Assembling tool for electromagnetic switch of starter

An electromagnetic switch and assembly tooling technology, applied in the direction of electric switches, circuits, metal processing, etc., can solve the problems of difficult to guarantee the position accuracy of the guide sleeve, servo gun torque alarm, long guide sleeve length, etc., to improve its own manufacturing accuracy, gun High accuracy of head position and effect of improving tool life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

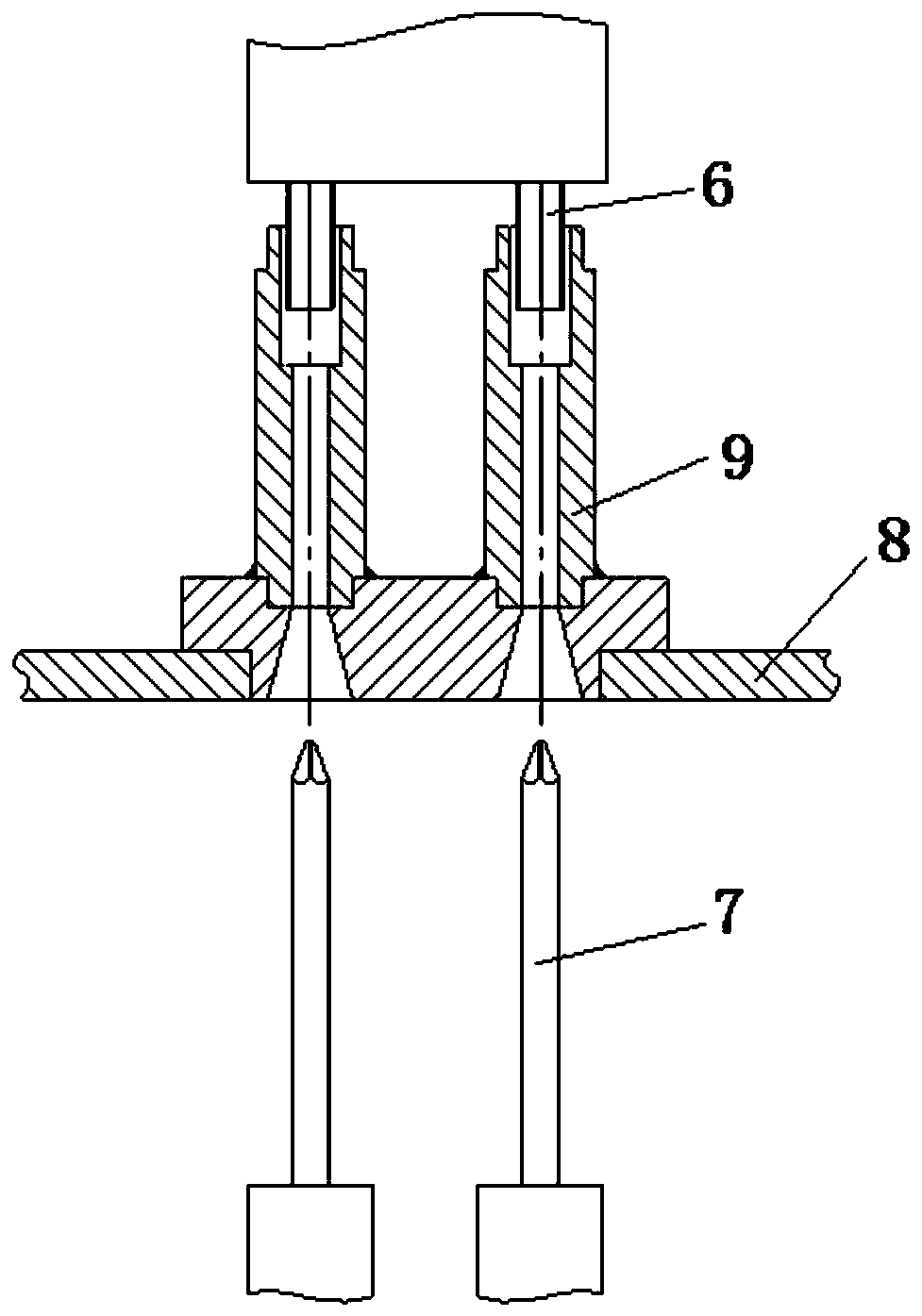

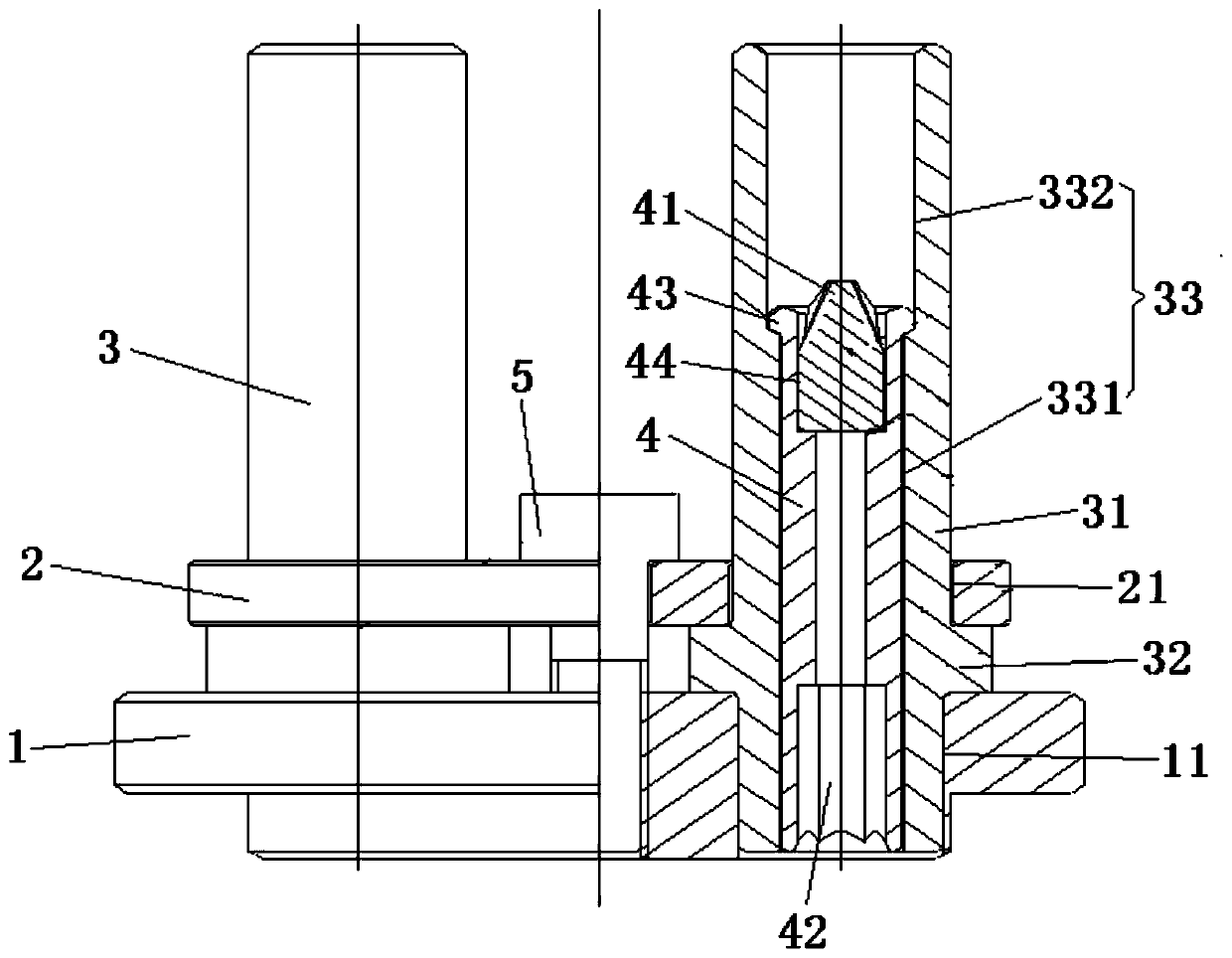

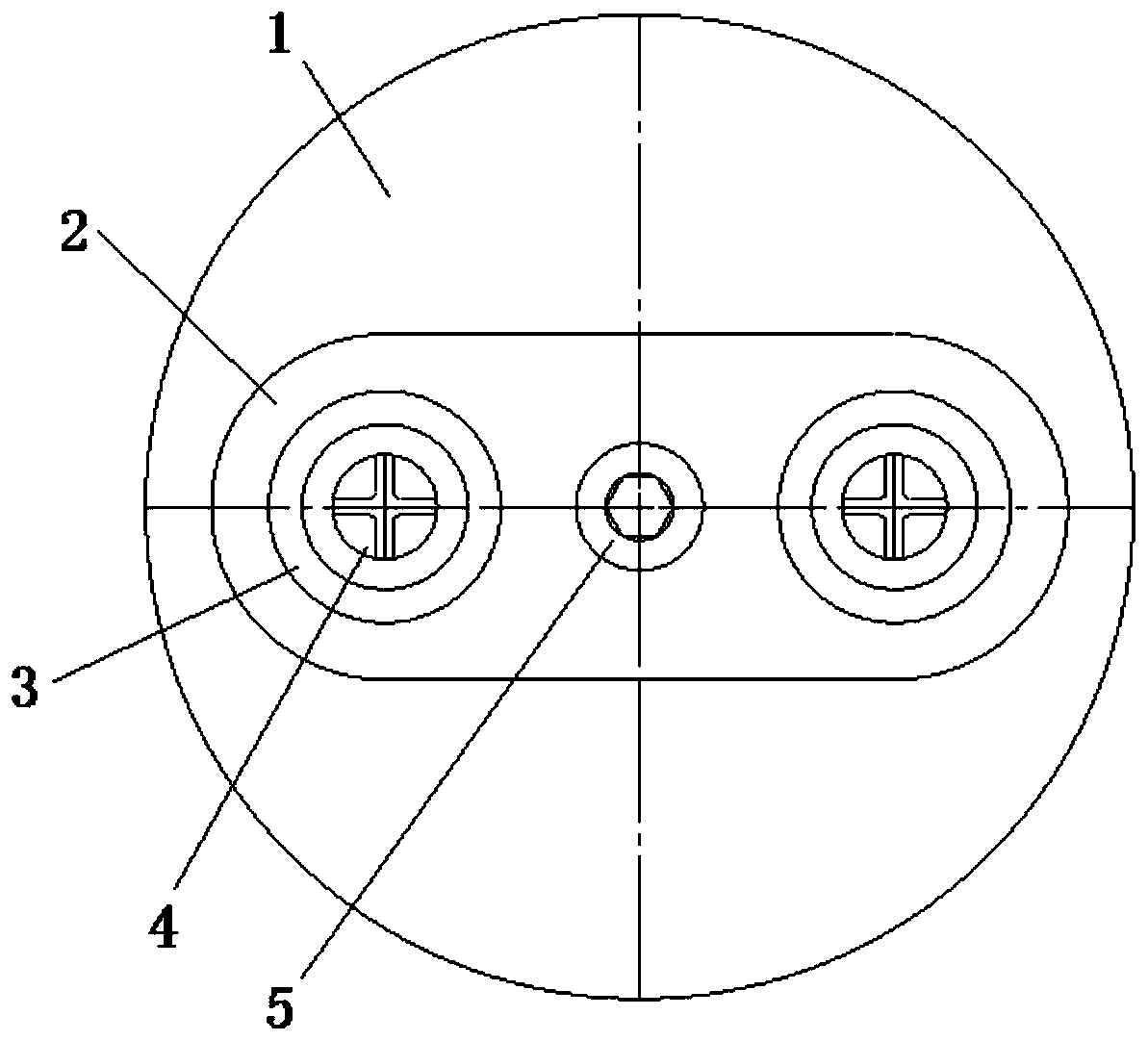

[0019] Such as figure 2 and image 3 As shown, the starter electromagnetic switch assembly tooling includes a tooling seat 1, a pressing plate 2, a guide sleeve 3 and an assembly column 4; the tooling seat 1 has two parallel guide sleeve holes 11; the guide sleeve 3 and the guide sleeve hole 11 One-to-one corresponding arrangement, the guide sleeve 3 includes the guide sleeve main body 31 and the connecting flange 32, the rear end of the guide sleeve main body 31 is inserted into the guide sleeve hole 11 and cooperates with the guide sleeve hole 11, the connecting flange 32 abuts on the tooling seat 1, The guide sleeve 3 is provided with a guide hole 33; the pressure plate 2 is provided with two pressure plate holes 21, the pressure plate 2 is set on the two guide sleeve main bodies 31 through the two pressure plate holes 21, the pressure pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com