Pigsty for breeding fragrant pigs

A technology for breeding fragrant pigs and pig houses, applied in the field of animal husbandry, can solve the problems of fragrant pigs with diseases, temperature drop, and difficulty in controlling ventilation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

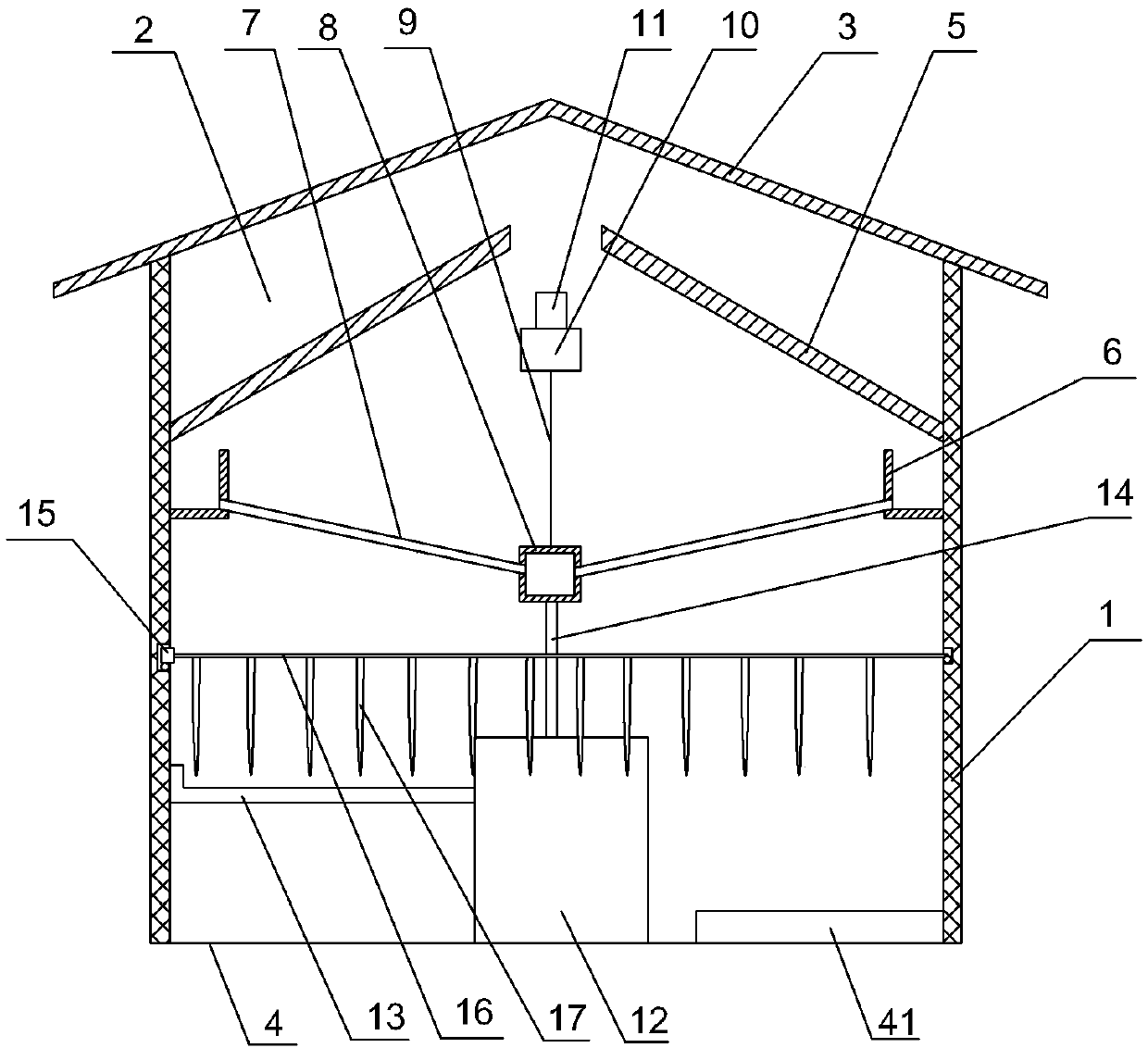

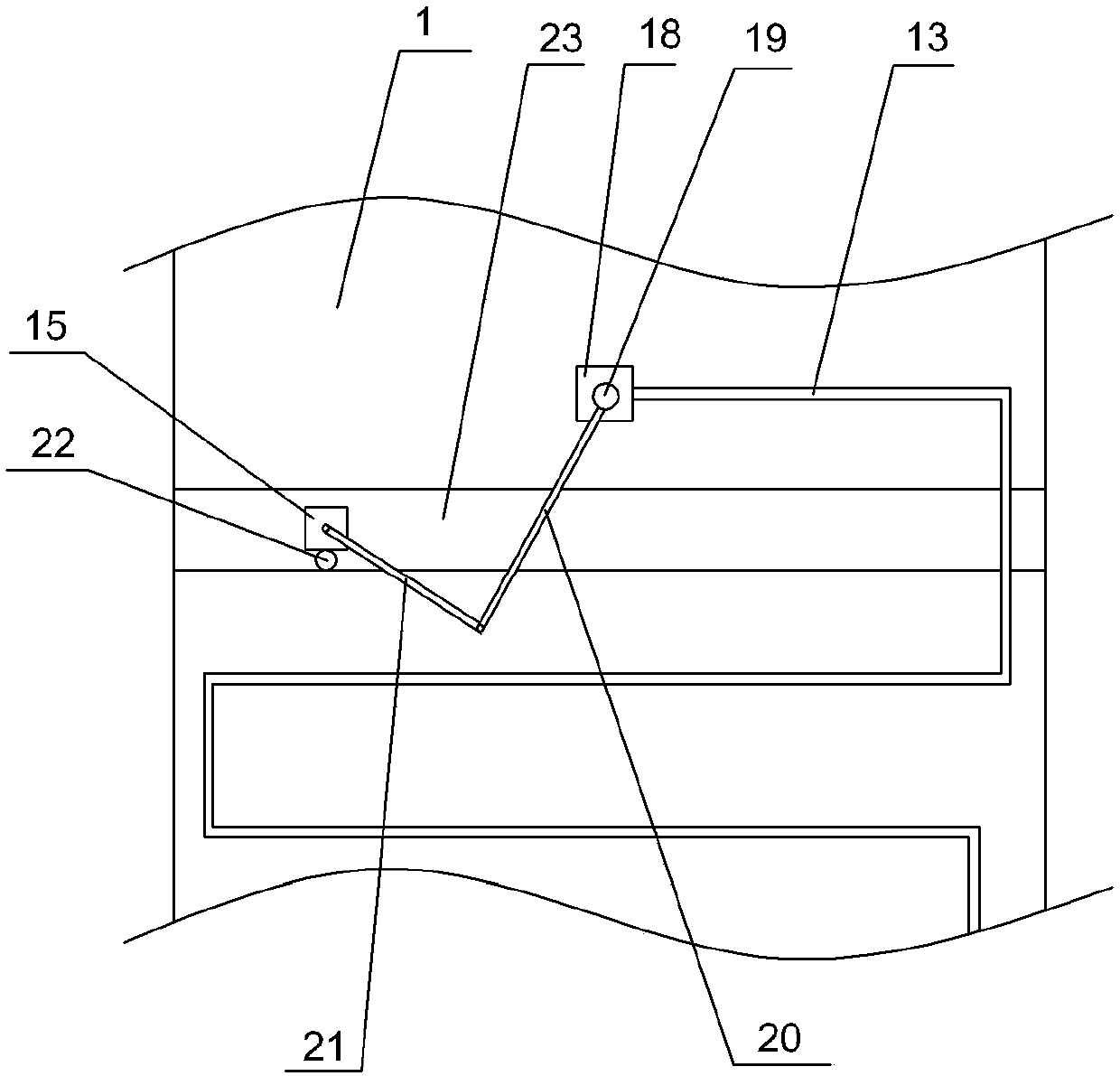

[0026] Such as figure 1 with figure 2 As shown, the piggery for breeding fragrant pigs of the present embodiment includes four side walls 1, and the four side walls 1 are connected end to end to form a breeding room 2, and the bottom surface of the breeding room 2 is laid with a floor 4 made of cement, wherein A rectangular air vent 11 is provided at the top of a side wall 1, and two condensing plates 5 are fixedly installed on the two side walls 1 adjacent to the air vent 11, and the two condensing plates 5 are all inclined. A sump 6 is respectively provided at the lower end of the bottom, and the two sumps 6 are installed on the side wall 1 .

[0027] A shutter 10 is slidably arranged in the air vent 11, and the area of the shutter 10 is larger than that of the air vent 11. A spring (not shown) is connected between the upper end of the shutter 10 and the side wall 1 for the reset of the shutter 10. The lower end of the board 10 is fixedly connected with a rigid rope 9, ...

Embodiment 2

[0032] The difference between the present embodiment and the first embodiment is that in the present embodiment, the steam pipes 13 are attached to the four side walls 1 and the floor 4, so that the breeding room 2 can be heated and kept warm in all directions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com