Manual electric soldering bit capable of increasing welding efficiency of lead and bonding pad and improving welding reliability of lead and bonding pad

A technology for electric soldering iron tips and welding efficiency, which is applied in the direction of soldering irons, welding equipment, manufacturing tools, etc., can solve the problems of microstructural differences inside the weld, prolong the preheating and welding time, and reduce the reliability of solder joints, etc., to achieve shortening The effect of shortening welding time and preheating time and reducing the risk of burnout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

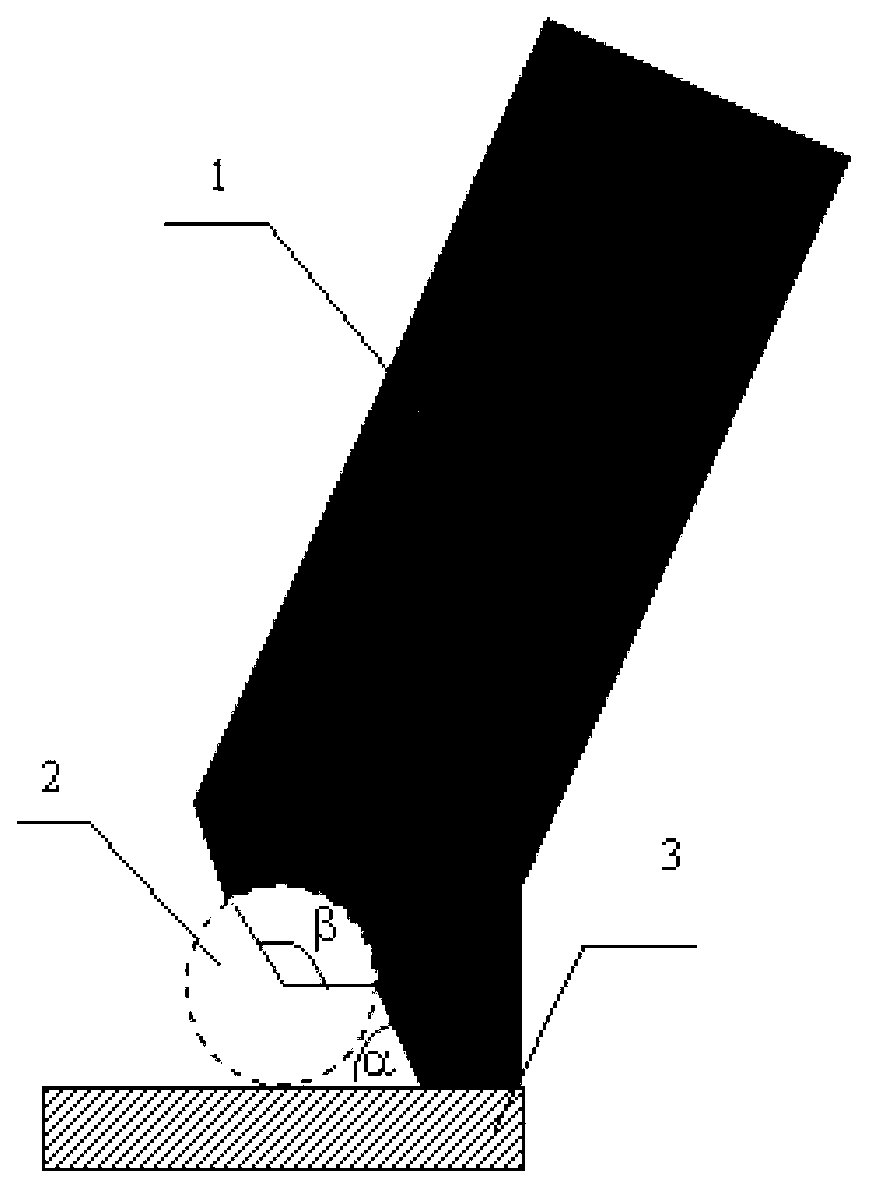

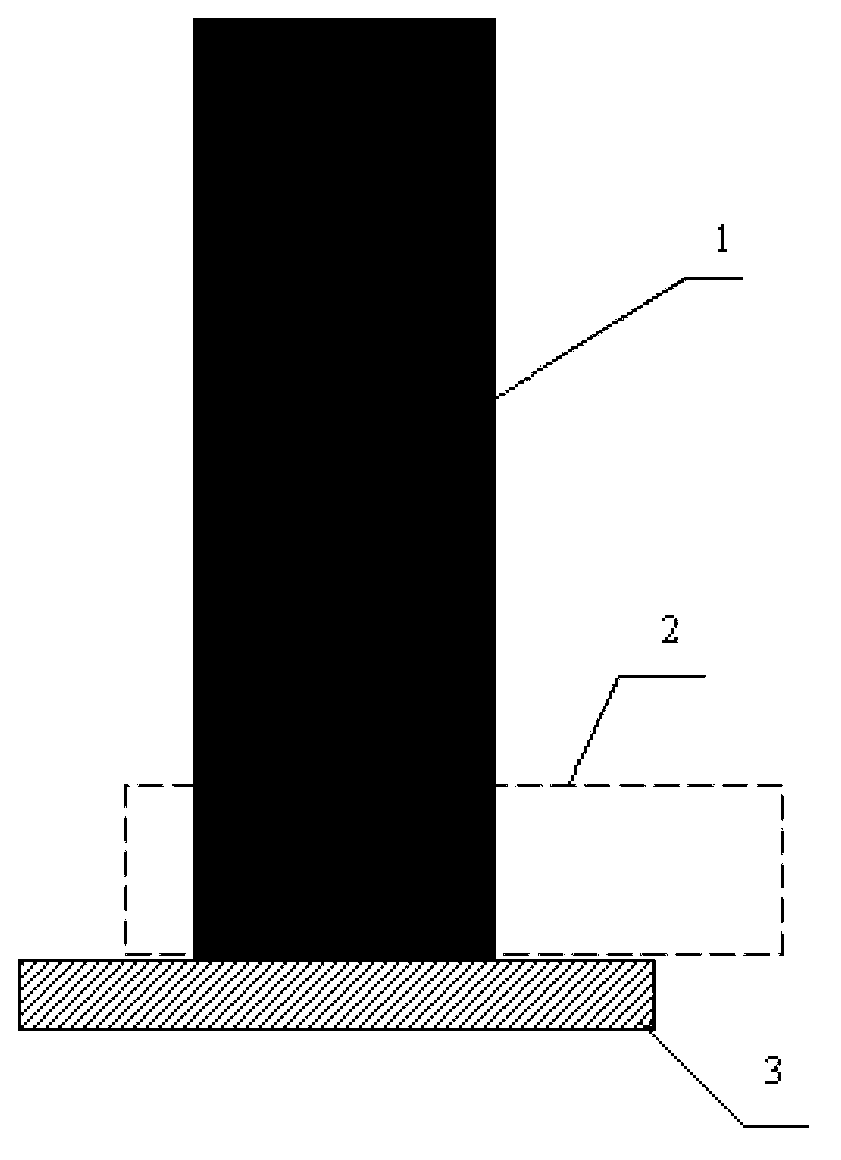

[0013] Embodiment 1: There is a gap in the middle of the tip end of the electric soldering iron, and the right part of the gap is longer than the left part of the gap.

[0014] The present invention includes the following advantages:

[0015] 1. Due to the design of the heat transfer structure of the electric soldering iron head, the heat transfer efficiency of the electric soldering iron, the wire and the pad can be improved, the preheating time before welding is shortened, and the risk of the circuit board being burned is reduced;

[0016] 2. The structure of the soldering iron head can ensure that the wire and pad quickly rise to the temperature to be soldered, and the temperature is uniform throughout the length of the wire and pad to be soldered. Therefore, in the process of adding welding wire to manual welding, the solder will quickly wet and spread on the surface of the wire to be welded and the metal surface of the pad, which will effectively shorten the welding time;...

specific Embodiment approach 2

[0020] Specific Embodiment 2: This embodiment differs from Specific Embodiment 1 in that: the shape of the notch is arc-shaped, triangular or square. Other structures and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Embodiment 3: This embodiment is different from Embodiment 1 in that: the bottom of the right part of the notch is a flat bottom, a pointed bottom or an arc-shaped bottom. Other structures and connections are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com