Lifting type gantry laser cutting machine cross beam

A laser cutting machine and beam technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problem that the synchronization of the rack and pinion transmission on both sides is difficult to control, increase the difficulty of on-site operators, and increase the economic cost of machine tools, etc. problems, to achieve the effects of improved controllable accuracy, short Z-axis travel, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

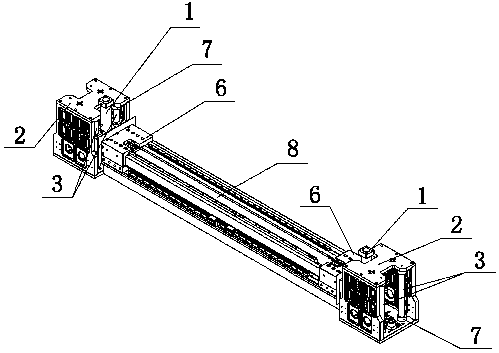

[0018] like figure 1 As shown, it is a schematic diagram of the overall structure of the beam of a liftable gantry laser cutting machine, including the lifting cylinder 1, the control beam lifter 2, the linear guide shaft 3, the zero point limit block 4, the oil pressure buffer 5, and the fixed beam support Plate 6, buffer rubber ring 7 and beam 8, the lifting cylinder 1, control beam lifter 2, linear guide shaft 3, zero point limit block 4, oil pressure buffer 5, fixed beam support plate 6 and buffer rubber ring 7 The left and right sides are evenly divided, the beam 8 is located in the middle position, and the left and right ends are respectively connected with the fixed beam support plate 6 by bolts, and the lifting air rod 1 in the control beam lifter 2 can drive the fixed beam support plate 6 and the beam 8 Lifting movement.

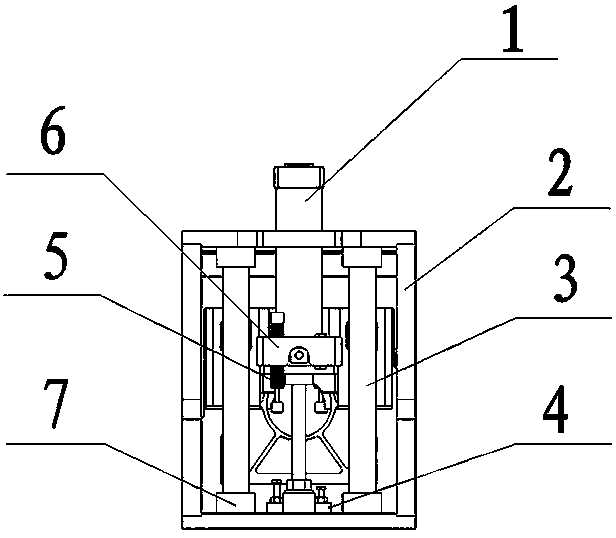

[0019] like figure 2 As shown, it is an end view of the beam of a liftable gantry laser cutting machine. The control beam lifter 2 is powered by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com