Brake device for plate transfer

A braking device and plate technology, applied in the direction of brakes, braking components, vehicle parts, etc., can solve the problems of inconvenience of construction personnel, lack of wallboard equipment, inability to brake and decelerate, etc., and achieve the effect of reducing transportation time and improving work quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

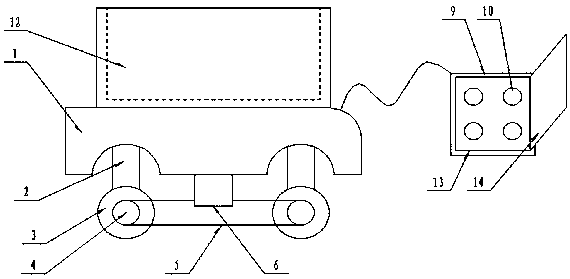

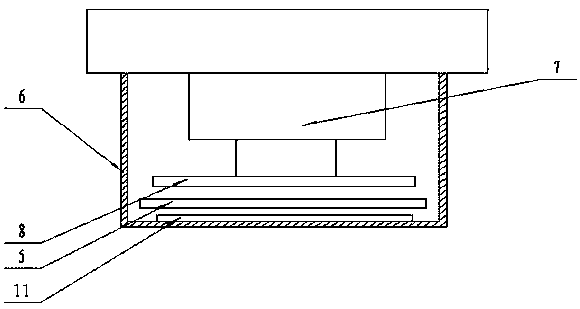

[0013] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-2 As shown, a plate transmission brake device includes a transport trolley (1), the lower end of the transport trolley (1) is provided with a group of rotating shafts (2), and both ends of the group of rotating shafts (2) are provided with runners (3 ), the set of rotating shafts (2) are fitted with pulleys (4), the set of pulleys (4) are fitted with belts (5), and the lower end of the transport trolley (1) is provided with a gantry (6) , the horizontal part of the gantry (6) is lower than the belt (5) and is set on the belt (5), and a telescopic motor (7) with a telescopic direction downward is arranged between the gantry (6), and the telescopic The telescopic end of the motor (7) is provided with a brake pad (8), and the telescopic motor (7) is connected to a remote control box (9); the telescopic motor control switch (10) is provided inside the telescopic The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com