Adjustable braking mechanism based on spiral piece

A brake mechanism and adjustable technology, applied in the field of automobile brakes, can solve the problems of brake pad failure, driver's life impact, brake pads can not be discharged in time, etc., to achieve the effect of improving service life, strengthening braking effect, and strengthening buffering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

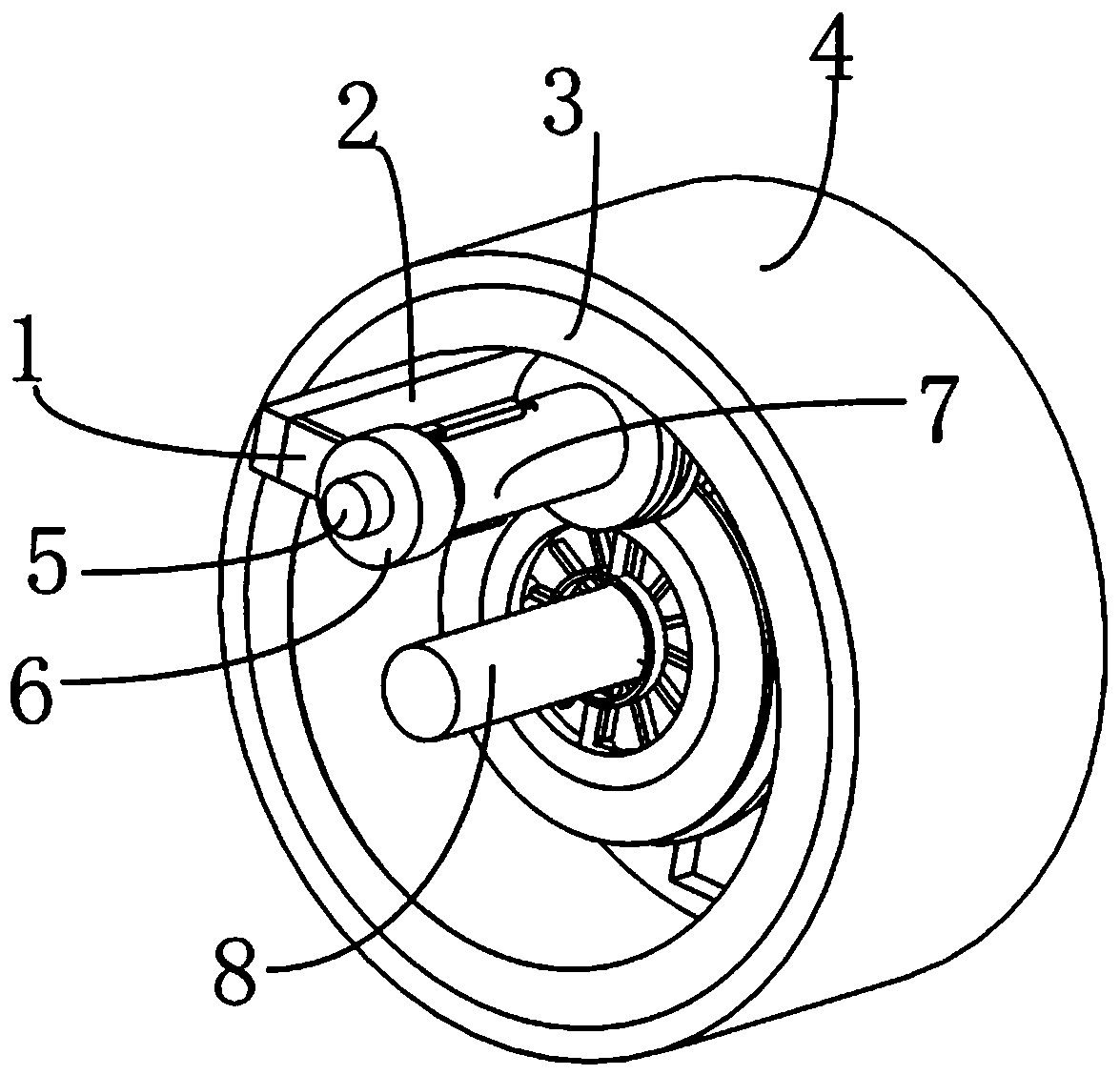

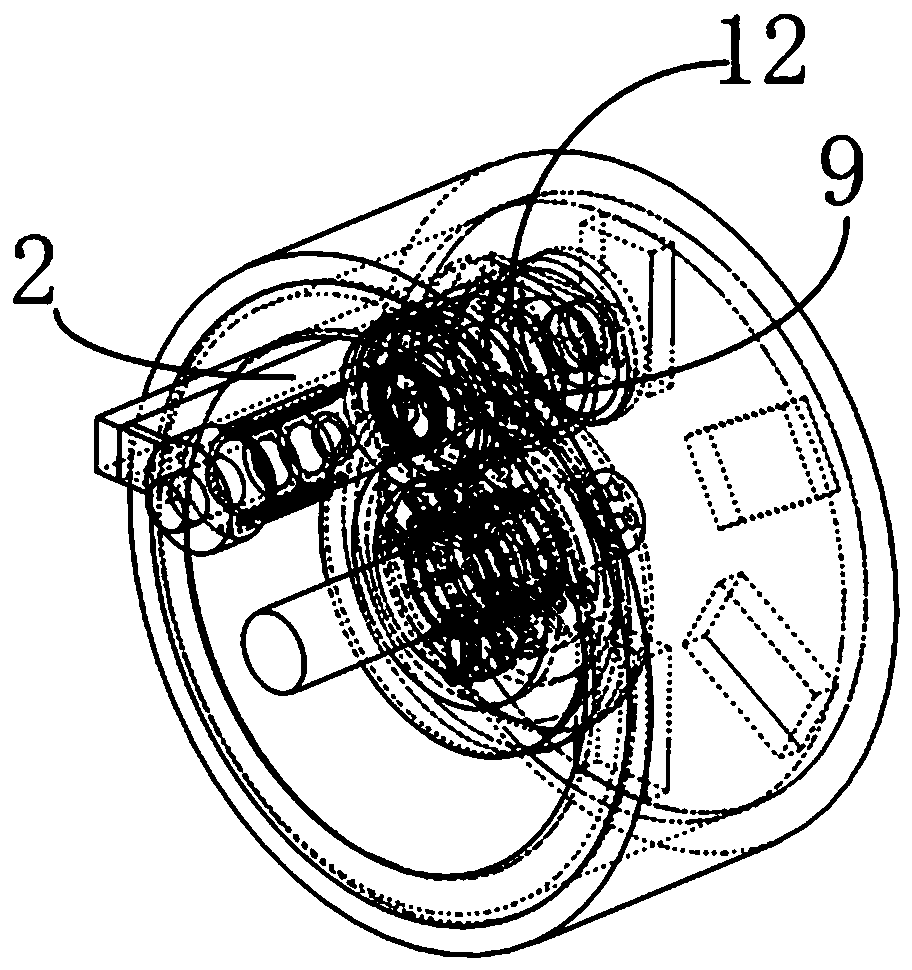

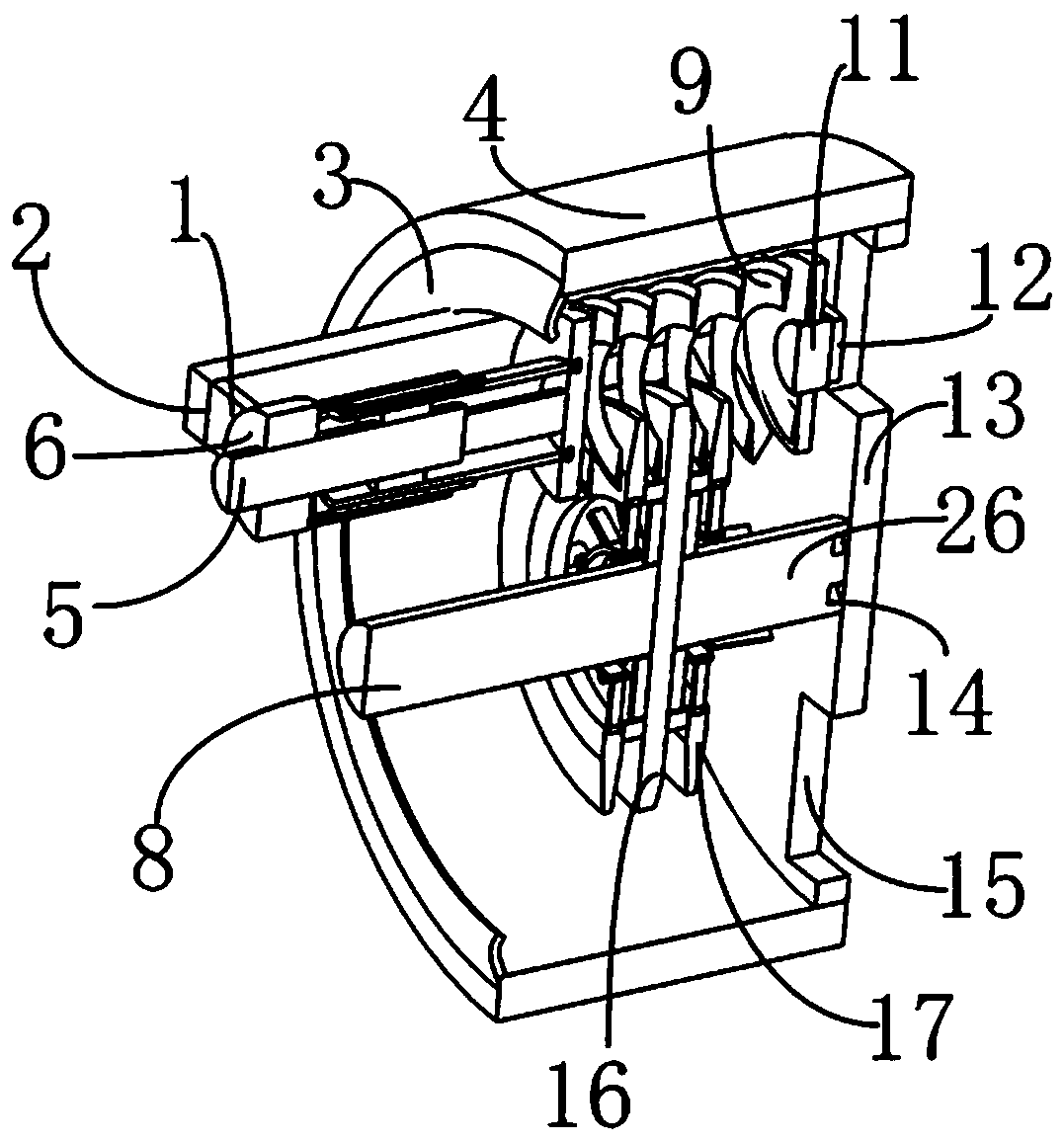

[0045] Specific embodiments: when people use the brake mechanism designed by the present invention; when the car is running; when the car needs to brake; control the brake shaft 5 to make it rotate; the rotation of the brake shaft 5 will drive the inner shaft 19 to rotate; the inner shaft 19 rotates Drive the inner disk 20 to rotate; the rotation of the inner disk 20 drives the spiral brake pad 9 to rotate; in the present invention, the spiral brake pad 9 is frictionally matched with the main brake pad 16 and the two auxiliary brake pads 17 respectively. Therefore, the rotation of the screw brake pad 9 and the friction generated between the rotating main brake pad 16 and the two auxiliary brake pads 17 can buffer the rotation of the drive shaft 8; thereby achieving a braking effect. Simultaneously during the rotation of the brake rotating shaft 5; the rotation of the brake rotating shaft 5 will drive the threaded ring 18 to rotate; Move, that is, the threaded ring 18 will not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com