A kind of concrete distributing machine and circular distributing method

A distributing machine and concrete technology, which is applied to the processing of building materials, construction, building construction, etc., can solve the problems of low distributing efficiency, high requirements for construction sites, and poor versatility, and achieve strong versatility, high distributing efficiency, and construction The effect of low site requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereby.

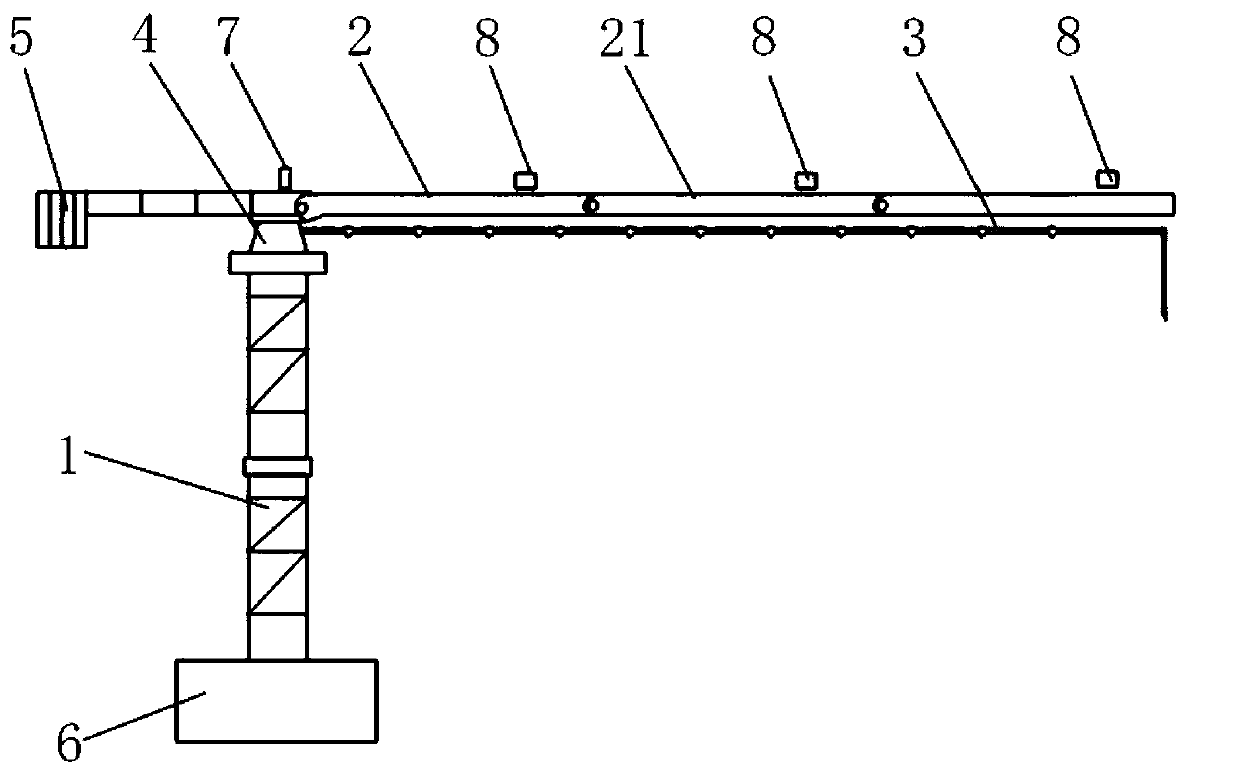

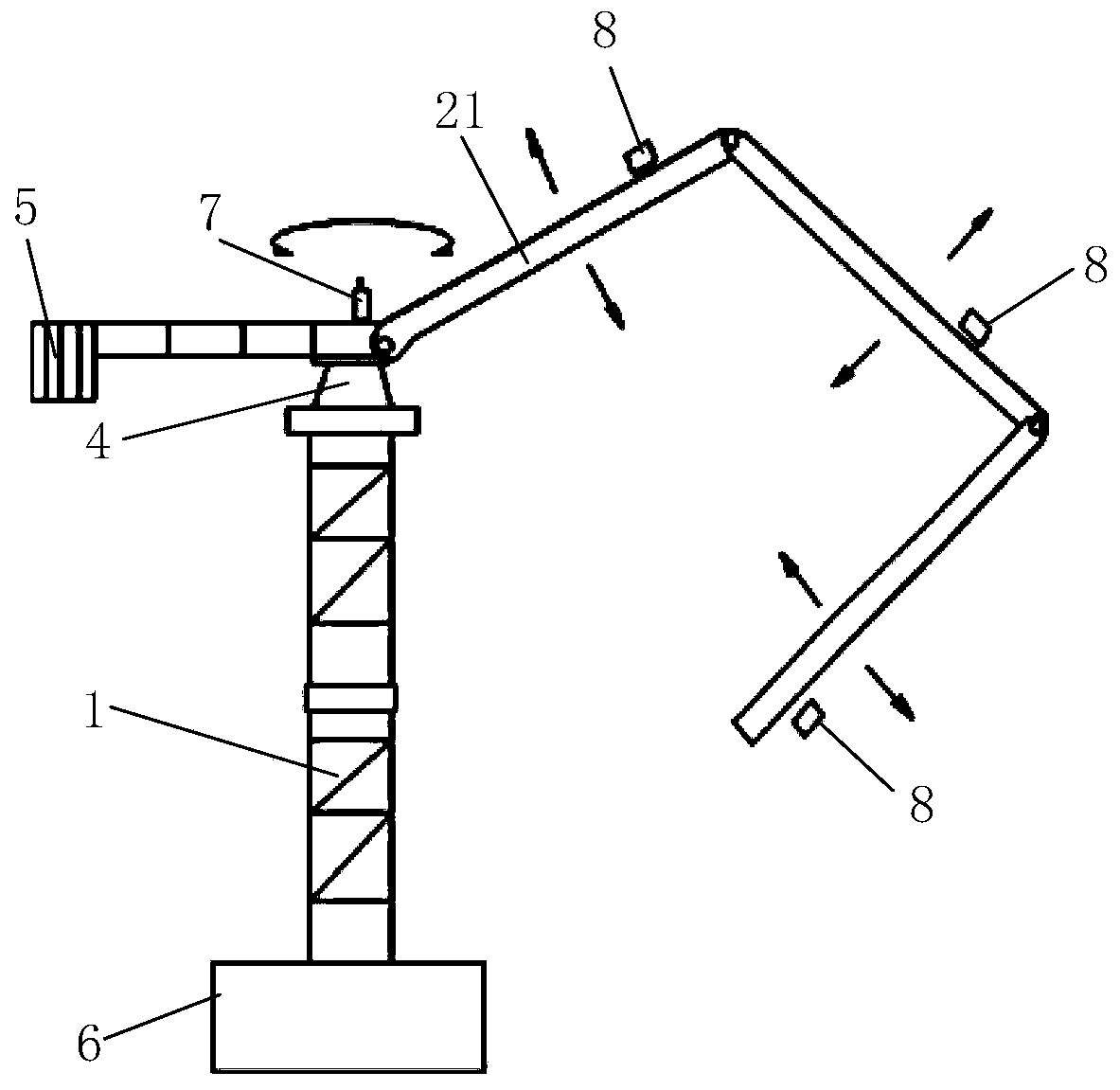

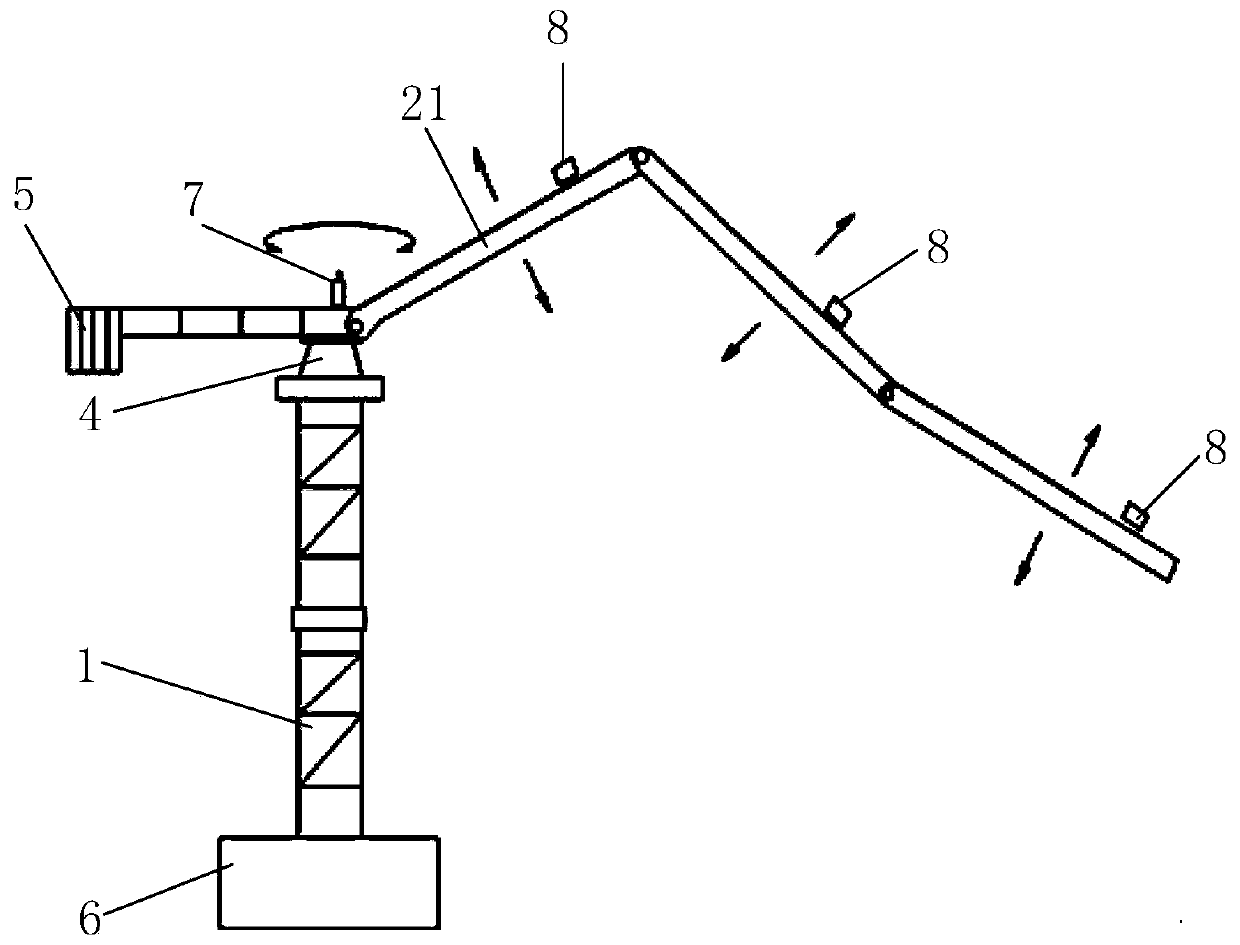

[0034] Such as Figure 1 to Figure 3 As shown, the concrete placing machine of this embodiment includes a tower body 1 , a machine arm 2 and a concrete delivery pipe 3 . The machine arm 2 is rotatably installed on the tower body 1 through the slewing support 4; the machine arm 2 is provided with a first detection assembly 7, and the first detection assembly 7 is used for detecting the horizontal rotation angle of the machine arm 2. The concrete conveying pipe 3 is installed on the machine arm 2, so that the concrete conveying pipe 3 can rotate horizontally with the arm 2 to realize the continuous rotary distribution of the concrete conveying pipe 3. The machine arm 2 includes a plurality of mutually hinged arm sections 21, through the combined change of the ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com