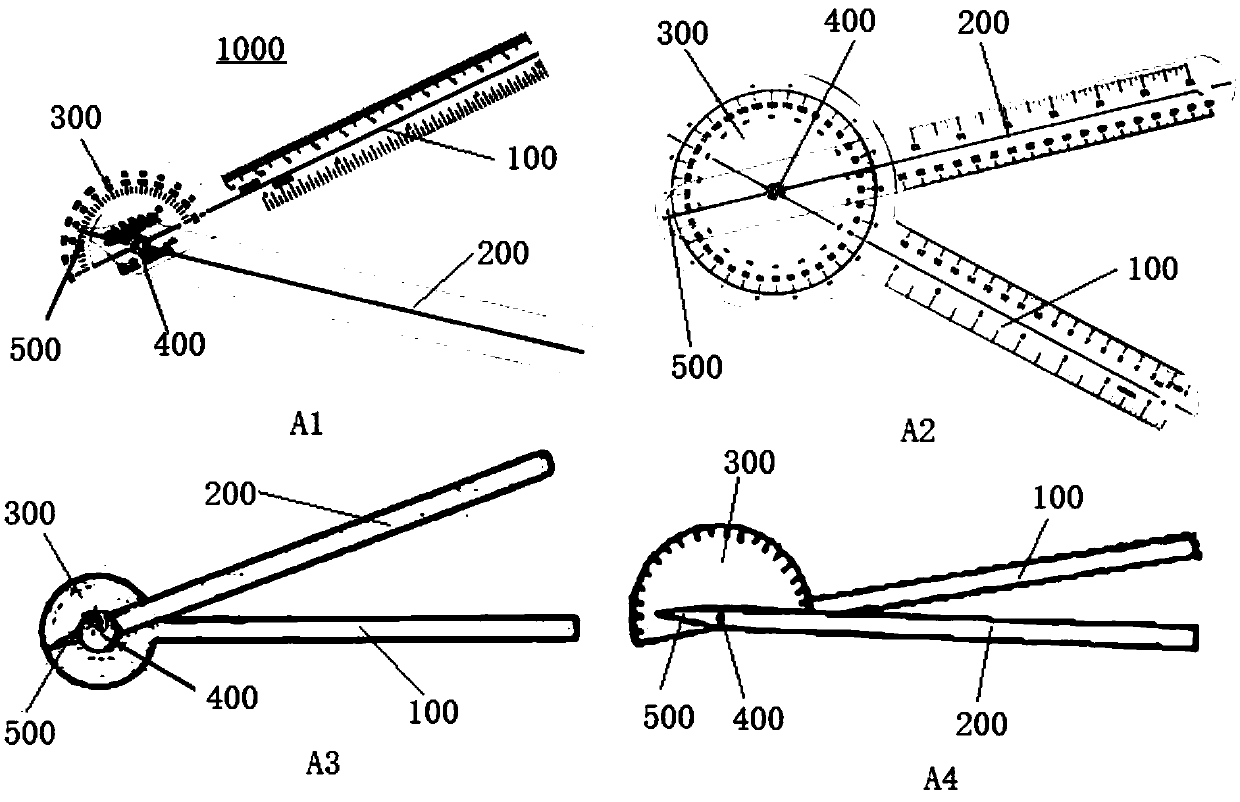

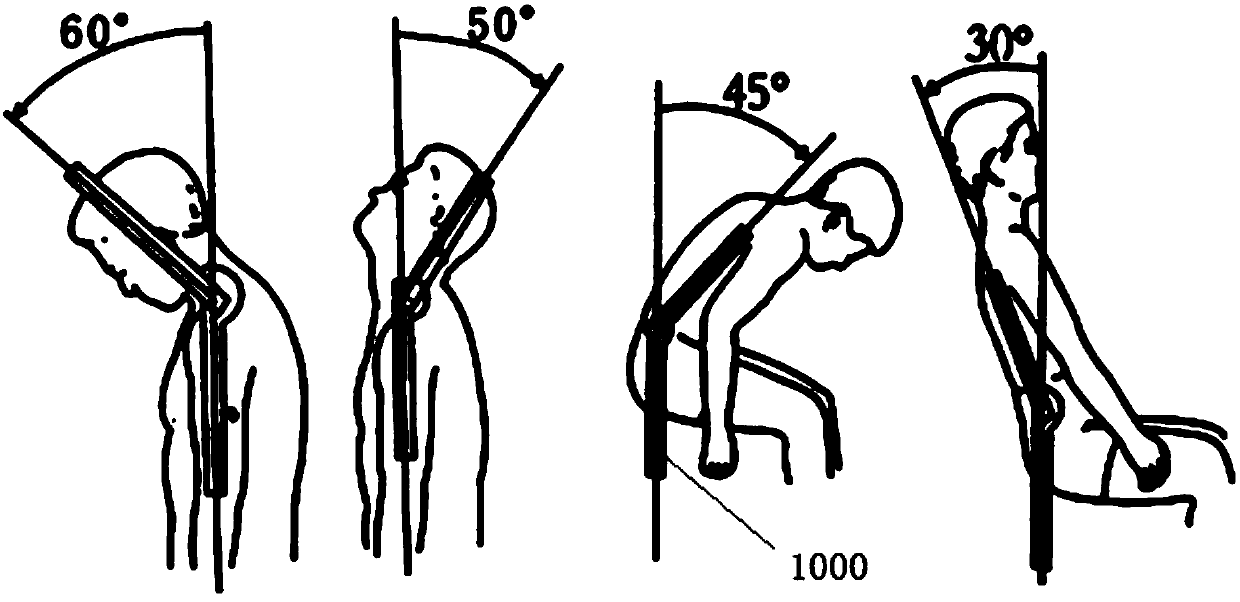

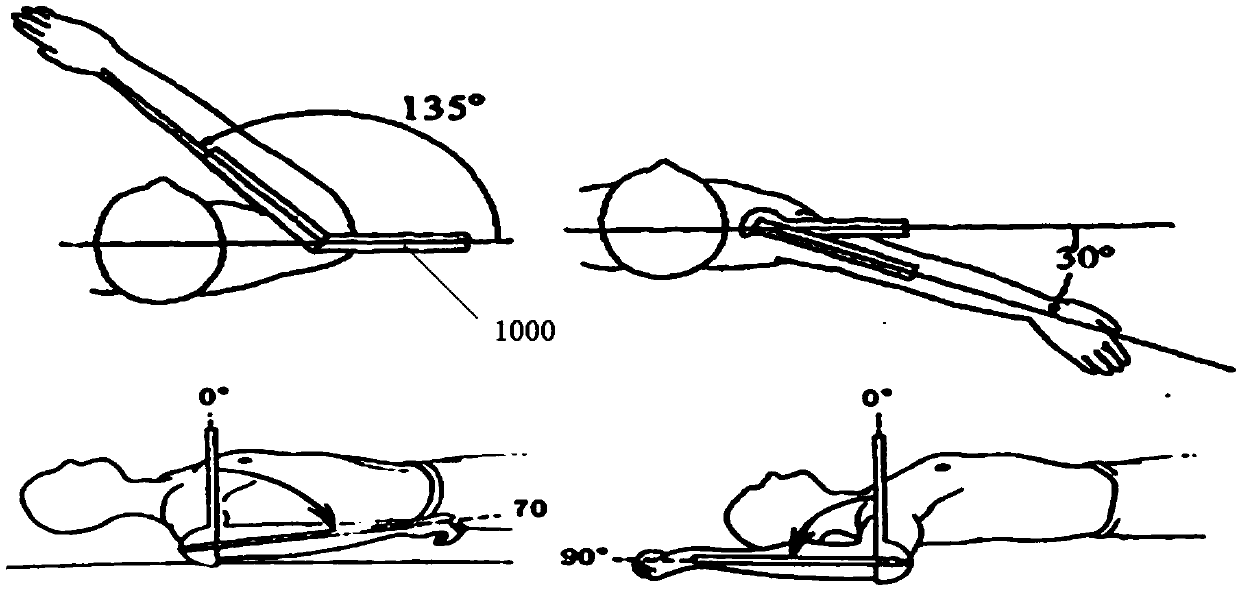

Human multidimensional joint motion range measuring instrument and operating principle thereof

A technology for measuring tables and activity, applied in the field of measuring tables, can solve problems such as difficult alignment, unsatisfactory multi-dimensional motion joint measurement, poor data consistency, etc., to ensure stability and accuracy, simple structure, and high practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] See Figure 7 to Figure 10 As shown, a human body multidimensional joint range of motion measurement meter 10 of an embodiment is shown, which includes a measurement meter housing, and the measurement meter housing includes a glass 12, a dial 13, a bottom shell 14 and a side shell 11, and the glass 12 1. The dial 13 and the bottom case 14 are sequentially installed in the side case 11, the driving part 20 is between the bottom case 14 and the dial 13, and the pointer part 30 is between the glass 12 and the dial 13;

[0046] The driving part 20 is installed on the back of the dial 13. The driving part 20 includes a gravity hammer 21, a driving wheel 22, a first driven wheel 23, a second driven wheel 24, a damping wheel 25 and a gravity hammer driving wheel 26. The driving wheel 22 is installed on the dial 13 and the axis 221 of the driving wheel 22 coincides with the center of circle of the dial 13, the driving wheel 22 meshes with the first driven wheel 23, the first dr...

Embodiment 2

[0087] In this embodiment, the basic structure of the measuring meter is the same as that in Embodiment 1, the only difference is that in this embodiment, only two gear meshing structures are used to achieve the same technical effect as in Embodiment 1. Specifically, in this embodiment, what is installed on the back of the dial 13 is a driving wheel 42, a driven wheel 43, a bracket 44 and a gravity hammer 41. The gravity hammer 41 is connected with the driven wheel 43 through the bracket 44, and the driven wheel 43 is engaged with the driving wheel 42. When the gravity hammer 41 is facing such as Figure 16 When moving in the direction of middle B, the driven wheel 43 rotates counterclockwise, and the driving wheel 42 meshed with the driven wheel 43 rotates clockwise, that is, the measuring pointer connected to the driving wheel 42 rotates to the right, and the direction of the measuring pointer is consistent with the direction of the gravity hammer 41 unanimous. In this embo...

Embodiment 3

[0094] like Figure 17 As shown, in the present embodiment, all the gear mechanisms of the first embodiment are canceled for the measuring table. This alternative solution cancels the memory pointer mechanism of Embodiment 1. The scheme of this embodiment retains the left and right measurement mode of Embodiment 1, and improves it to a left and right 0°-360° full-circle rotation mode, and adds left and right 180°-360° numerical labels. The principle of the gravity hammer in Embodiment 1 is retained, replaced by the integration of the pointer rod, the pointer rod passing through the horizontal bar, the pointer rod behind the disk, and the weight hammer, and the middle part of the pointer rod (the pointer rod passing through the Pan crossbar) passes through the table center hollow tube; the pointer rod, the cross-pan cross bar, and the pointer rod behind the disc are respectively opposite vertical and parallel on a plane. The rear end of the pointer rod is connected with a hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com