Intelligent natural gas combustion furnace capable of avoiding backfire phenomenon

A natural gas and combustion furnace technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve the problems of difficult to guarantee the working performance of the combustion furnace, safety accidents, tempering, etc., to avoid the phenomenon of tempering, safe use Guarantee and ensure the effect of normal combustion treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

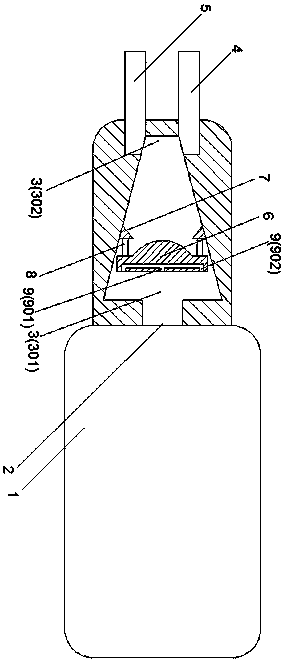

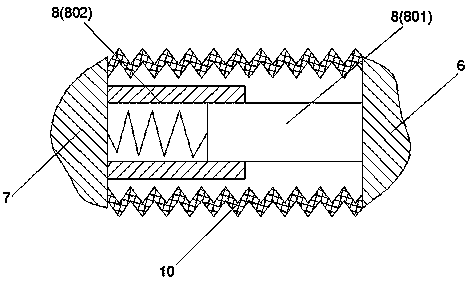

[0015] Such as figure 1 The intelligent natural gas burner that can avoid backfire phenomenon includes a burner body 1; an air inlet port 2 is arranged on the burner body 1, and the air inlet port 2 is connected with a natural gas mixing chamber 3 , the natural gas mixing chamber 3 is respectively connected with a natural gas inlet pipe 4 and an atmospheric air inlet pipe 5; The end portions 301 are opposite to each other at the second end portion 302, the inner diameter of the natural gas mixing chamber 3 gradually decreases in the direction in which the first end portion 301 extends toward the second end portion 302; the first end portion of the natural gas mixing chamber 3 301 is provided with a pipe diameter control device, which includes a control end plate 6 extending radially along the natural gas mixing chamber, and a support end plate 7 arranged on the inner wall of the natural gas mixing chamber 3. The support end plate 7 adopts an annular structure, the control end...

Embodiment 2

[0018] As an improvement of the present invention, a plurality of spoiler pipes 9 are arranged on the end surface of the control end plate 6 relative to the first end 301 of the natural gas mixing chamber 3, and each spoiler pipe 9 includes The first end portion 901 that controls the position of the axial center of the end plate 6 , and the second end portion 902 that extends to the side portion of the control end plate 6 along the radial direction of the control end plate 6 .

[0019] The remaining features and advantages of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0021] As an improvement of the present invention, the end surface of the control end plate 6 relative to the second end 301 of the natural gas mixing chamber 3 adopts a curved surface structure bent toward the second end 302; The end surface of the second end portion 302 of the mixing chamber 3 extends obliquely downward.

[0022] The remaining features and advantages of this embodiment are the same as those of Embodiment 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap