Electric heating type air humidification control method and system

A technology of air humidification and control method, which is applied in the direction of control input related to air characteristics, space heating and ventilation control input, heating mode, etc. It can solve the problems of air humidity error and waste of electric energy, and achieve accurate and error-free measurement values. Energy saving and cost saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

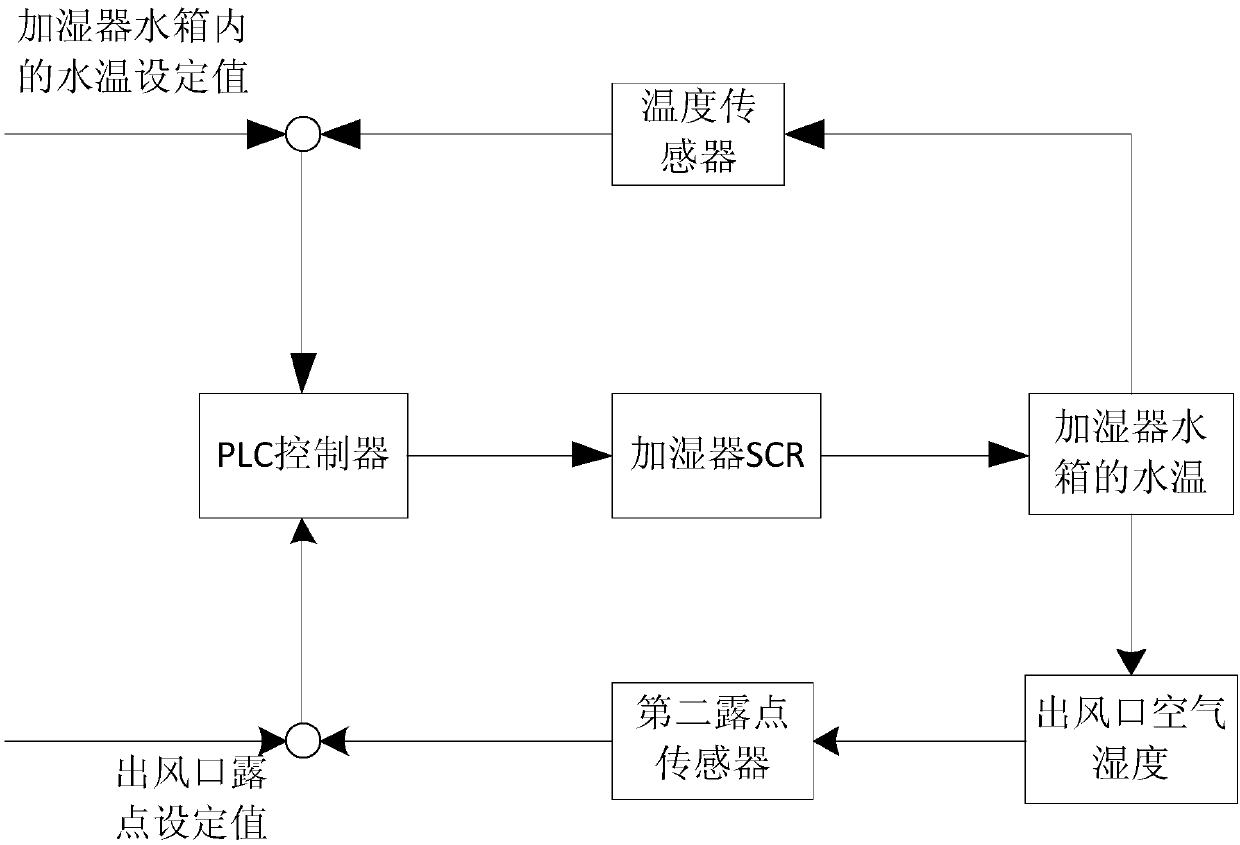

[0032] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0033] This embodiment discloses an electric heating air humidification system, including: a humidifier, a first dew point sensor and a second dew point sensor. The humidifier is electrically connected to the PLC controller, and the humidifier water tank is provided with a temperature sensor electrically connected to the PLC controller. The temperature sensor is used to detect the water temperature in the water tank and feeds back to the PLC controller. The first dew point sensor is installed at the air inlet of the air supply equipment and is electrically connected to the PLC controller. The first dew point sensor is used to detect the air dew point at the air inlet of the air supply equipment and feeds back to the PLC controller.

[0034] According to the comparison between the measured dew point ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com