Method for manufacturing stretch flange molded component

A technology for forming parts and stretch flanges, which is applied in vehicle parts, transportation and packaging, etc., can solve the problems of easy cracking and wrinkles, and achieve the effect of inhibiting the cracking of stretch flanges.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

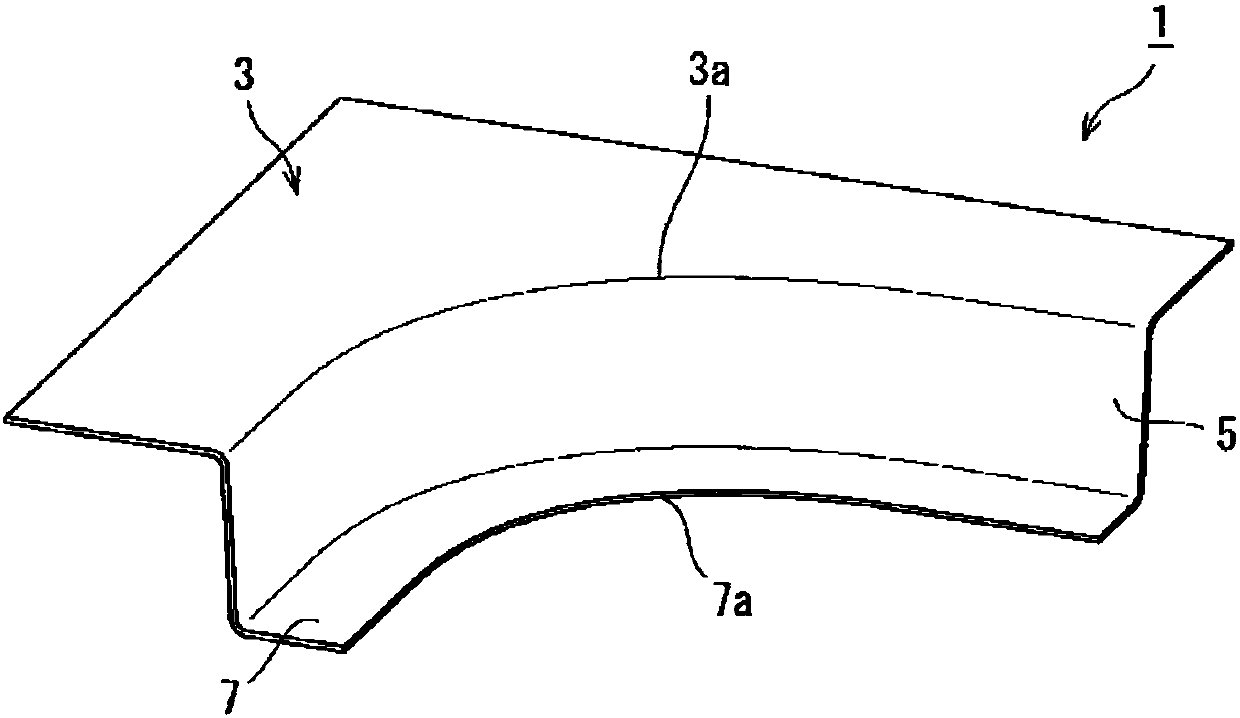

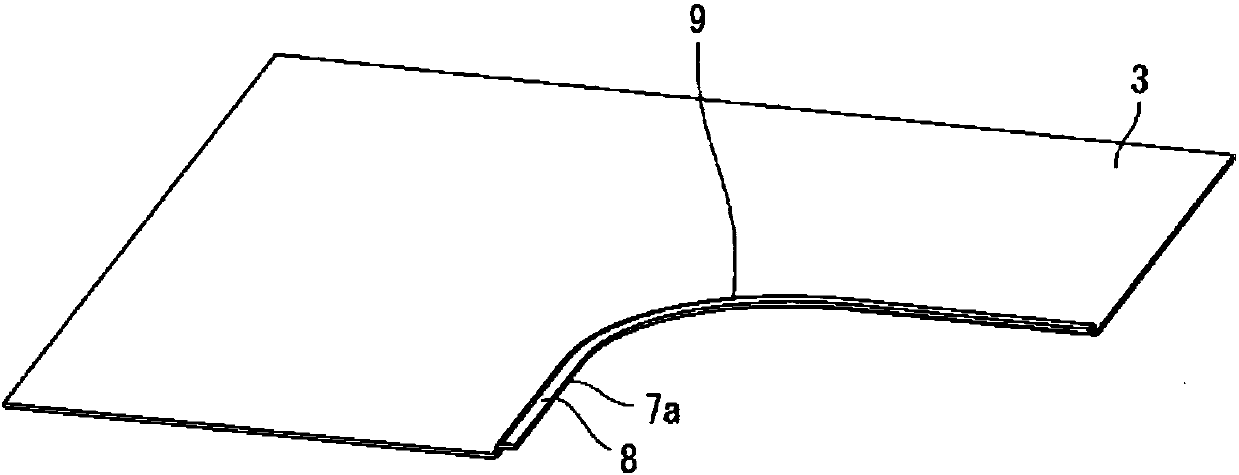

[0145] Furthermore, as Example 1, the presence or absence of the stepped portion 8 was evaluated at the flange portion forming position.

[0146]In Example 1, regarding the above-mentioned two members, it was evaluated whether there was a stepped portion 8 along the second concave outer peripheral edge portion 7a at the position where the flange portion 7 was formed, and whether there was no difference at the position where the flange portion 7 was formed. Whether stretch flange cracking occurs along the stepped portion 8 of the second concave outer peripheral edge portion 7a.

[0147] The method of determining the ridgeline 9 of the stepped portion 8 is determined by the above-mentioned first determination method and second determination method.

[0148] Furthermore, in the case of the stepped portion 8 having the stepped portion 8, the first ridgeline 9A is set at a straight line perpendicular to the central line 23 at a distance of 30 mm from the second concave outer periph...

Embodiment 2

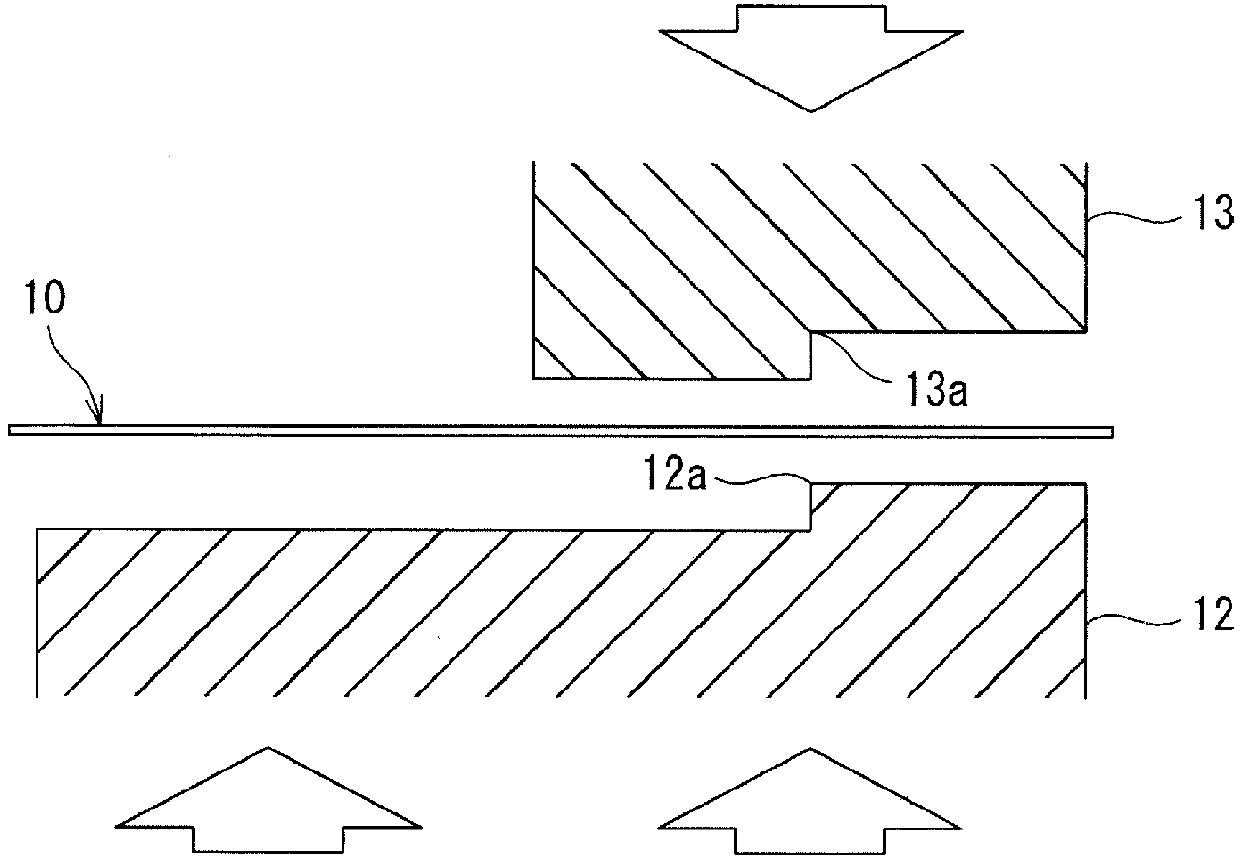

[0155] As Example 2, the position of the first ridgeline 9A was evaluated.

[0156] In Example 2, regarding the above-mentioned two members as objects, in the case of having the stepped portion 8, according to the distance from the concave outer peripheral portion when the first ridgeline 9A is set on the stepped portion 8, whether The occurrence of tensile flange cracking was evaluated.

[0157] At this time, the second ridgeline 9B coincides with the reference line 22, and the step height is uniformly 5 mm.

[0158] Table 2 shows the evaluation results.

[0159] [Table 2]

[0160]

[0161] From Table 2, it is estimated that stretch flange cracking occurs when the set position of the first ridgeline 9A formed in the second step deviates from the second concave outer peripheral portion 7a by 20 mm to 50 mm.

[0162] It is considered that when the first ridgeline 9A is set to be 20 mm or less, since the stepped portion 8 is formed near the second concave outer peripheral ...

Embodiment 3

[0164] As Example 3, the effect by the position of the second ridgeline 9B was evaluated.

[0165] In Example 3, regarding the above-mentioned two members as objects, in the case of having the stepped portion 8, it was evaluated whether or not a pull occurred based on the amount by which the position of the second ridgeline 9B of the step was shifted to the left and right from the reference line 22. Flange cracked.

[0166] At this time, the position of the first ridgeline 9A was set to be 30 mm away from the second concave outer peripheral portion 7 a, and the step height was uniformly set to 5 mm.

[0167] Table 3 shows the evaluation results.

[0168] [table 3]

[0169]

[0170] As can be seen from Table 3, it was evaluated that stretch flange cracking occurred when the second ridgeline 9B was deviated from the reference line 22 by more than ±5 mm by the molding in the second step.

[0171] This can be presumed to be: when the inward deviation from the reference line ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com