Quartz slotted rod slotting device

A technology of slotting equipment and slotted bar, applied in the field of quartz slotted bar slotting equipment, can solve the problems of difficulty in taking out the quartz slotted bar, uneven slotting position, fracture of the quartz slotted bar, etc. The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the examples, but not as a basis for limiting the present invention.

[0022] Example.

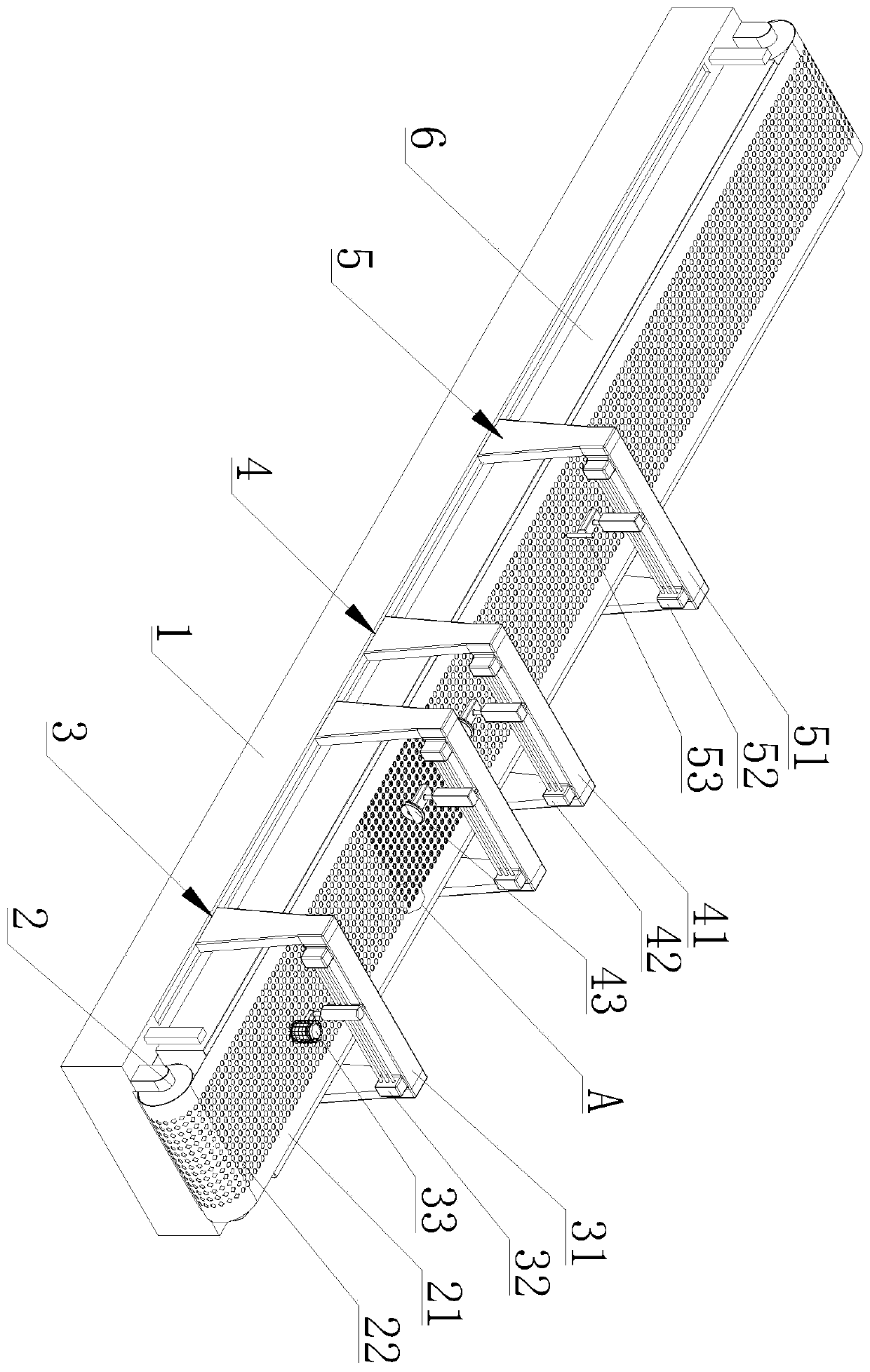

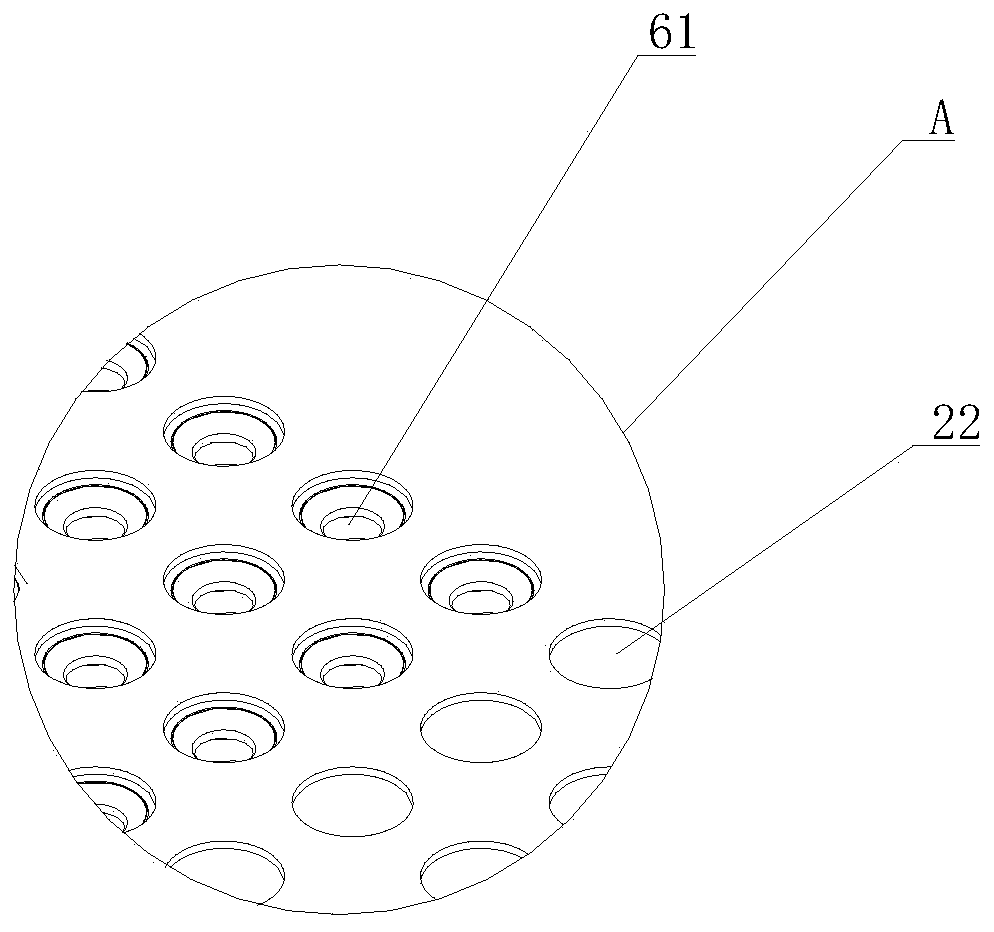

[0023] like Figure 1-3 As shown, a quartz groove bar slotting equipment includes a base 1, on which a conveying device 2 is arranged, and a wax pouring device 3, a slotting device 4 and a wax melting device are sequentially slidably connected to the base 1 along the conveying direction 5. A working platform 6 is provided below the conveying device 2, and a number of vacuum suction cups 61 are provided on the working platform 6 corresponding to the slotting device 4.

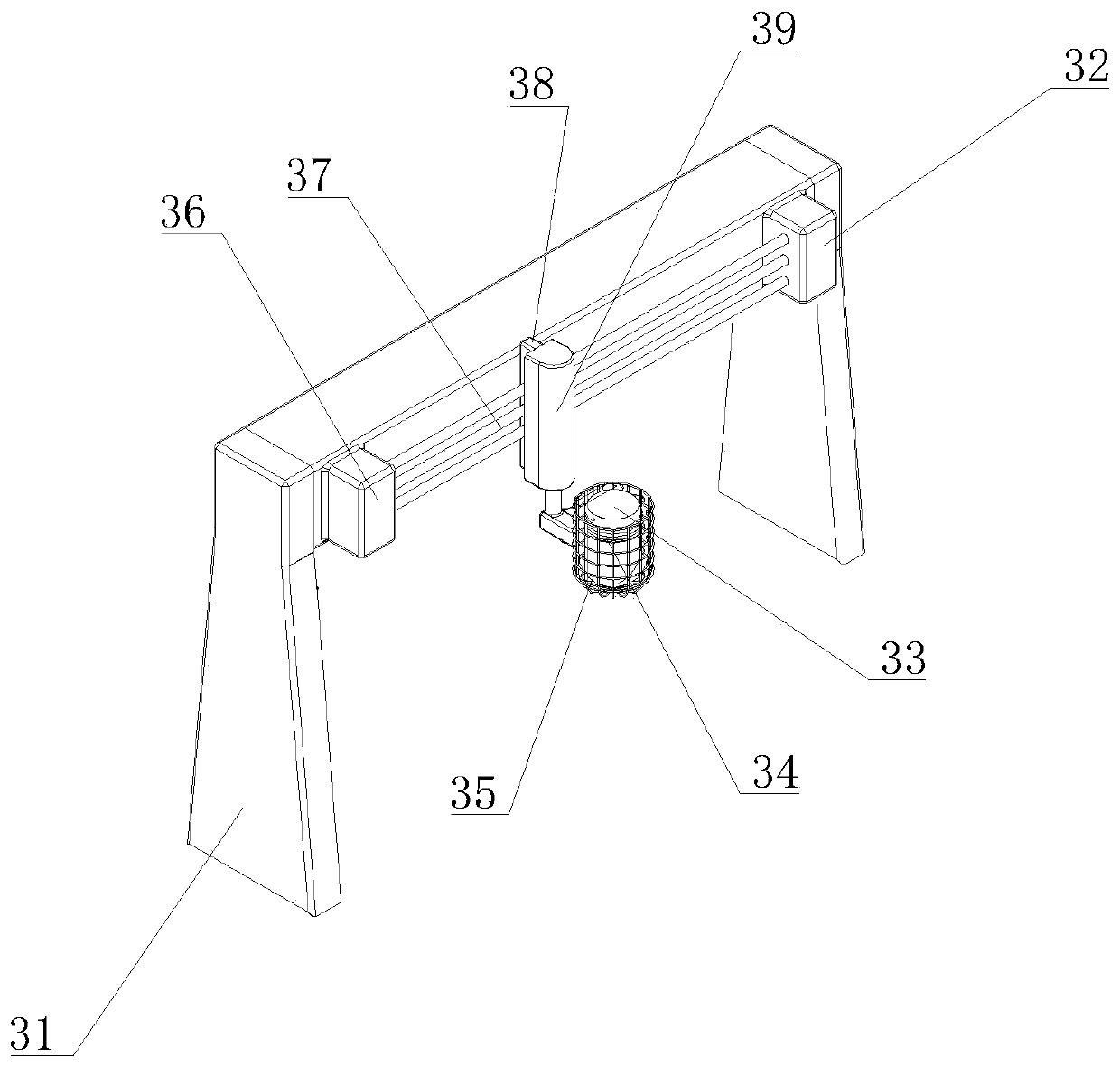

[0024] The wax pouring device 3 comprises a wax pouring installation frame 31, a first two-dimensional moving device 32 is provided on the wax pouring installation frame 31, a wax pouring pot 33 is provided on the first two-dimensional mobile device 32, and the outer periphery of the wax pouring pot 33 A heating wire 34 is surrounded on the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com