Jig external member for quickly replacing electrode

A jig and electrode technology, which is applied in the field of rapid electrode replacement jig kits, can solve the problems of low processing efficiency, high technical requirements, and high cost of use, and achieve the effects of improving work efficiency, easy to learn, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

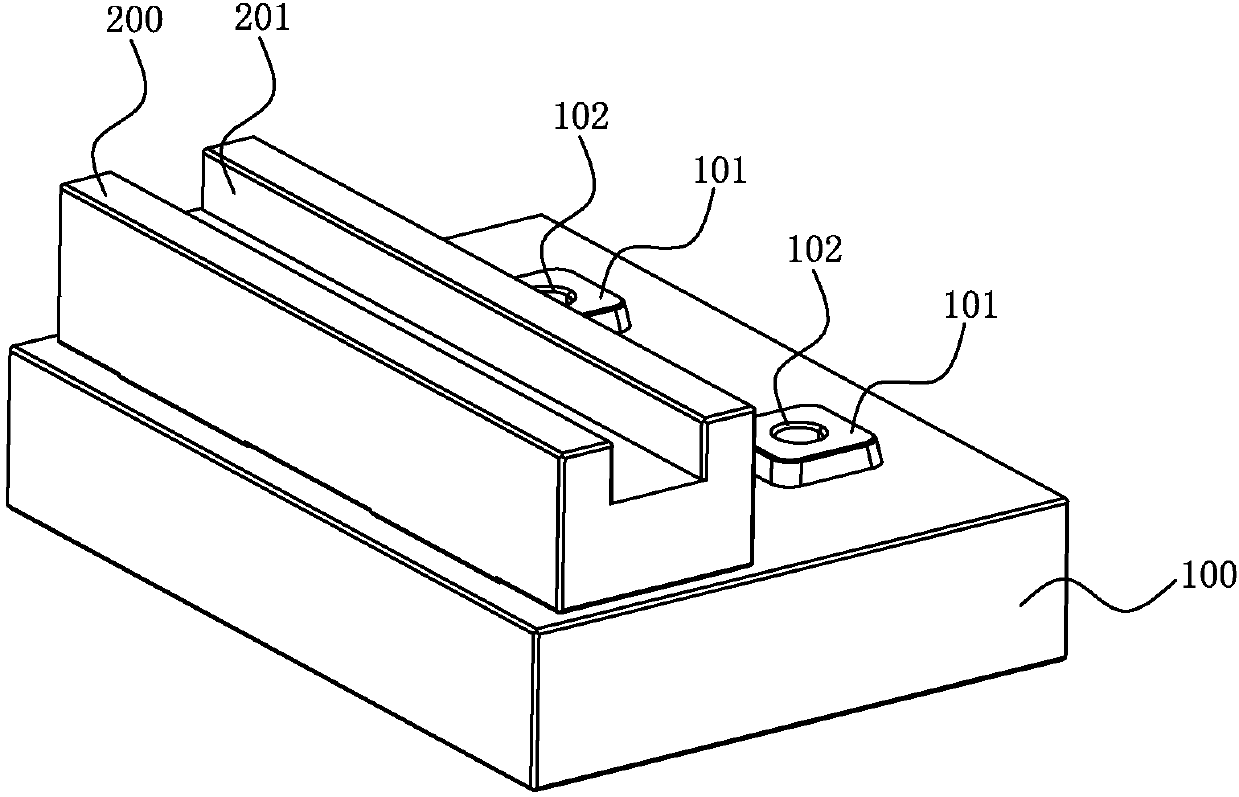

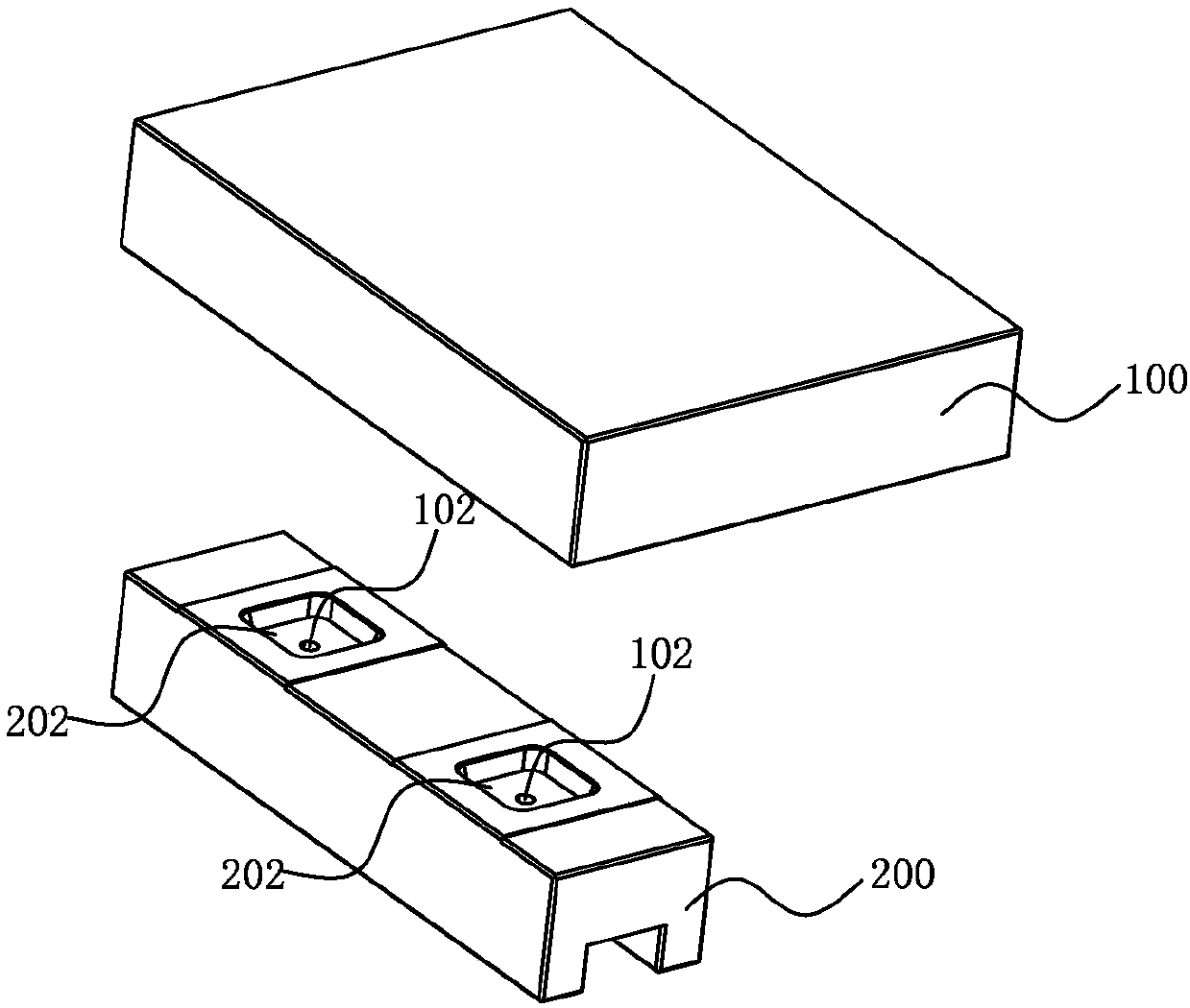

[0024] see Figure 1 to Figure 5 shown, where figure 1 A schematic diagram of the combination of the machined base and the jig in the electrode quick replacement jig set of the present invention is shown, figure 2 painted figure 1 An angle decomposition diagram of , image 3 painted figure 1 Another angle decomposition diagram of , Figure 4 painted figure 1 In the schematic diagram of the working state, Figure 5 A schematic diagram of the combination of the electric discharge machining base and the jig in the jig kit for rapid electrode replacement of the present invention is shown.

[0025] The electrode quick replacement jig set of the present invention is used for machining and EDM after electrode replacement. In a preferred embodiment, the electrode quick replacement jig set includes:

[0026] A machining base 100, the machining base 100 has a positioning block 101, and the machining base 100 is placed on a machining platform;

[0027] The electric discharge mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com