Lifting device for oxygen acetylene cylinder detection

A lifting device, oxygen acetylene technology, applied in the direction of lifting device, lifting frame, etc., can solve the problems of poor stability, inability to guarantee safety performance, easy to swing back and forth, and achieve high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

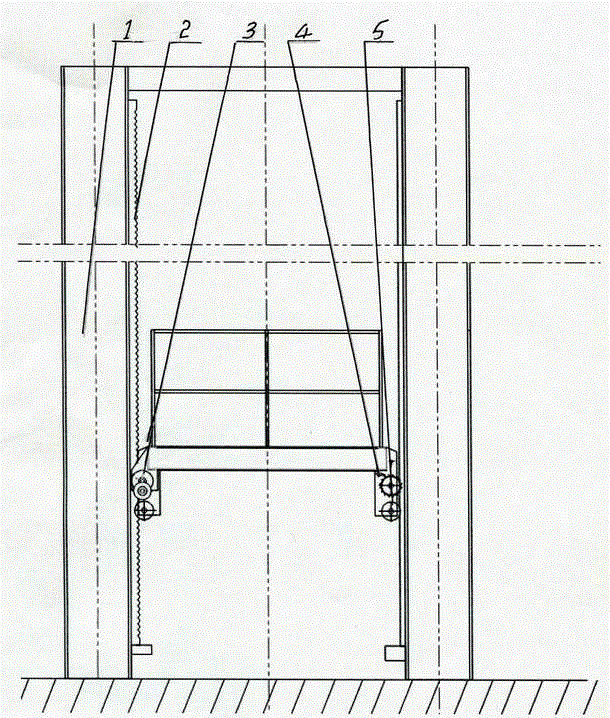

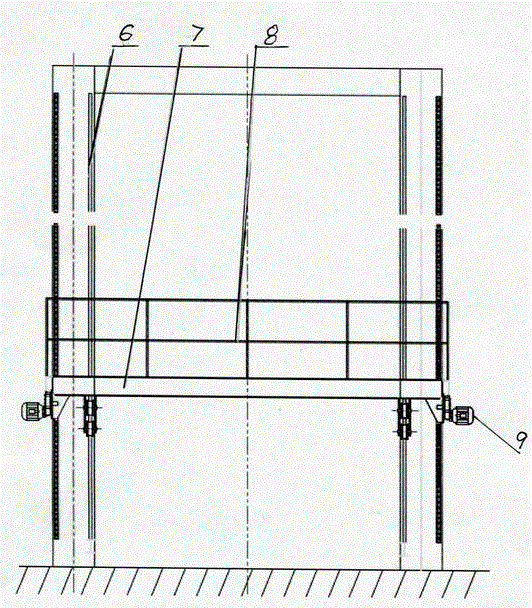

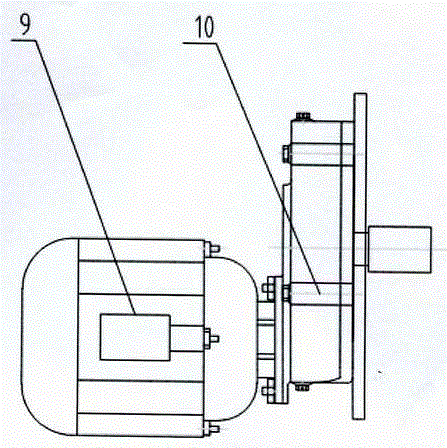

[0008] Embodiments are described in detail in conjunction with the above accompanying drawings, as figure 1 , Image 6 with Figure 7 As shown, the frame 1 is composed of four columns and beams built on them and fixed to the foundation ground with embedded bolts. Further, the columns are made of four H-shaped steel flange plates, and vertically along the inner surface of each column. A rack 2 is welded, and a track 6 is welded on the opposite side of the rack. The lifting platform 7 is arranged in the working area of the frame. The four corners below the lifting platform are equipped with guide wheels 5 through guide wheel frames. The guide wheels can be Run freely in the track, the described guide wheel frame is equipped with a ratchet 4, the ratchet is equipped with a pawl 4-1, the surroundings of the lifting platform are surrounded by railings 8 to form a space for placing acetylene bottles, and the described guide wheels are double rim (eg Figure 4 As shown), to prev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com