Detection mechanism and detection method for deviation of working position of mechanical arm

A technology of working position and detection mechanism, applied in the directions of manipulators, measuring devices, manufacturing tools, etc., can solve the problems of low efficiency, occupying production takt, affecting work efficiency, etc., and achieves high work efficiency, low cost, and automatic error-proof inspection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings.

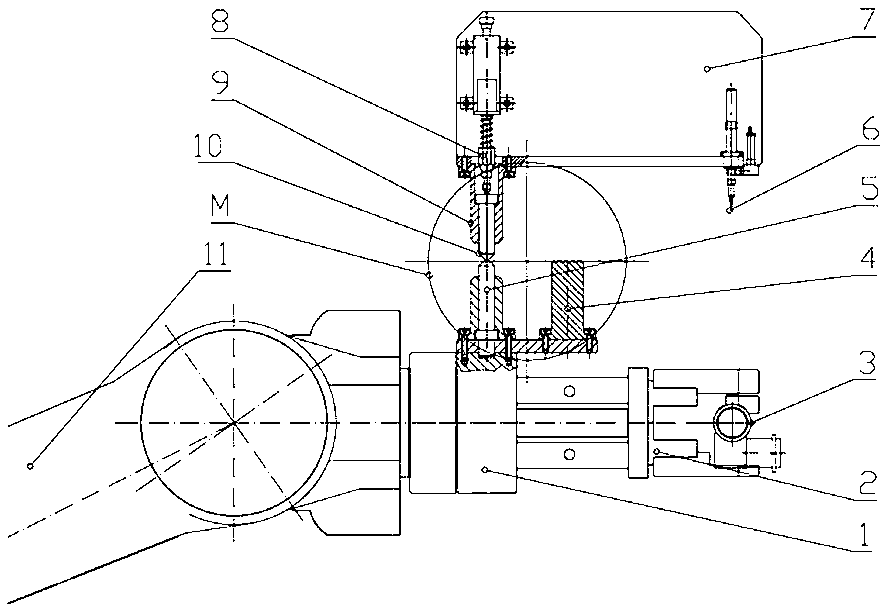

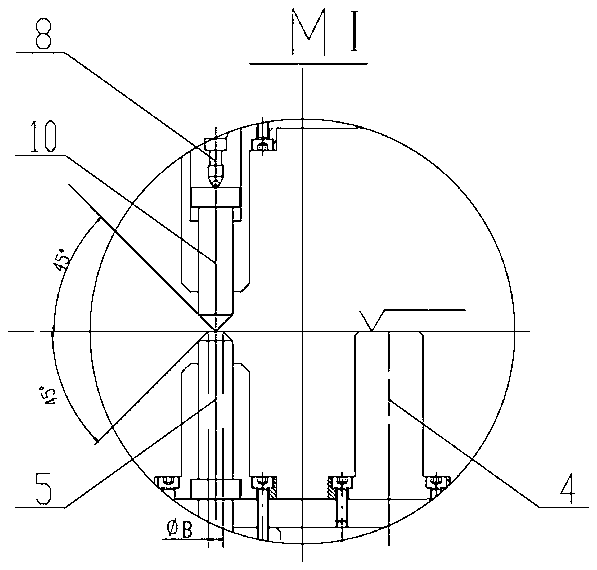

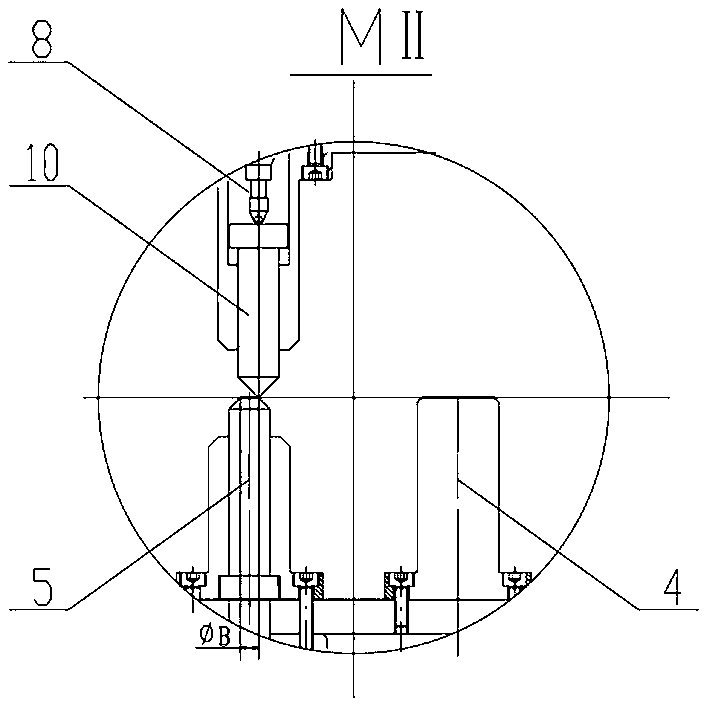

[0030] Such as figure 1 As shown, a detection mechanism for the deviation of the working position of the manipulator includes a mounting plate 7 arranged above the manipulator 11, a longitudinal guide sleeve 9 connected to the mounting plate 7, arranged in the guide sleeve 9 and protruding downward from the guide The tapered rod 10 of the sleeve 9, the displacement sensor 8 provided on the mounting plate 7 above the tapered rod 10 and the flat-end column 4 and the tapered-end flat-head column 5 installed side by side on the upper end of the manipulator 11 tooling 1, the detection end of the displacement sensor 8 is against At the top of the top cone rod 10, the guide sleeve 9 is provided with a limit edge, and the pointed cone rod 10 is provided with a limit end at the upper end of the limit edge. The top surface of the column 4 is on the same plane as the top surfa...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap