Touch panel vibration feedback apparatus

A technology of touch panel and vibration feedback, which is applied in the directions of instruments, electrical digital data processing, user/computer interaction input/output, etc. It can solve the problems of increasing cost, unfavorable promotion, occupying panel space, etc., so as to reduce the number of uses, The effect of reducing product volume and reducing product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

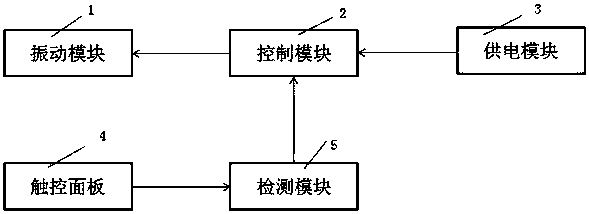

[0024] This embodiment provides a vibration feedback device for a touch panel, including a touch panel 4, a detection module 5, several vibration modules 1, several control modules 2, and a power supply module 3; the detection module 5 is arranged below the touch panel 4, and the detection module 5 is used to receive the touch signal and transmit it to the control module 2 . Each control module 2 is respectively coupled between the detection module 5 and each vibration module 1, and adjusts the vibration characteristics of the corresponding vibration module 1 according to the touch signal. The vibration module 1 can be a vibration motor or a piezoelectric actuator, which is used in this embodiment. The vibration module 1 is a vibration motor. The power supply module 3 is used for providing working electric energy to the control module 2 and the vibration module 1 . Wherein, each vibration module 1 can be provided with several vibration levels, and the touch panel 4 is provide...

Embodiment 2

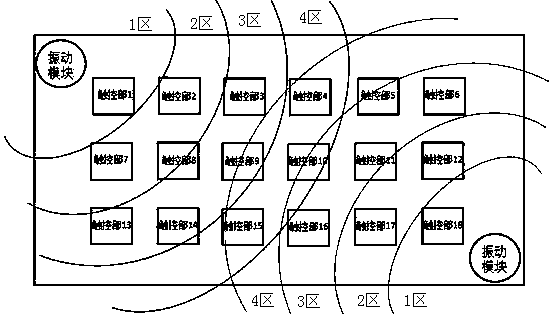

[0026] This embodiment is similar to Embodiment 1. Further, the touch panel 4 may also be provided with several touch parts, and each touch part is used for the customer to input touch actions. In this embodiment, the touch panel 4 is provided with 18 touch parts, and the 18 touch parts are distributed in the corresponding area according to the linear length of each vibration module 1, and at least one specific vibration module 1 The vibration levels are matched, and the vibration intensities generated by the vibration modules 1 at the same position are superimposed on each other, and the superimposed vibration intensities make the vibration effects generated by the touch parts the same, and the hand feeling is uniform.

Embodiment 3

[0028] A control method for vibration feedback of a touch panel, based on the above-mentioned vibration feedback device for a touch panel, comprising the following steps:

[0029] S1. Presetting each of the vibration modules 1 to several vibration levels, the vibration levels are proportional to the straight line length from the vibration module 1;

[0030] S2. Dividing the touch panel 4 into several touch areas;

[0031] S3. According to the straight-line lengths between different touch areas and each of the vibration modules 1, match the touch areas with the vibration levels of each vibration module 1, and the vibration effects of each of the vibration modules 1 in the same touch area are superimposed on each other. ;

[0032] S4. The detection module 5 receives the input touch signal, and transmits the touch signal to the corresponding control module 2 according to the matching result of the touch signal and the vibration level signal;

[0033] S5. The control module 2 ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com