Garbage picking manipulator

A technology of manipulators and garbage, applied in the field of manipulators, can solve the problem of single types of garbage, achieve safe and simple operation, reduce the number of times of bending, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

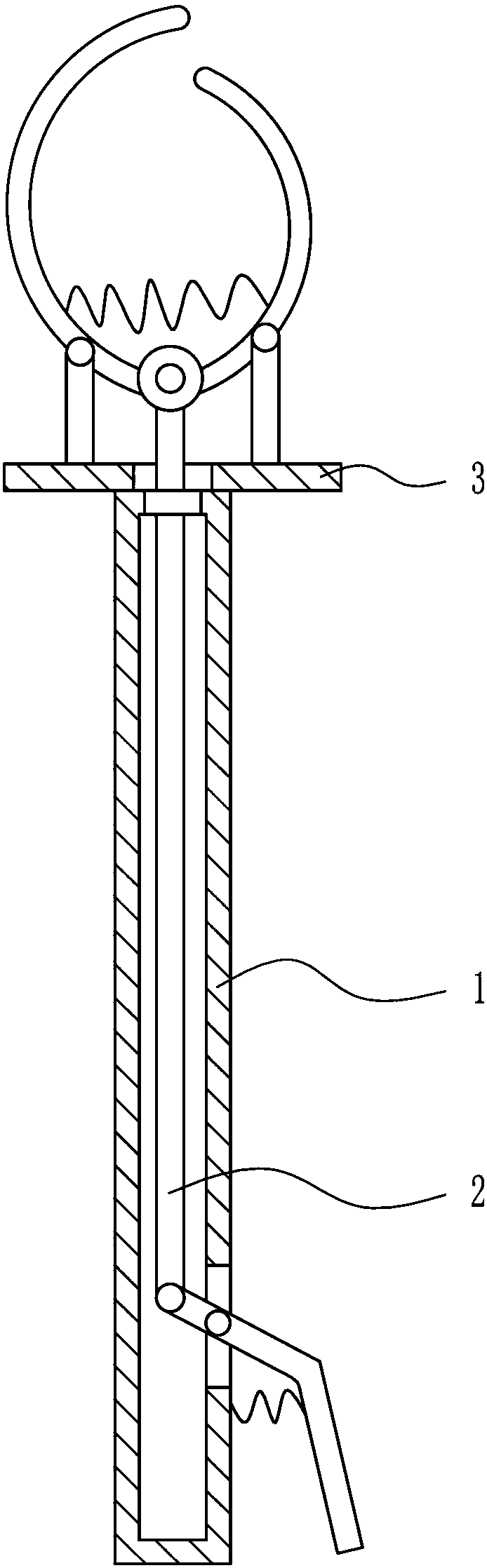

[0028] A garbage picking robot, such as Figure 1-5 As shown, it includes a hollow pole 1, an opening device 2 and a clamping device 3. The hollow pole 1 is provided with an opening device 2, the top of the hollow pole 1 is provided with a clamping device 3, and the bottom of the clamping device 3 is connected with the opening device. 2 top connections.

Embodiment 2

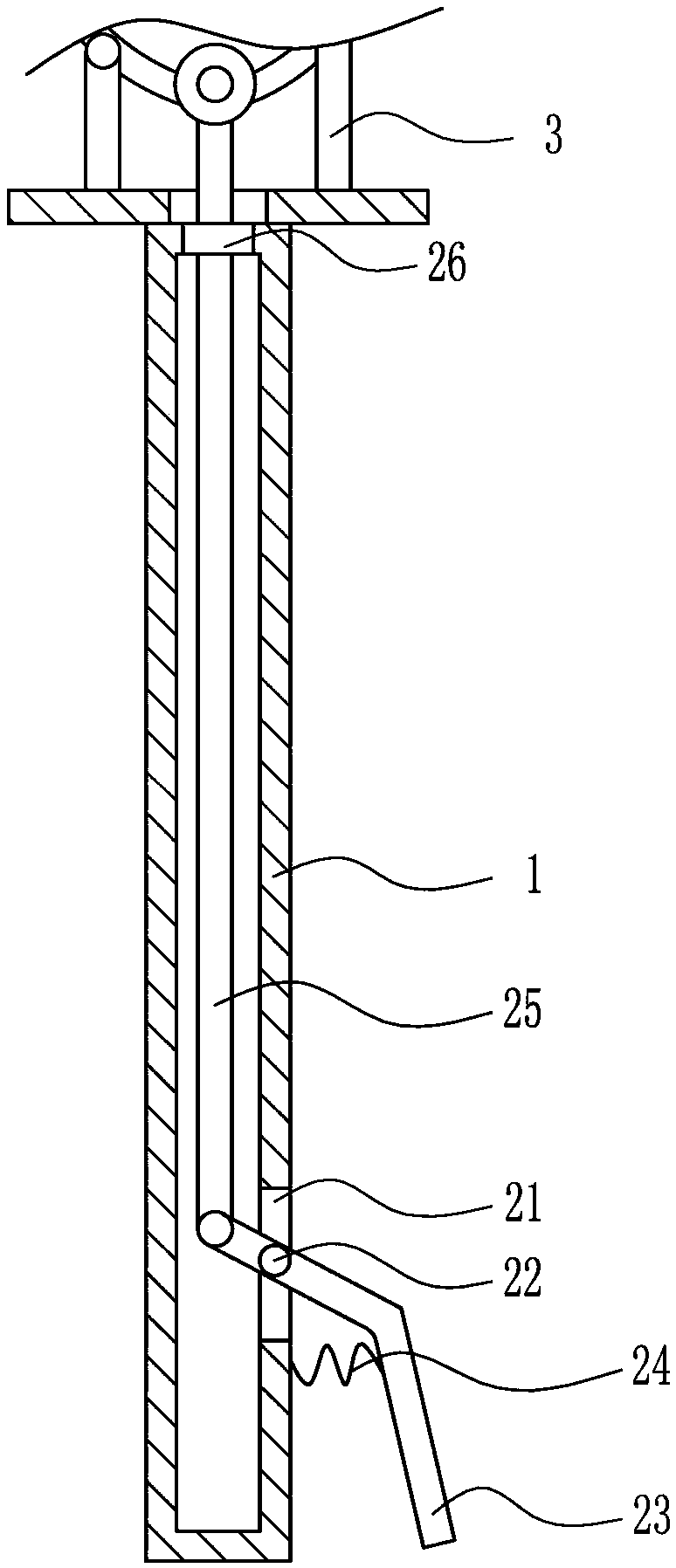

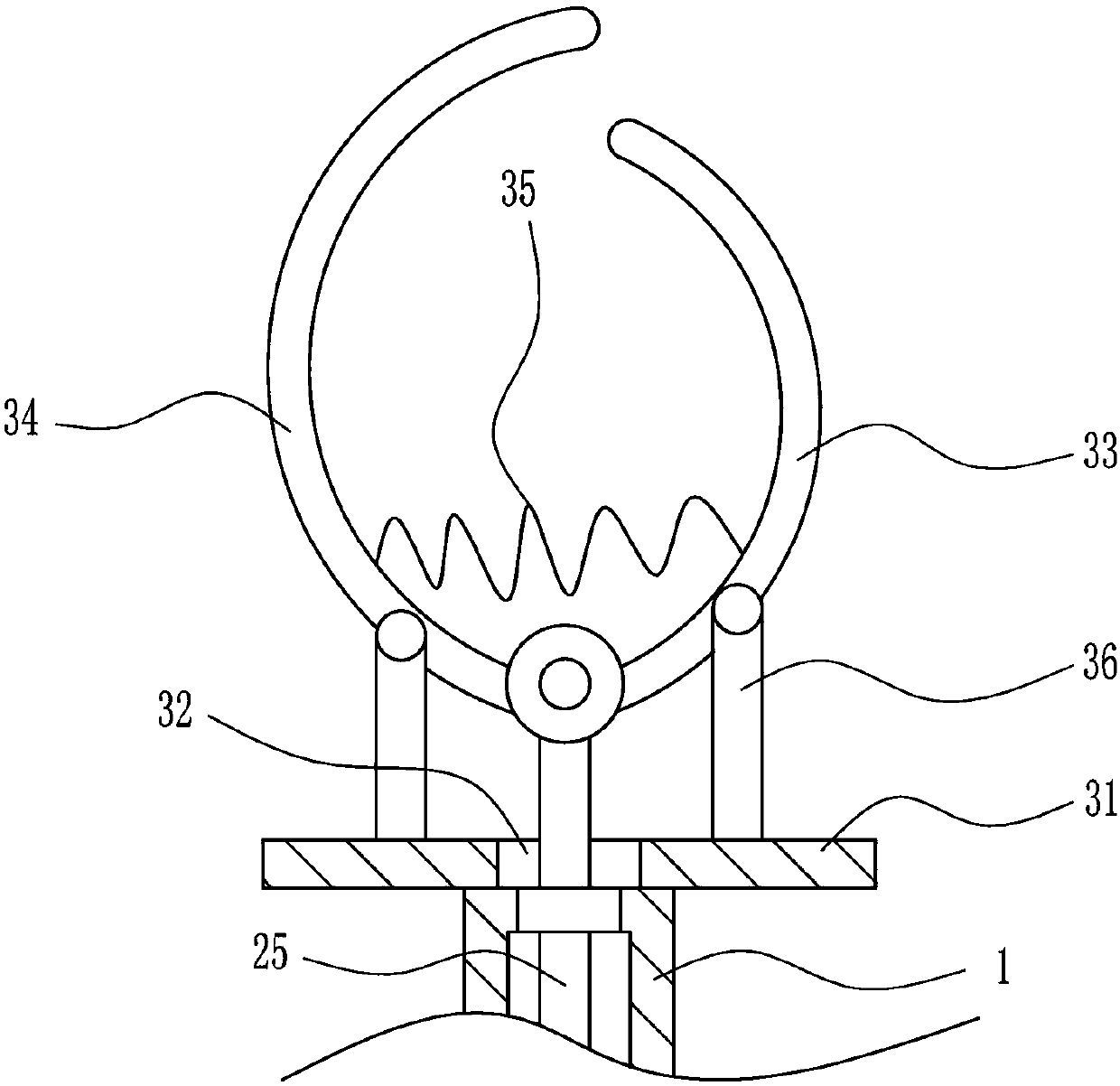

[0030] A garbage picking robot, such as Figure 1-5 As shown, it includes a hollow pole 1, an opening device 2 and a clamping device 3. The hollow pole 1 is provided with an opening device 2, the top of the hollow pole 1 is provided with a clamping device 3, and the bottom of the clamping device 3 is connected with the opening device. 2 top connections.

[0031] The opening device 2 includes a pin shaft 22, a handle 23, a first spring 24, a connecting rod 25 and a guide sleeve 26; Pin shaft 22, a handle 23 is arranged on the pin shaft 22, the left part of the handle 23 is located in the hollow strut 1, a first spring 24 is connected between the left middle part of the handle 23 and the right lower part of the hollow strut 1, and the left end of the handle 23 rotates Connecting rod 25 is connected in the formula, and the center of hollow strut 1 top is provided with guide sleeve 26, and the top of connecting rod 25 passes through guide sleeve 26 and is connected with clamping ...

Embodiment 3

[0033]A garbage picking robot, such as Figure 1-5 As shown, it includes a hollow pole 1, an opening device 2 and a clamping device 3. The hollow pole 1 is provided with an opening device 2, the top of the hollow pole 1 is provided with a clamping device 3, and the bottom of the clamping device 3 is connected with the opening device. 2 top connections.

[0034] The opening device 2 includes a pin shaft 22, a handle 23, a first spring 24, a connecting rod 25 and a guide sleeve 26; Pin shaft 22, a handle 23 is arranged on the pin shaft 22, the left part of the handle 23 is located in the hollow strut 1, a first spring 24 is connected between the left middle part of the handle 23 and the right lower part of the hollow strut 1, and the left end of the handle 23 rotates Connecting rod 25 is connected in the formula, and the center of hollow strut 1 top is provided with guide sleeve 26, and the top of connecting rod 25 passes through guide sleeve 26 and is connected with clamping d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com