Stacking method of autoclaved fly ash bricks or autoclaved lime sand bricks

A technology of autoclaved fly ash bricks and autoclaved lime-sand bricks, which is applied in the stacking of objects, unstacking of objects, transportation and packaging, etc., which can solve the problems that the mechanical head cannot rotate, low efficiency, limited stacking height, etc. , to achieve the effect of increasing the number of layers arranged, reducing the number of shipments, and improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

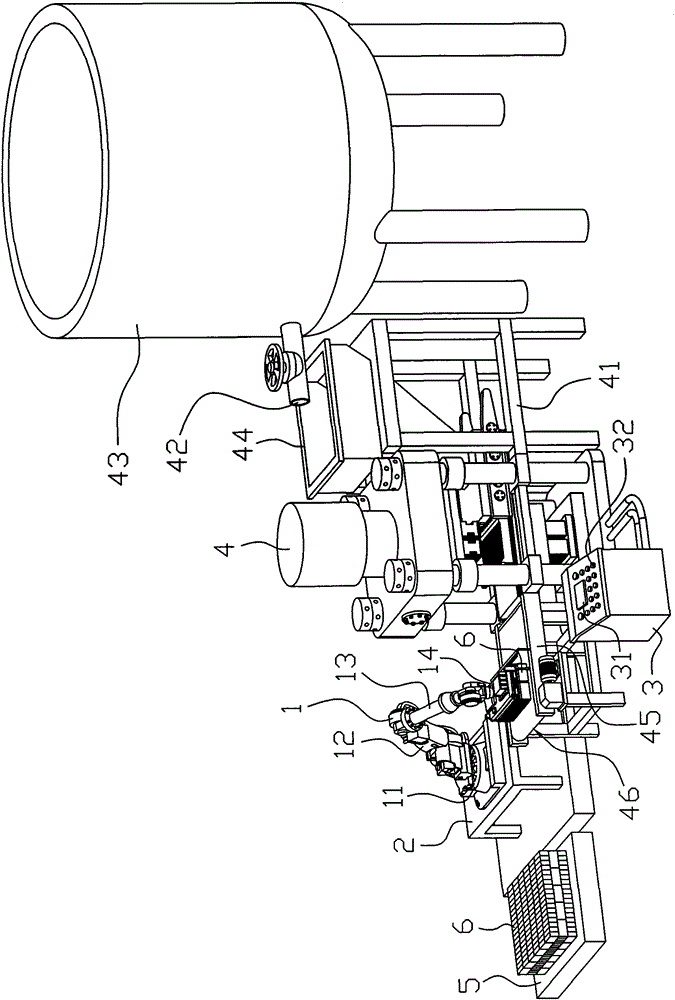

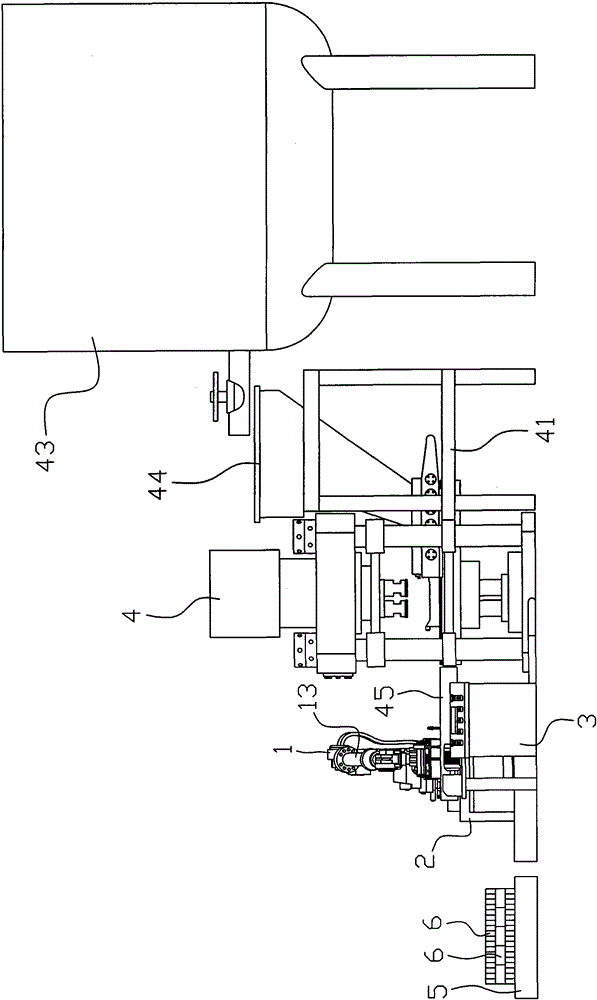

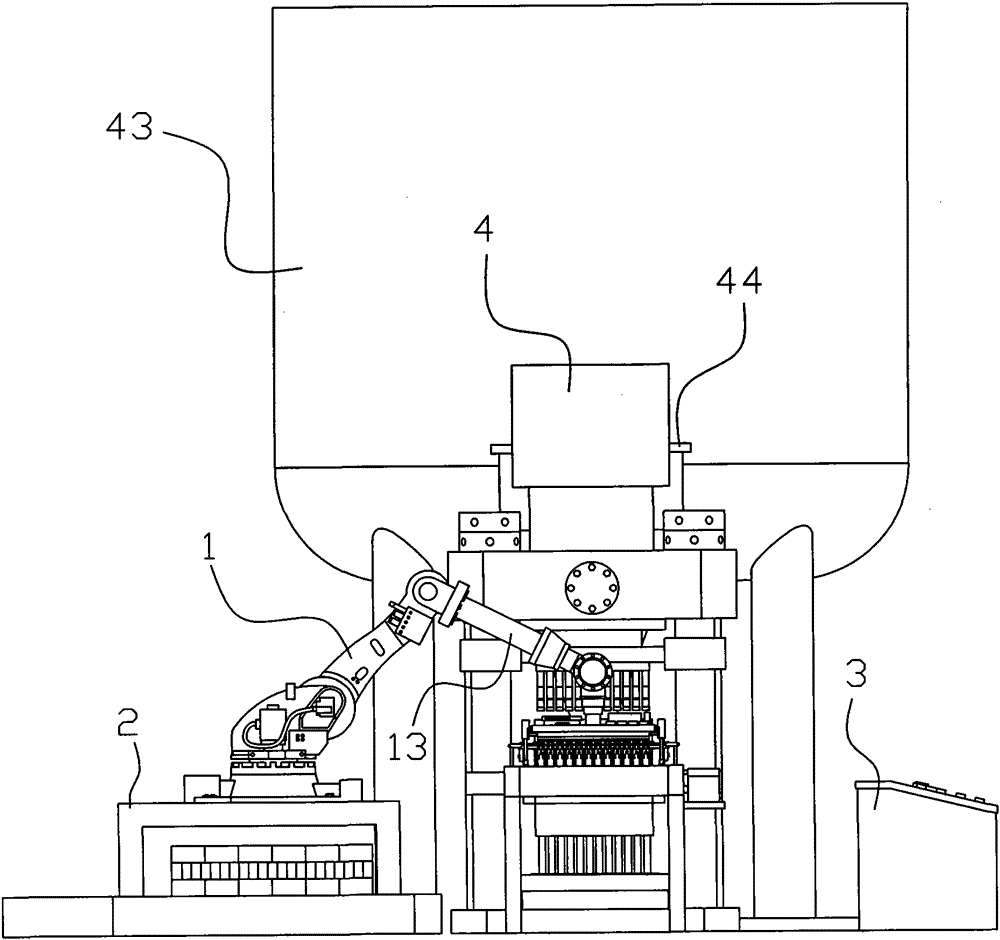

[0017] Such as Figure 1 to Figure 4 As shown, the method for stacking autoclaved fly ash bricks or autoclaved lime-sand bricks in this embodiment includes the following steps: use the gripper 14 in the manipulator 1 to grab the bricks made from the delivery platform 45 of the brick forming machine Bricks 6 are placed on the pallet 5 of the brick delivery car, and the grippers 14 are arranged in one layer every four times to grab and send the bricks 6, and they are stacked vertically upwards successively. Cross-stacking, the manipulator 1 and the brick forming machine are controlled by automatic program control, and the 6 layers of bricks stacked are N layers, and the N is a natural number not greater than 20. Described brick 6 every layer is placed 96, and the gripper 14 in the manipulator 1 grasps and transports 24 at every turn, is stacked...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com