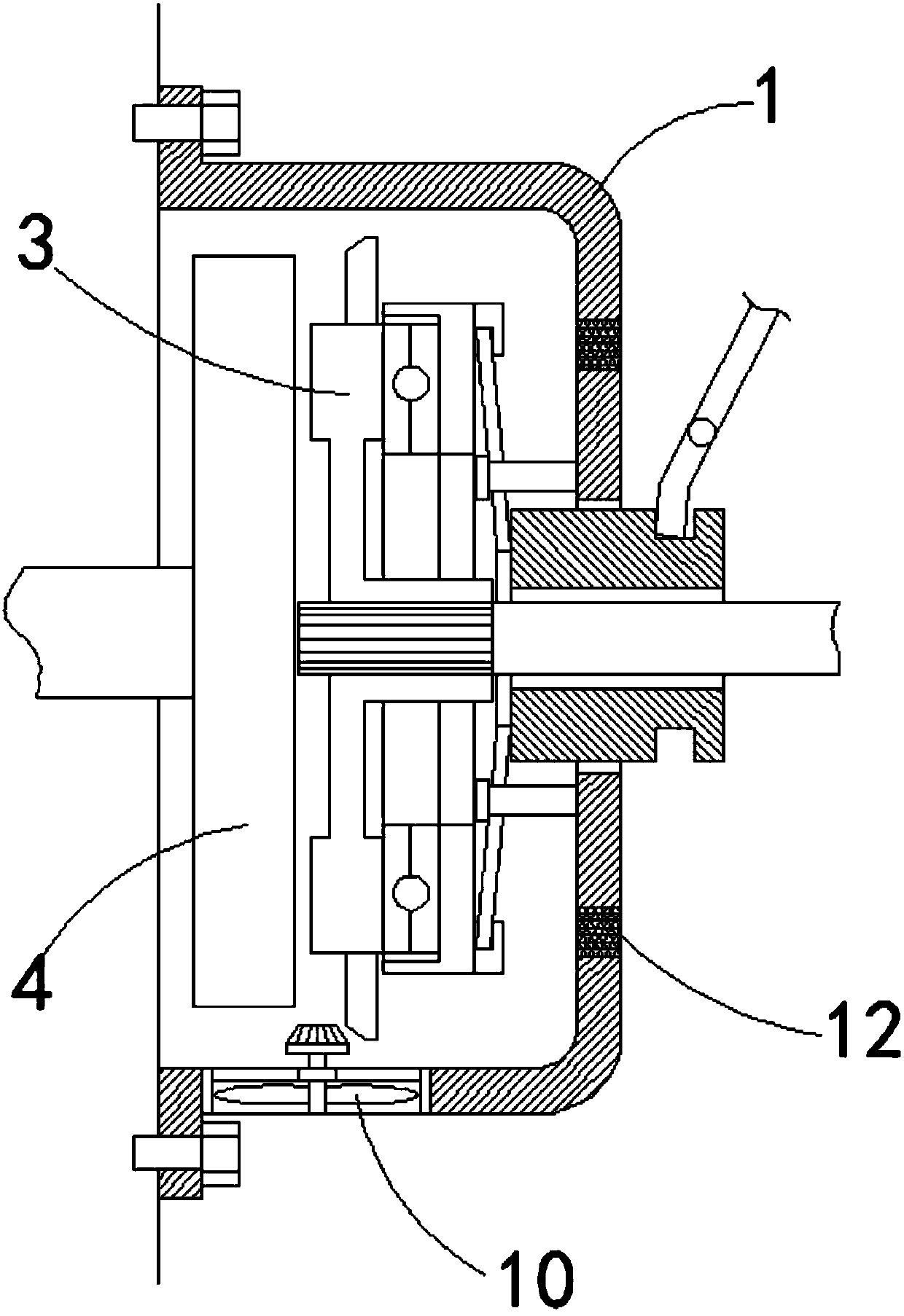

[0018] refer to Figure 1-2 The impeller shaft of the axial flow fan 10 extends to the inside of the casing 1, and a helical gear 9 is fixedly connected to the upper end of the impeller shaft. The helical gear 9 is located on the side of the ring 8 away from the pressure plate 2. One edge is provided with a first chamfer, and the first chamfer is evenly distributed with tooth grooves matching the helical gear 9. When the clutch is released, the helical gear 9 meshes with the tooth grooves, and the flywheel 4 drives the friction plate 3 to rotate. Then drive the axial flow fan 10 to rotate, and the heat generated by friction is quickly discharged. When the clutch is in the depressed state, the helical gear 9 is separated from the tooth groove, and the axial flow fan 10 stops rotating. The air outlet is discharged; the ring member 8 is connected with the axial flow fan 10 through gear transmission, which can avoid the problems of slipping and frictional loss.

Embodiment 2

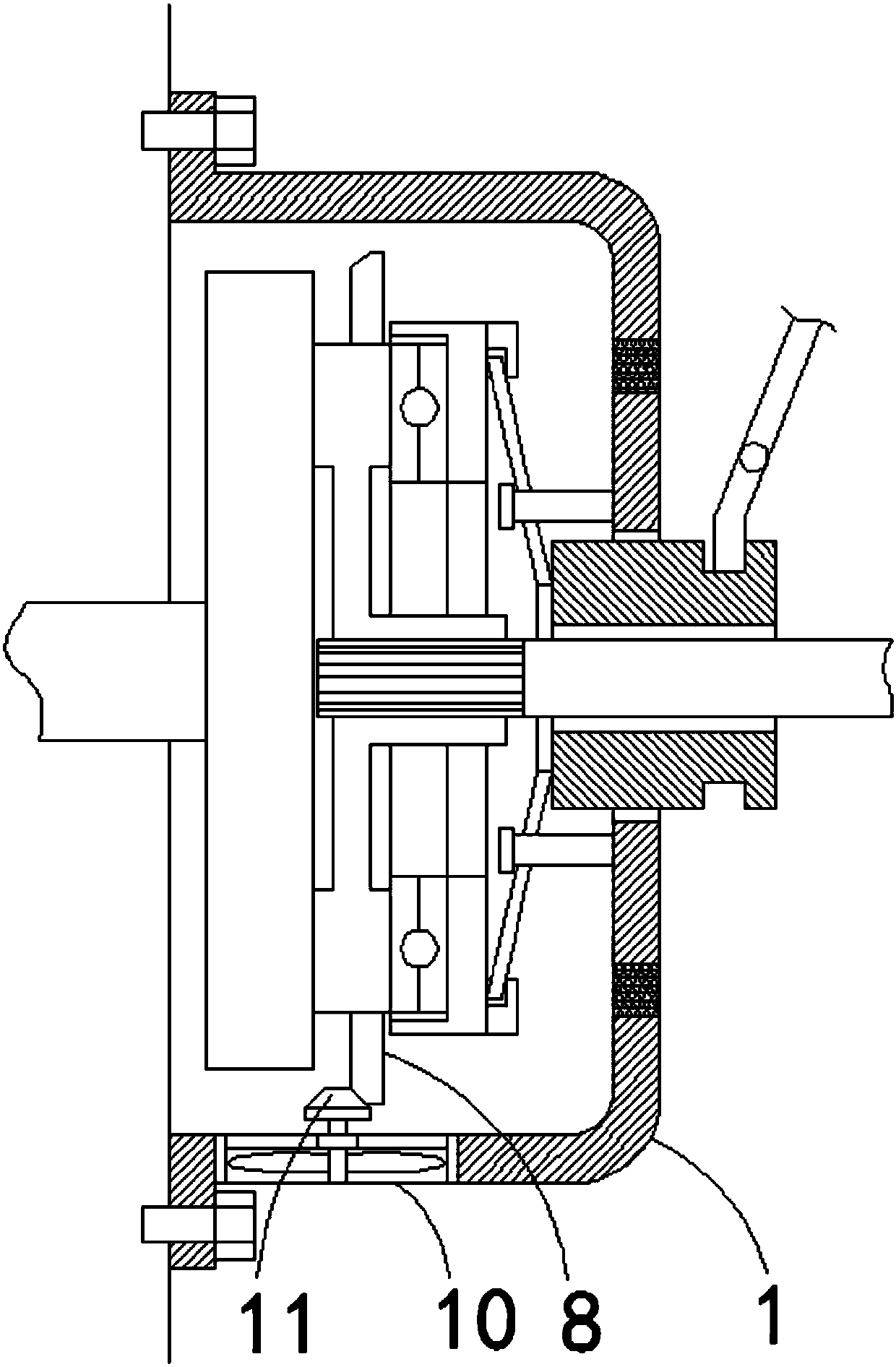

[0020] refer to image 3 The impeller shaft of the axial flow fan 10 extends to the inside of the casing 1, and a friction wheel 11 is fixedly connected to the upper end of the impeller shaft. One side edge is provided with a third chamfer. When the clutch is released, the helical gear 9 meshes with the tooth groove, and the flywheel 4 drives the friction plate 3 to rotate, which in turn drives the axial flow fan 10 to quickly discharge the heat generated by friction. When the clutch is in the depressed state, the helical gear 9 is disengaged from the tooth groove, the axial flow fan 10 stops rotating, and the wear debris generated when the friction plate 3 is working is discharged from the air outlet; the friction transmission method can avoid the sudden rotation of the friction plate 3 As a result, the toothing phenomenon occurs, which in turn affects the life of the friction wheel 3 .

[0021] In the present invention, a groove 6 is provided on the pressure plate 2, a thru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com