Optical unit, method of producing the same, and image pickup apparatus

An optical unit, image pickup element technology, applied in optical elements, chemical instruments and methods, optics, etc., can solve the problems of characteristic failure, film unevenness, pinholes, etc., and achieve the effect of easy precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Embodiments of the present technology will be described below with reference to the drawings.

[0049] It will be explained in the following order:

[0050] 1. The first structural example of the optical unit;

[0051] 2. The second structural example of the optical unit;

[0052] 3. The third construction example of the optical unit;

[0053] 4. A method of manufacturing an optical unit; and

[0054] 5. A configuration example of an image pickup device.

[0055]

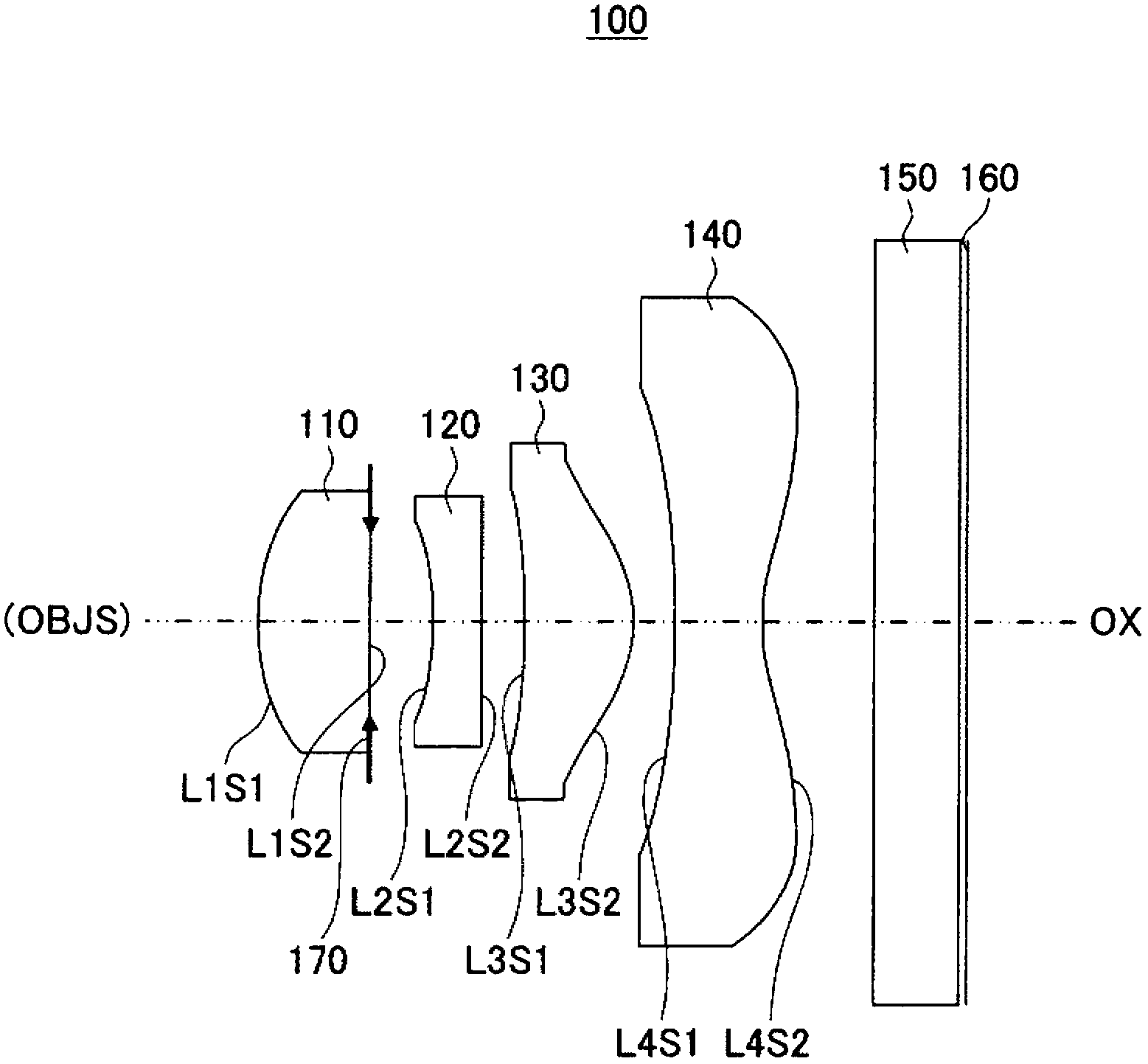

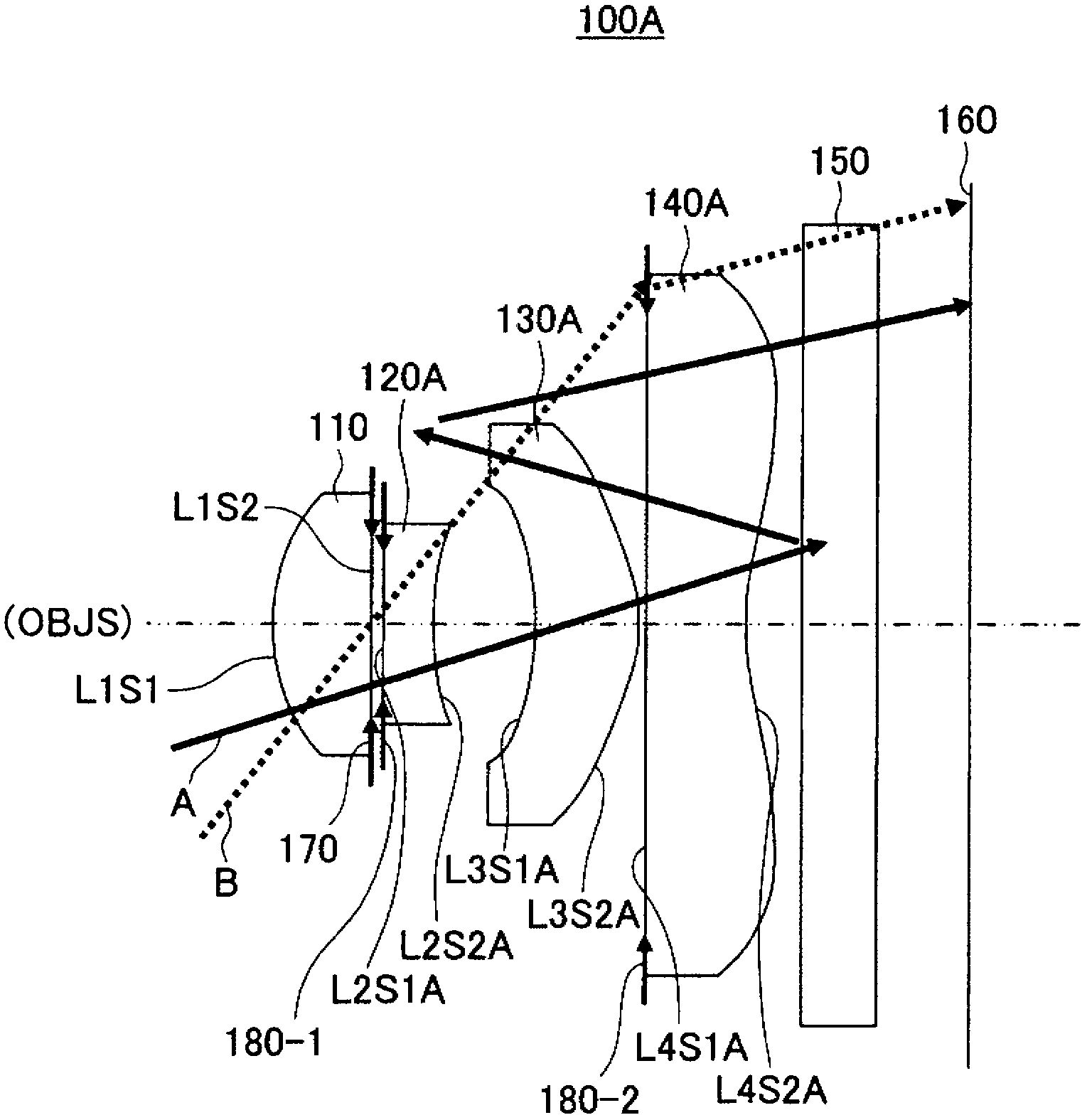

[0056] figure 1 is a diagram showing a first configuration example of the optical unit according to the present embodiment.

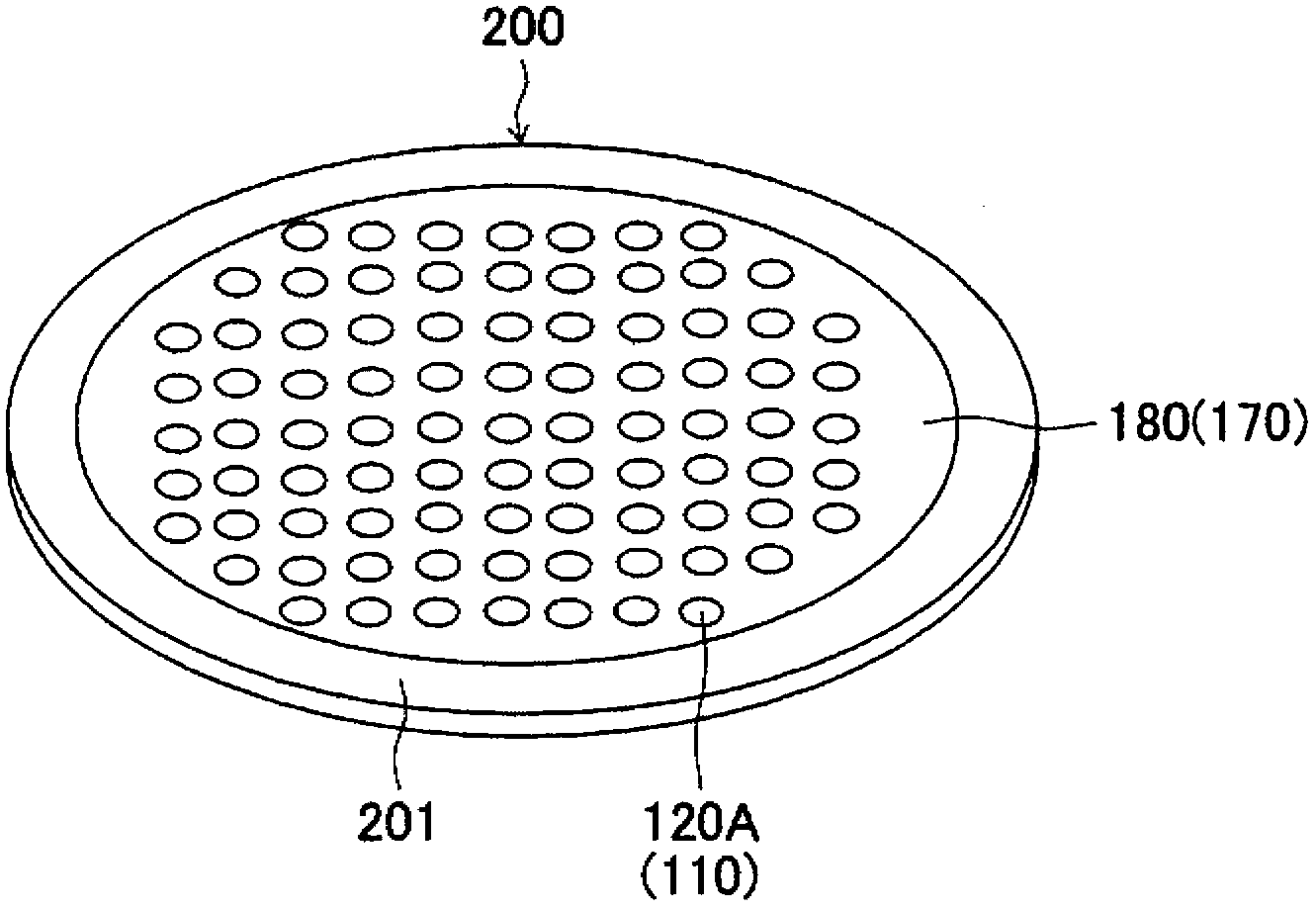

[0057] The optical unit 100 according to the present embodiment includes a plurality of (four in the present embodiment) lenses arranged along the optical path from the object side OBJS toward the image side.

[0058] In the optical unit 100 , the image-side surface or the object-side surface (the image-side surface in this embodiment) of one of the plurality of lenses is a waf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com