Blood meal protein wood preservative and preparation method thereof

A wood preservative and blood meal technology, applied in wood treatment, wood impregnation, wood impregnation, etc., can solve the problems of human and surrounding environment hazards and pollution, unfavorable environmental protection, low loss resistance, etc., and achieve good color and good anti-corrosion. effect, the effect of improving the fixing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0024] Example 1

[0025] A blood meal protein wood preservative is characterized in that it comprises the following components:

[0026] 6 parts of copper sulfate;

[0027] 8 parts of borax;

[0028] 20 parts of blood meal protein acid hydrolyzate;

[0029] The blood meal protein acid hydrolyzate is obtained by concentrating soybean dregs after pyrolysis, and the protein mass concentration in the blood meal protein acid hydrolyzate is 60%.

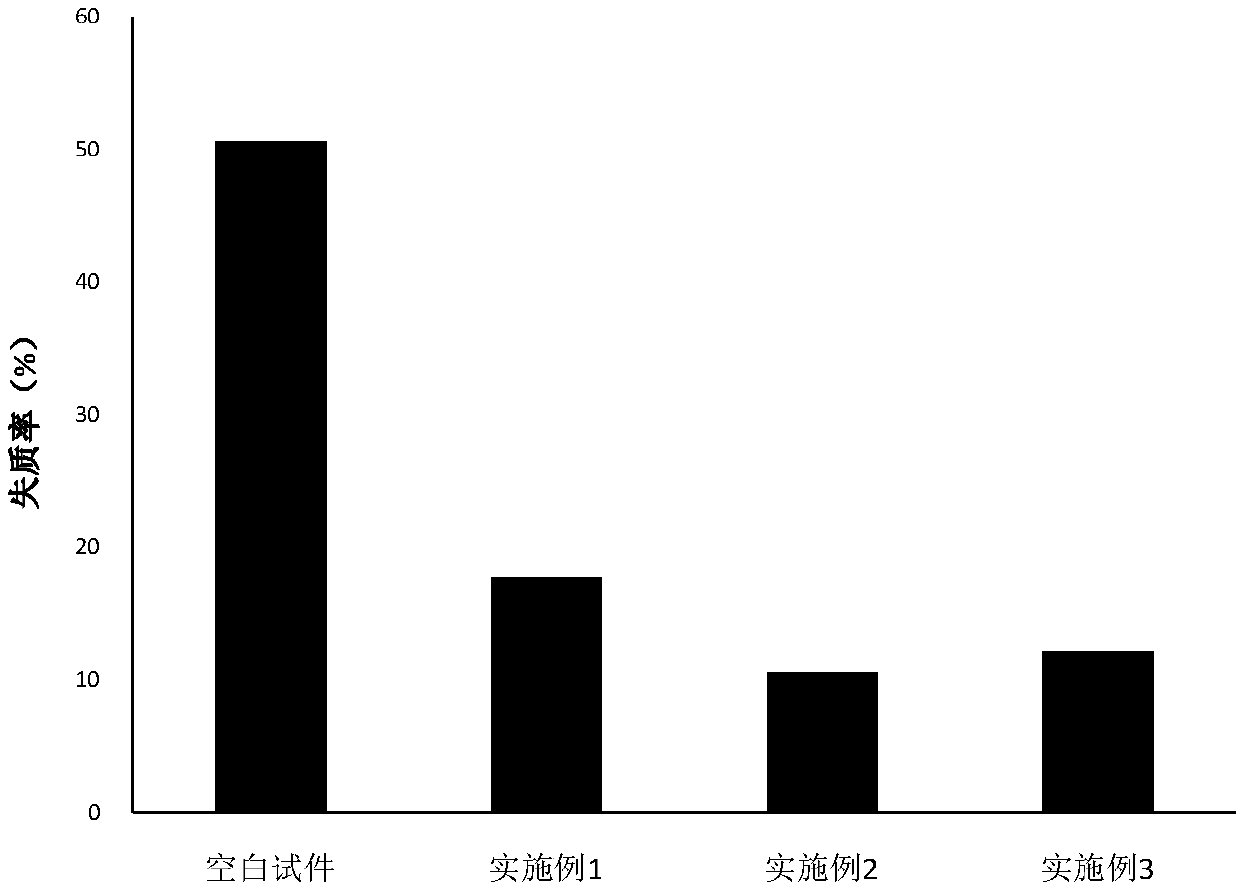

[0030] The wood preservative has chelated amino acid copper boron salt, which has good fixation. After entering the wood, it can form a water-insoluble polymer network inside the wood, thereby improving the copper and boron in the wood. The fixation performance in the wood achieves the purpose of long-term anticorrosion. Compared with the blank specimen, the treated wood has no obvious change and the color is uniform. It can be considered that the preservative has basically no effect on the color of the wood. Comparing the appearance ...

Example Embodiment

[0031] Example 2

[0032] A blood meal protein wood preservative is characterized in that it comprises the following components:

[0033] 4 parts copper sulfate;

[0034] 5 parts of borax;

[0035] 15 parts of blood meal protein acid hydrolyzate;

[0036] The blood meal protein acid hydrolyzate is obtained by concentrating soybean dregs after pyrolysis, and the protein mass concentration in the blood meal protein acid hydrolyzate is 60%.

[0037] The wood preservative has chelated amino acid copper boron salt, which has good fixation. After entering the wood, it can form a water-insoluble polymer network inside the wood, thereby improving the copper and boron in the wood. The fixation performance in the wood achieves the purpose of long-term anticorrosion. Compared with the blank specimen, the treated wood has no obvious change and the color is uniform. It can be considered that the preservative has basically no effect on the color of the wood. Comparing the appearance of ...

Example Embodiment

[0038] Example 3

[0039] A blood meal protein wood preservative is characterized in that it comprises the following components:

[0040] 6 parts of copper sulfate;

[0041] 8 parts of borax;

[0042] 25 parts of blood meal protein acid hydrolyzate;

[0043] The blood meal protein acid hydrolyzate is obtained by concentrating soybean dregs after pyrolysis, and the protein mass concentration in the blood meal protein acid hydrolyzate is 62%.

[0044] The wood preservative has chelated amino acid copper boron salt, which has good fixation. After entering the wood, it can form a water-insoluble polymer network inside the wood, thereby improving the copper and boron in the wood. The fixation performance in the wood achieves the purpose of long-term anticorrosion. Compared with the blank specimen, the treated wood has no obvious change and the color is uniform. It can be considered that the preservative has basically no effect on the color of the wood. Comparing the appearance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com