Tarpaulin structure

A waterproof cover, substructure technology, applied in the direction of roof, transportation and packaging, vehicle components, etc., can solve the problem that the top frame cannot be operated from one side

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

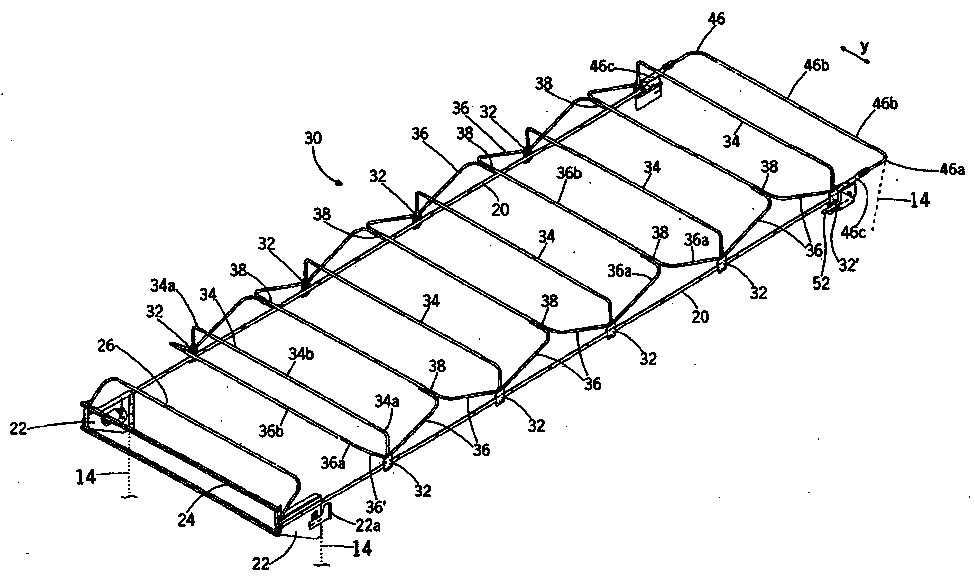

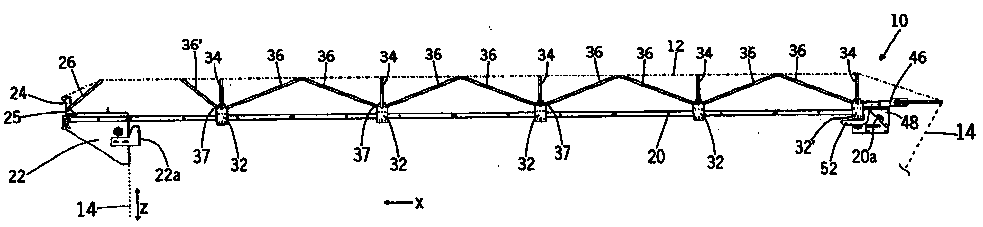

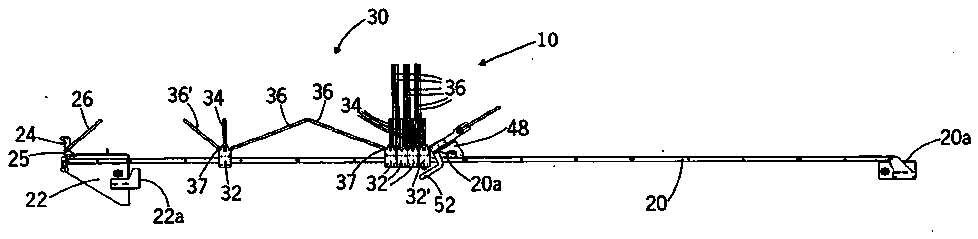

[0101] figure 2 A side view of the flashing structure 10 is illustrated in detail, wherein the flashing is marked by dashed lines and is not detailed in the following figures for better illustration. Further, dashed lines are used to illustrate that the outline feature of the container 14 directly above the top frame 16 is created. For example, the container 14 is a sloped structure capable of receiving debris or other dusty material, and for this reason, coverage by the waterproof cover structure 10 is preferred, in some cases, for transport purposes in heavy duty vehicles.

[0102] The waterproof cover structure 10 is respectively connected with a guide rail track 20 on both sides of the side outer wall of the container 14. The guide rail track is composed of many guide rail track sections fixed on the outer wall of the container, so as to form a distance with the outer wall of the container, such as by rivets, screws or other Appropriate fixing means make it possible to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com