Hook face ceiling and installation method thereof

An installation method and ceiling technology, which can be used in building components, buildings, ceilings, etc., can solve the problems of lack of market competitiveness, unfavorable processing, and easy compression and deformation, so as to achieve market competitiveness, convenient overall installation, and limited shape. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

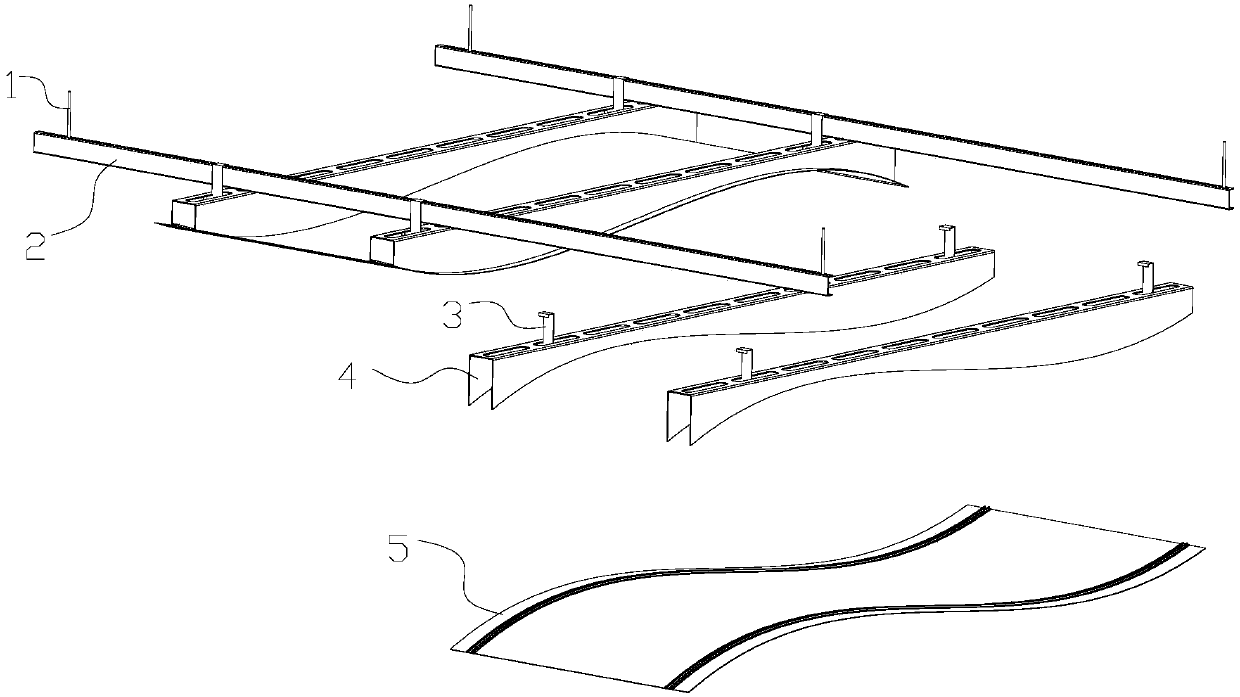

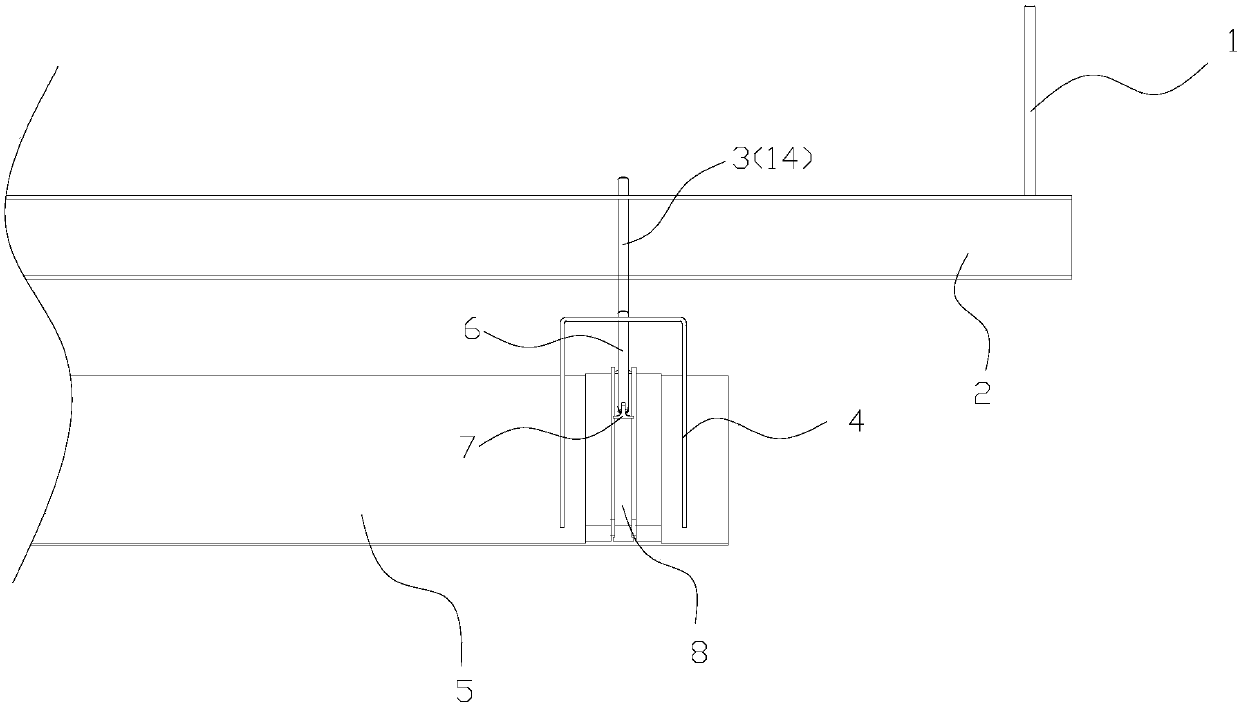

[0050] see Figure 1 to Figure 3 and Figure 7 , Embodiment 1 of the present invention provides a curved ceiling, including a hoisting assembly 1, an upper keel 2, a connecting member 3, a curved keel 4, an adjusting screw 6, and a flexible ceiling 5; the bottom of the bottom; the curved keel 4 is arranged along the horizontal and longitudinal extension, and its cross-section is "П" shape, wherein the bottom edge extends in a curve with ups and downs, and it is hoisted under the upper keel 2 through the connecting member 3; the flexible ceiling 5 follows the curve The bottom edge of the keel 4 is arranged, and the back is provided with a flexible tightening groove 8 extending along the curved keel 4. The tightening groove 8 is facing the center of the curved keel 4, and a plurality of slider components are sleeved in the tightening groove 8 7. The bottom end of the adjusting screw 6 is connected to the slider member 7, and the tightening groove 8 and the top plate of the curv...

Embodiment 2

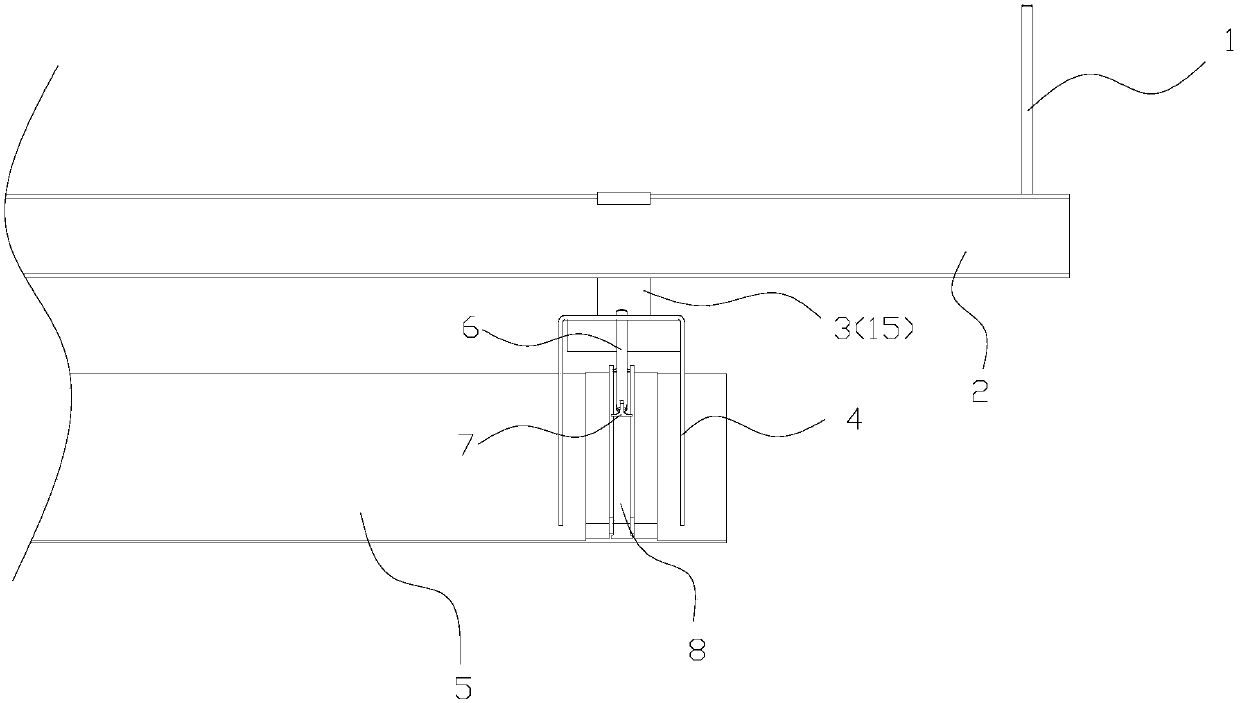

[0061] The only difference between this embodiment and the first embodiment is that the structural scheme of the connecting member 3 is different. see image 3 and Figure 5 , in this embodiment, as a preference, the connecting member 3 adopts the hanging code 15 structure. The top of the hanging code 15 is provided with a hook 10 matched with the cross section of the upper keel 2, the width of the hook 10 is smaller than the width of the slot 9, and the hook 10 is hooked on the upper keel 2; The supporting part 11 of side expansion, the width of supporting part 11 is greater than the width of long hole 9 and is equal to the distance of the inner side walls of the curved keel 4, and the supporting part 11 is placed inside the curved keel 4 and supports the top plate of the curved keel 4. As a further preference, the two sides of the supporting part 11 of the hanging code 15 are provided with stable ribs 12 bent toward the axial direction of the curved keel 4, and the outer s...

Embodiment 3

[0065] This embodiment provides a method for installing the curved ceiling in the above embodiments, including the following steps:

[0066] S01: Horizontally arrange and hoist the upper keel 2 on the roof of the building through the hoisting component 1;

[0067] S02: preset the connecting member 3 inside the curved keel 4, and make the top of the connecting member 3 pass through the long hole 9 on the top plate of the curved keel 4;

[0068] S03: Place the flexible ceiling 5 close to the bottom of the curved keel 4, move the slider member 7 to set a tightening point at the upper arc of the curved keel 4, and insert the top of the adjusting screw 6 from the long hole on the top surface of the curved ceiling 9 to pass through, tighten the nut and the adjusting screw 6 so that the flexible ceiling 5 fits completely on the arc of the bottom edge of the curved keel 4, forming a curved surface shape;

[0069] S04: Vertically arrange and hoist the curved keel 4 under the upper kee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com