Control mechanism for rocker arm of multi-connecting-rod coal mining machine

A control mechanism and coal shearer technology, applied in the field of machinery, can solve problems such as interruption of coal mining work, poor working environment, and economic losses, and achieve the effects of increasing degrees of freedom, good shock absorption performance, and easy accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

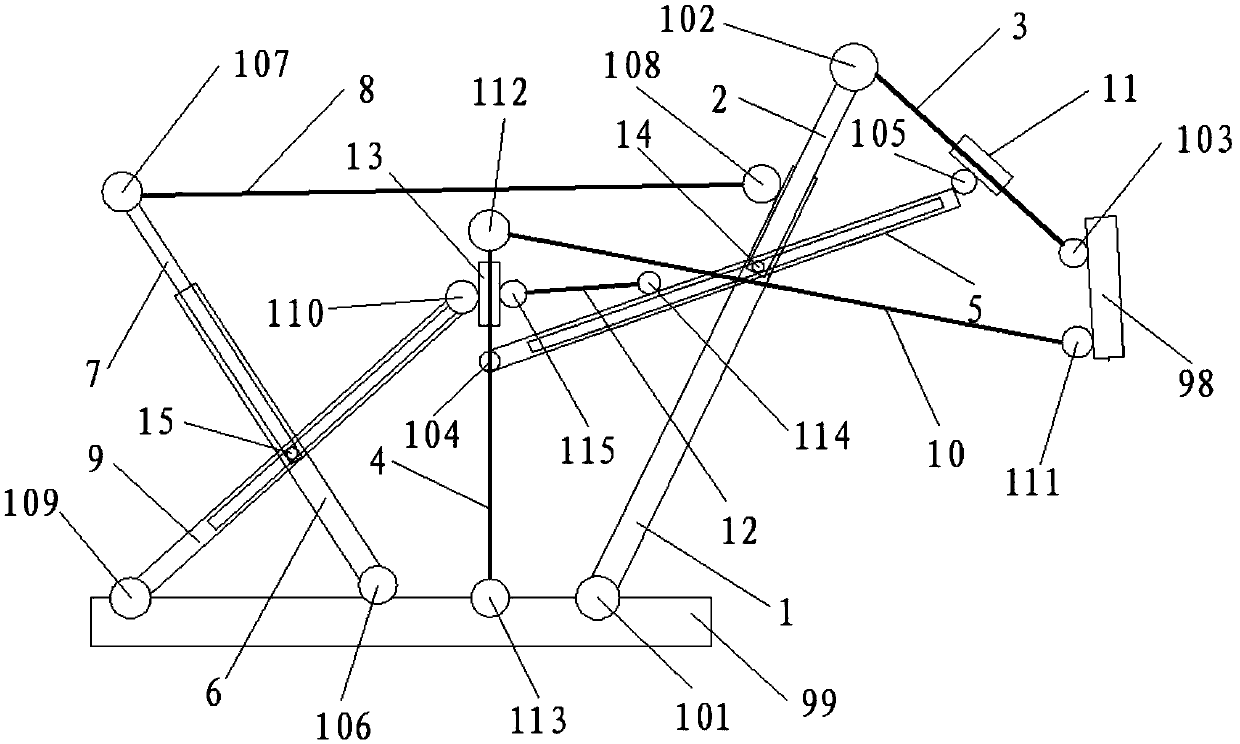

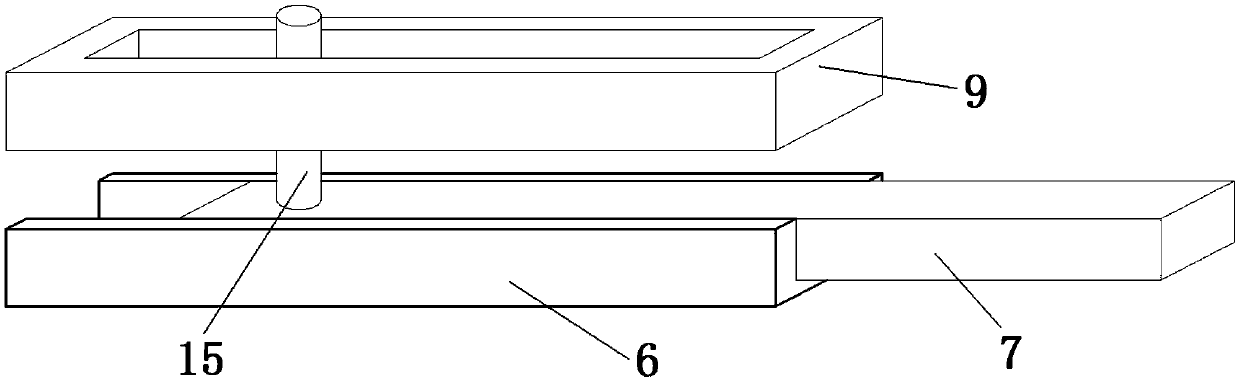

[0026] The control mechanism of the rocker arm of the multi-link shearer includes rod one 1, rod two 2, rod three 3, rod four 4, rod five 5, rod six 6, rod seven 7, rod eight 8, rod nine 9, rod 10. The first sliding sleeve 11, the third sliding sleeve 13, the first cylindrical pin 14, the second cylindrical pin 15, the actuator 98 and the frame 99,

[0027] Described rod nine 9 and rod five 5 are provided with axial chute,

[0028] One end of rod one 1 is connected to the frame 99 through rotating pair one 101, the other end of rod one 1 is connected to one end of rod two 2 through an axial movement pair, and the other end of rod two 2 is connected to one end of rod three 3 through rotating pair two 102, The other end of the rod three 3 is connected to the actuator 98 through the rotating pair three 103;

[0029] One end of rod four 4 is on the frame 99 through rotating pair thirteen 113, the other end of rod four 4 is connected to one end of rod ten 10 through rotating pair ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com