Portable LED glue filling machine

A glue filling machine, portable technology, applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems affecting product quality, inconvenient movement or handling, affecting glue filling effect, etc., achieving obvious shock absorption effect and improving The effect of glue filling rate and convenient manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

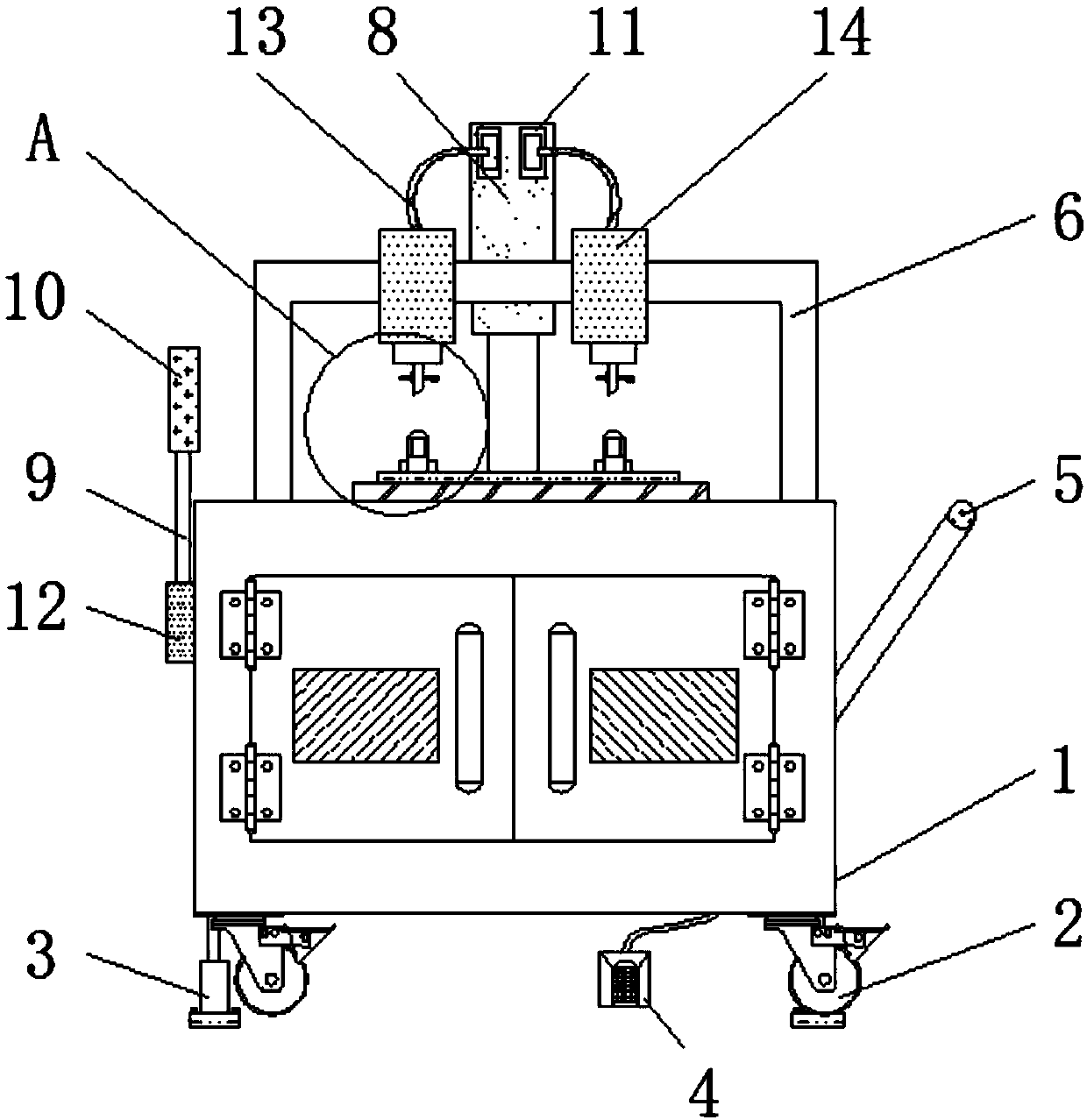

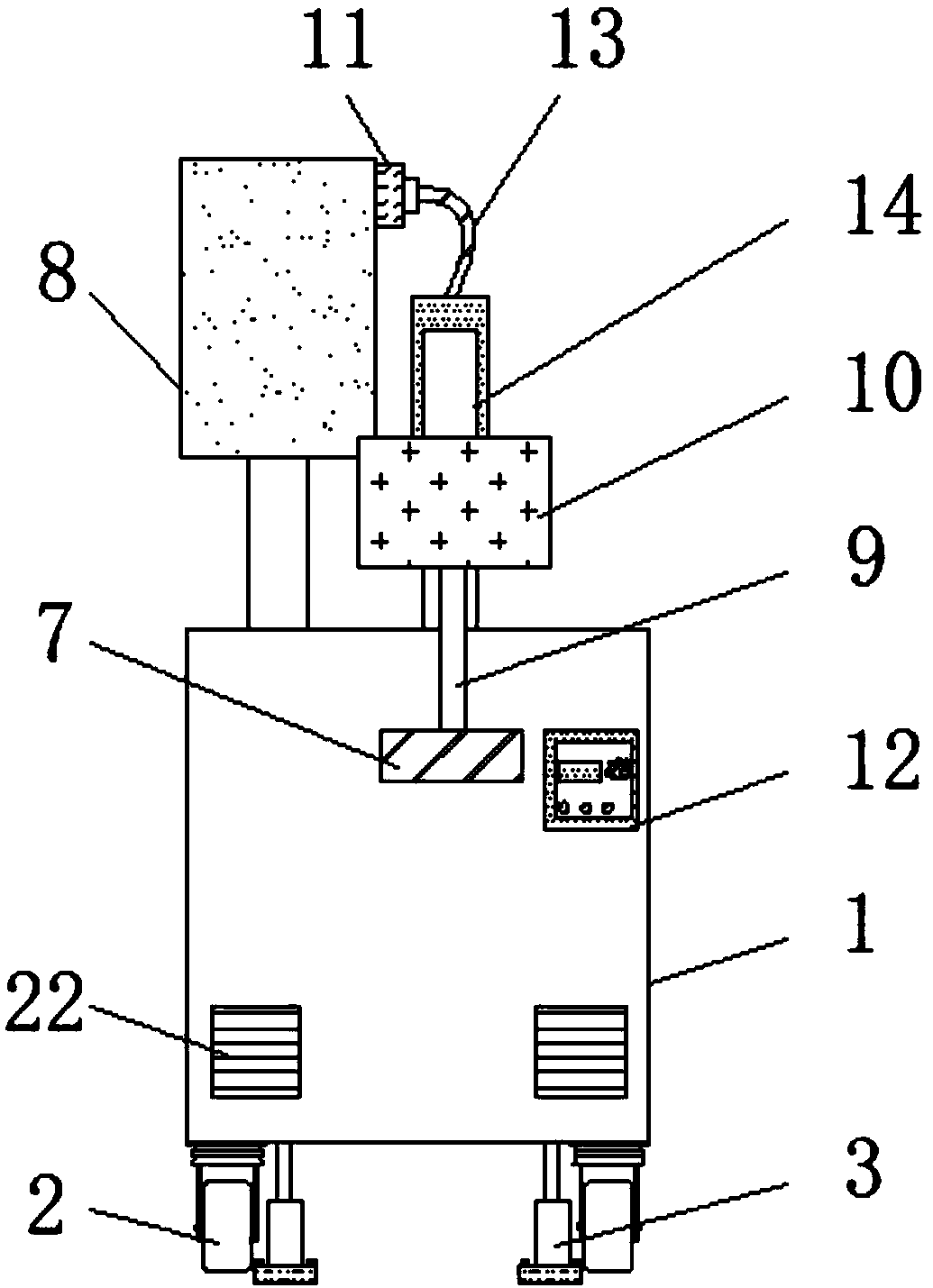

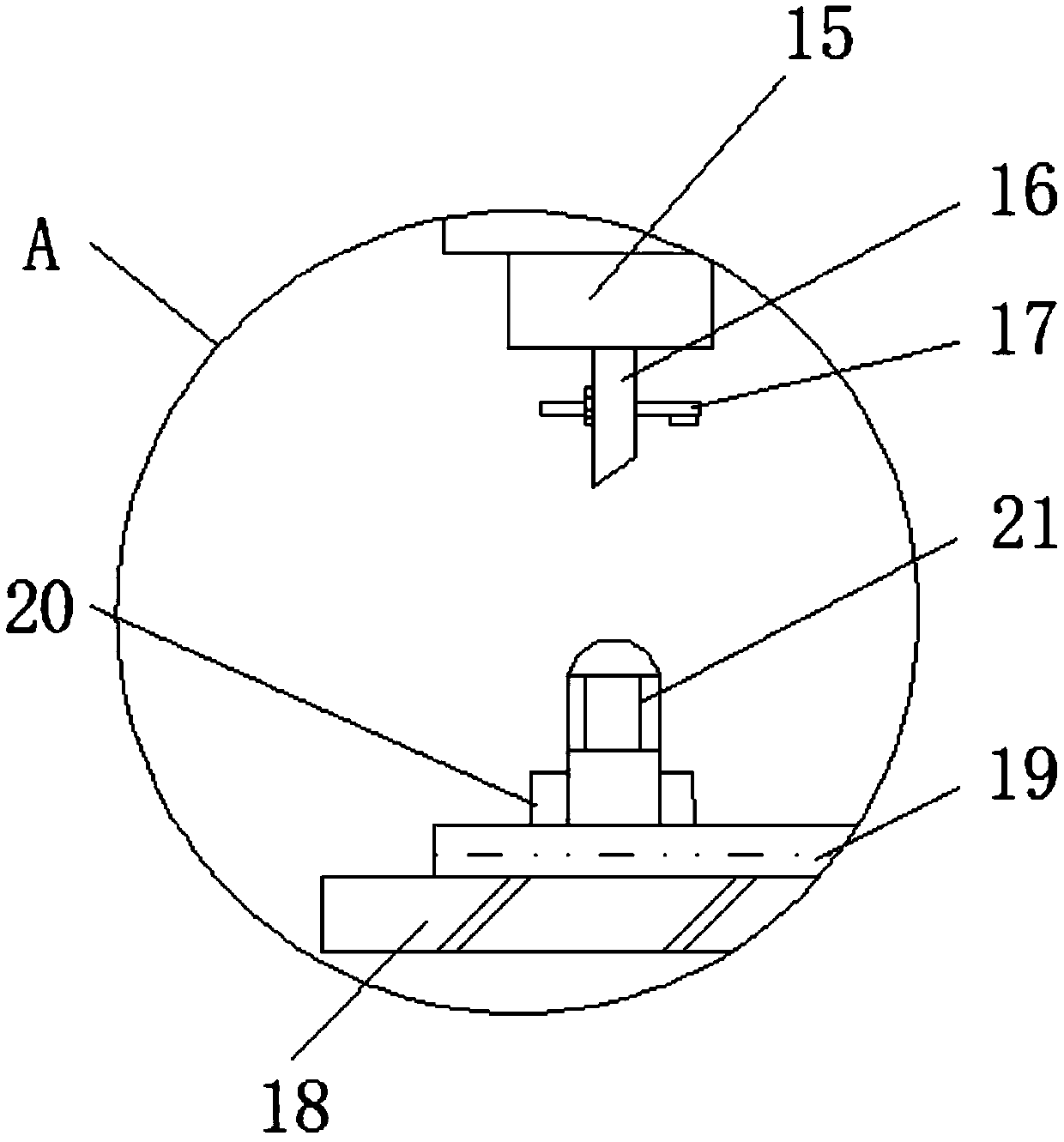

[0023] Example: such as Figure 1-3 As shown, the present invention provides a technical solution, a portable LED glue filling machine, including a workbench 1, the lower end of the workbench 1 is connected with a universal wheel 2, and the lower end of the workbench 1 is connected to the inner side of the universal wheel 2 There is a hydraulic rod 3, a foot switch 4 is set on the side of the lower end of the workbench 1 close to the universal wheel 2, and the side of the surface of the workbench 1 is provided with a push handrail 5, and the upper end of the workbench 1 is connected with a frame 6 , and the upper end of the workbench 1 is provided with a base 18 near the inner side of the frame 6, the other side surface of the workbench 1 is provided with a switch controller 12, and the inner side of the upper end of the workbench 1 is provided with a feeding air pump 8, and the switch controller 12 One side of the fixed block 7 is connected with a fixed block 7, and the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com