Efficient residue-free solid-liquid reaction device for chemical engineering

A solid-liquid reaction, no residue technology, applied in chemical/physical/physicochemical fixed reactors, feeding devices, lighting devices, etc., can solve the problems of affecting the quality of reactants, low reaction efficiency, easy to block pipelines, etc. Achieve the effect of simple structure, increase reaction rate and increase reaction contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

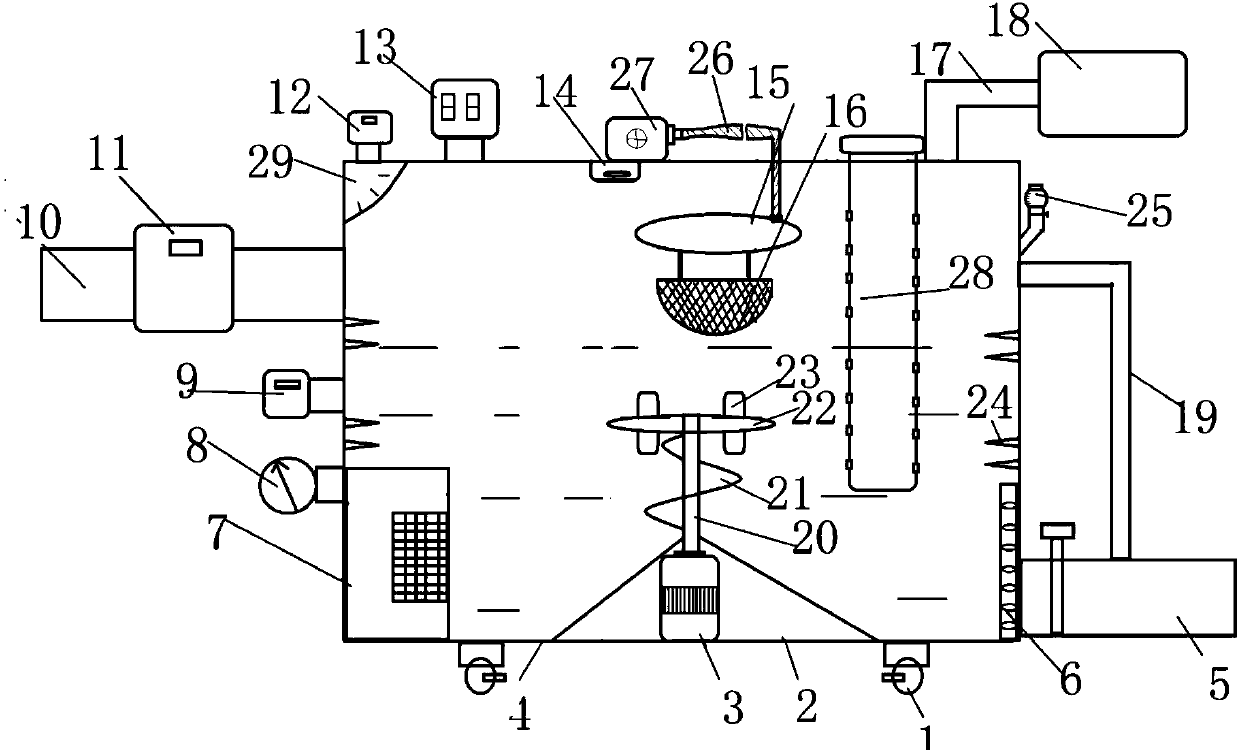

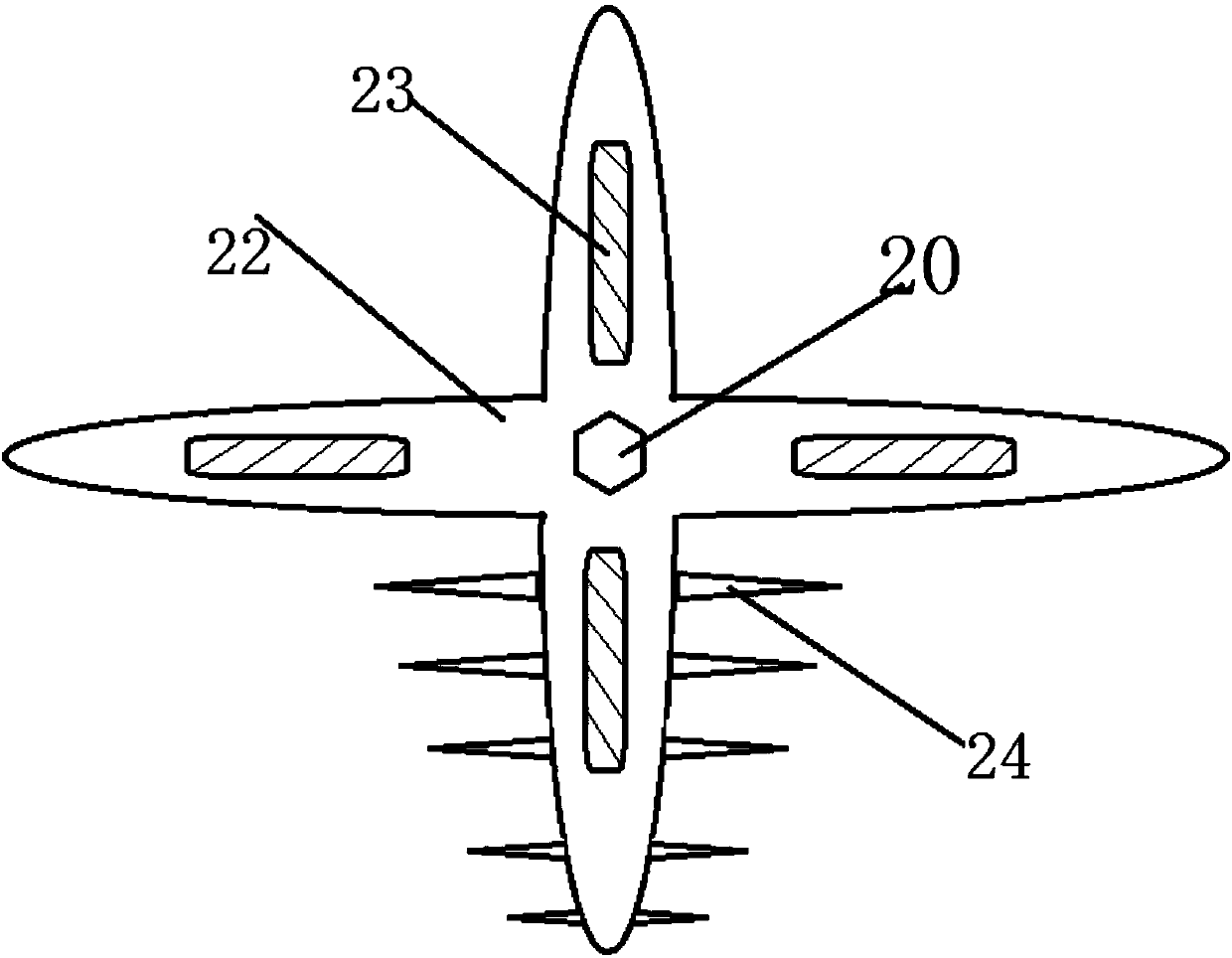

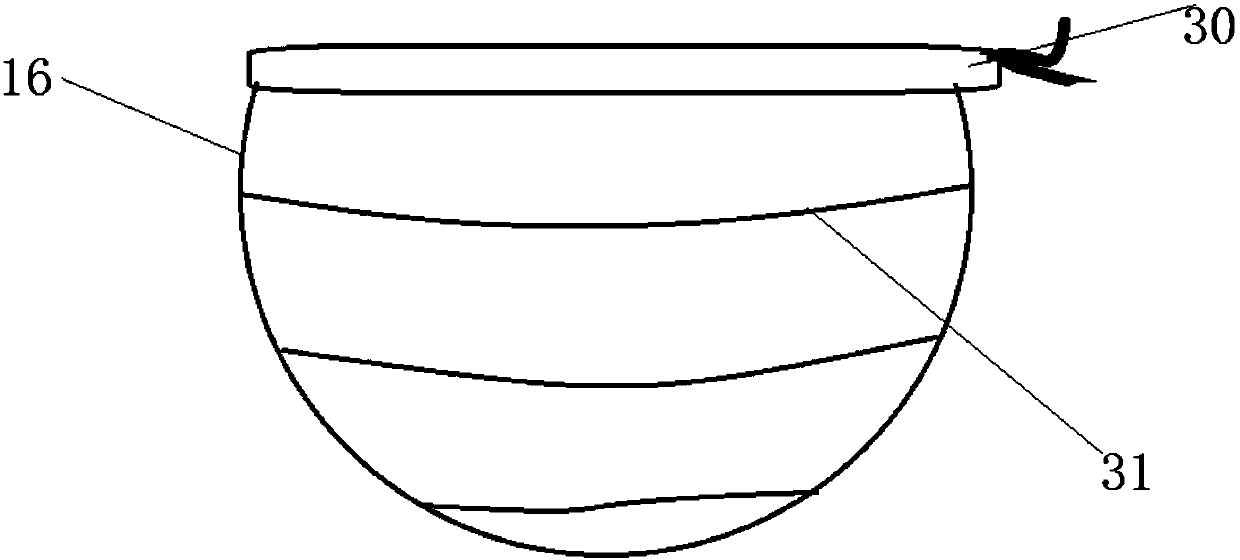

[0018] see Figure 1-3 , a chemical high-efficiency residue-free solid-liquid reaction device, including a guide wheel 1, a rotating shaft 2, a box body 4, a drain pipe 5, a heater 7, a water inlet pipe 10, a liquid flow meter 11, a camera 14, an air bag 15, and a gauze pocket 16. Gas purification device 18 and overflow pipe 19. The bottom surface of the box body 4 is provided with a guide wheel 1. The guide wheel 1 is provided with a hand brake. The guide wheel 1 is convenient for the device to move, saving time and effort. Inside the box body 4 is a Heater 7, the side wall of box body 4 is provided with thermometer 8 and PH detector 9, and heater 7 guarantees the most suitable temperature of reaction, and thermometer 8 measures the temperature in box body 4 at any time, and PH detector 9 measures the temperature in box body 4 The acidity and alk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com