Slope type positioning block adjusting mechanism

A positioning block and inclined surface technology, which is used in hand-held tools, workpiece clamping devices, manufacturing tools, etc., can solve the problems that the height of multiple positioning blocks cannot be controlled as the same plane, and the workpiece assembly is difficult to meet the requirements. The effect of good performance, easy precision and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

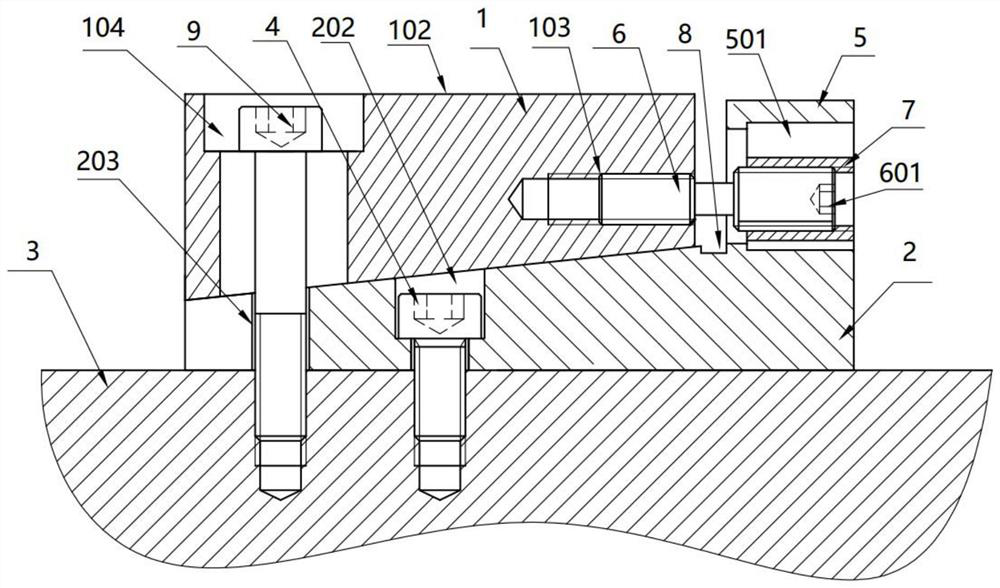

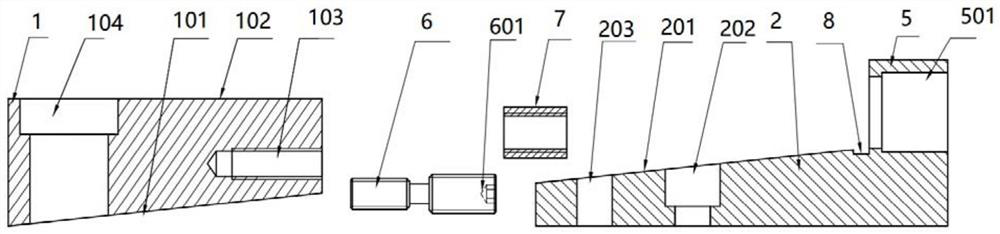

[0020] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following will be described in conjunction with the embodiments and accompanying drawings.

[0021] Such as figure 1 with figure 2 As shown, the present invention provides a slope-type adjustment positioning block mechanism, including an upper wedge block 1 and a lower wedge block 2 that cooperate with each other. The lower wedge block 2 is used to be fixedly connected with the positioning base 3 of the workpiece, and at least two mutual The matching upper wedge block 1 and lower wedge block 2 realize the support and positioning of the workpiece;

[0022] The bottom surface of the upper wedge block 1 is provided with a slope I101, and a part of the top surface of the lower wedge block 2 is provided with a slope II201 matching the slope of the slope I101. The horizontal angle of the slope I101 and the slope II201 is consistent, so that the upper wedge block 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com