Material storing device having cooling and heat dissipation structure and working method thereof

A heat dissipation structure and material storage technology, applied in fruit hanging devices, botanical equipment and methods, anti-corrosion coatings, etc., can solve the problems affecting the cooling and heat dissipation effect of granaries, the uncontrollable external air temperature, applicability and practical limitations, etc. , to achieve good practicability, improve ventilation and heat dissipation performance, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

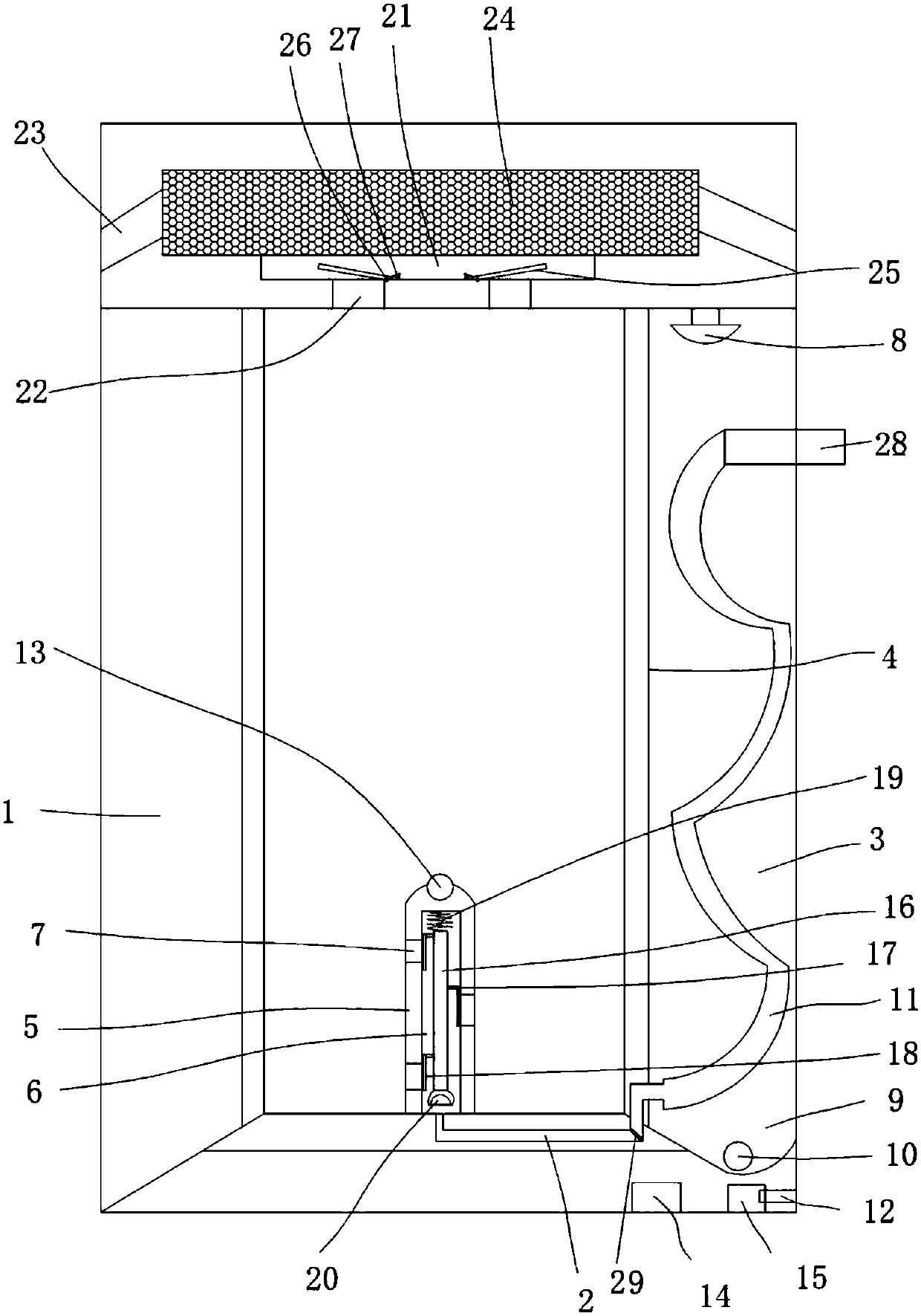

[0021] Such as figure 1 The shown material storage device with a cooling and heat dissipation structure includes a bin body 1, an air passage 2 arranged on the bin body 1, a cavity 3 is provided in the side wall of the bin body 1, and a cavity 3 is arranged in the side wall of the bin body 1. A heat insulation board 4 is arranged in the cavity 3, a vertical pole 5 is evenly arranged on the bottom wall of the warehouse body 1, and a guide tube communicating with the air passage 2 is arranged in the vertical pole 5. The wind channel 6 is provided with an air hole 7 communicating with the air guide channel 6 on the vertical pole 5, and a water spray nozzle 8 is provided on the top wall of the cavity 3. A water collection chamber 9 is arranged on the bottom wall of the chamber 3, and a water pump 10 is fixed in the water collection chamber 9, and the water pump 10 is connected with the water nozzle 8, and a spiral Shaped air guide pipe 11, one end of the spiral air guide pipe 11 ...

Embodiment 2

[0028] Such as figure 1The shown material storage device with a cooling and heat dissipation structure includes a bin body 1, an air passage 2 arranged on the bin body 1, a cavity 3 is provided in the side wall of the bin body 1, and a cavity 3 is arranged in the side wall of the bin body 1. A heat insulation board 4 is arranged in the cavity 3, a vertical pole 5 is evenly arranged on the bottom wall of the warehouse body 1, and a guide tube communicating with the air passage 2 is arranged in the vertical pole 5. The wind channel 6 is provided with an air hole 7 communicating with the air guide channel 6 on the vertical pole 5, and a water spray nozzle 8 is provided on the top wall of the cavity 3. A water collection chamber 9 is arranged on the bottom wall of the chamber 3, and a water pump 10 is fixed in the water collection chamber 9, and the water pump 10 is connected with the water nozzle 8, and a spiral Shaped air guide pipe 11, one end of the spiral air guide pipe 11 i...

Embodiment 3

[0035] Such as figure 1 The shown material storage device with a cooling and heat dissipation structure includes a bin body 1, an air passage 2 arranged on the bin body 1, a cavity 3 is provided in the side wall of the bin body 1, and a cavity 3 is arranged in the side wall of the bin body 1. A heat insulation board 4 is arranged in the cavity 3, a vertical pole 5 is evenly arranged on the bottom wall of the warehouse body 1, and a guide tube communicating with the air passage 2 is arranged in the vertical pole 5. The wind channel 6 is provided with an air hole 7 communicating with the air guide channel 6 on the vertical pole 5, and a water spray nozzle 8 is provided on the top wall of the cavity 3. A water collection chamber 9 is arranged on the bottom wall of the chamber 3, and a water pump 10 is fixed in the water collection chamber 9, and the water pump 10 is connected with the water nozzle 8, and a spiral Shaped air guide pipe 11, one end of the spiral air guide pipe 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com