Oil seal mold

A technology for oil seals and molds, applied in the field of molds for oil seals, can solve problems such as failure to meet design requirements, seal failure, and affect product quality, and achieve the effects of improving production efficiency, reducing assembly errors, improving production accuracy and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

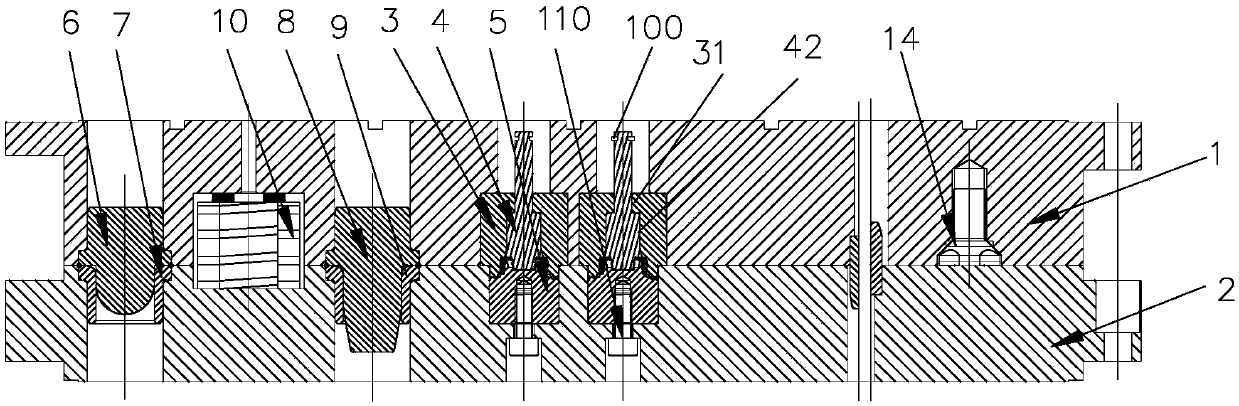

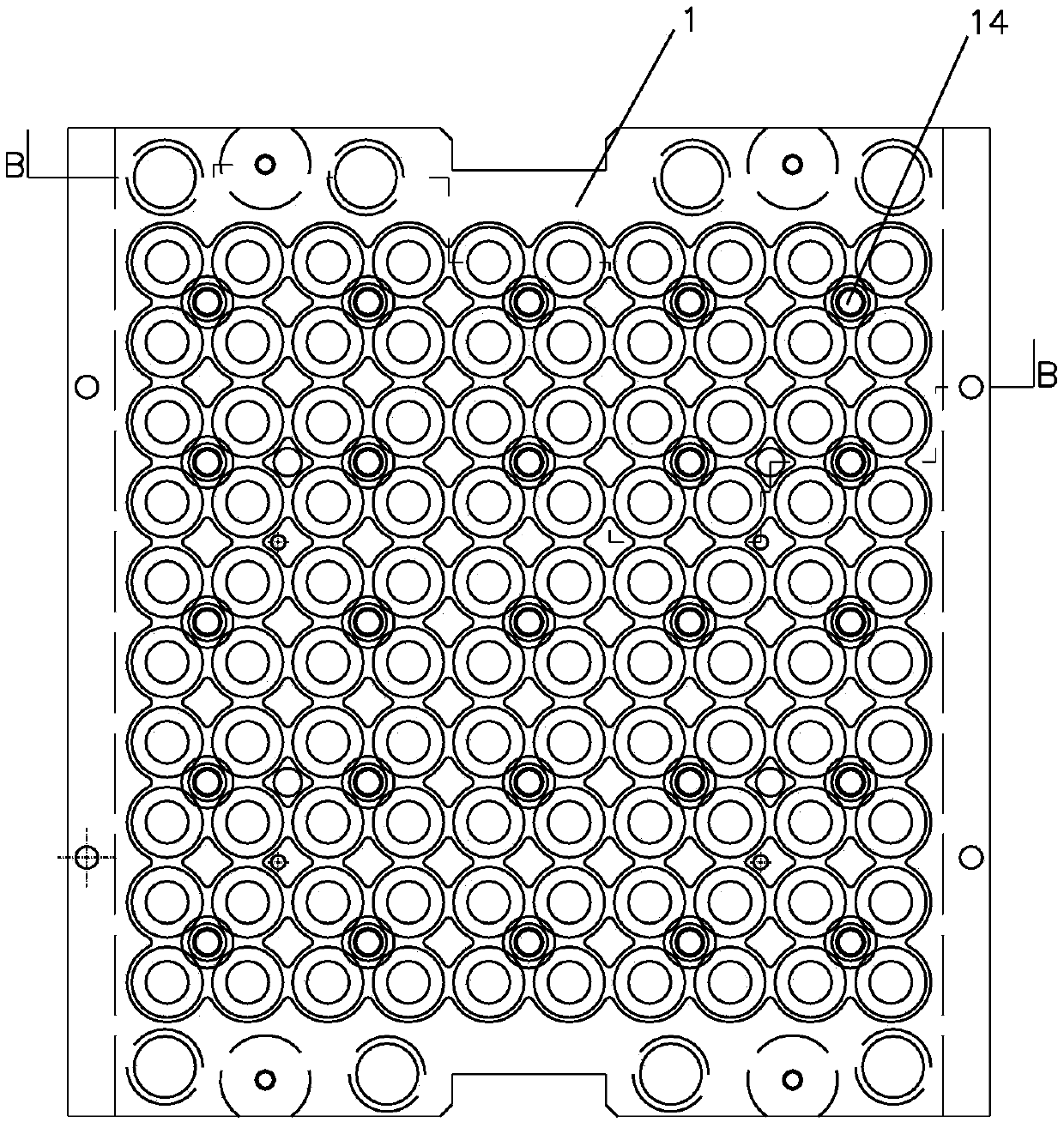

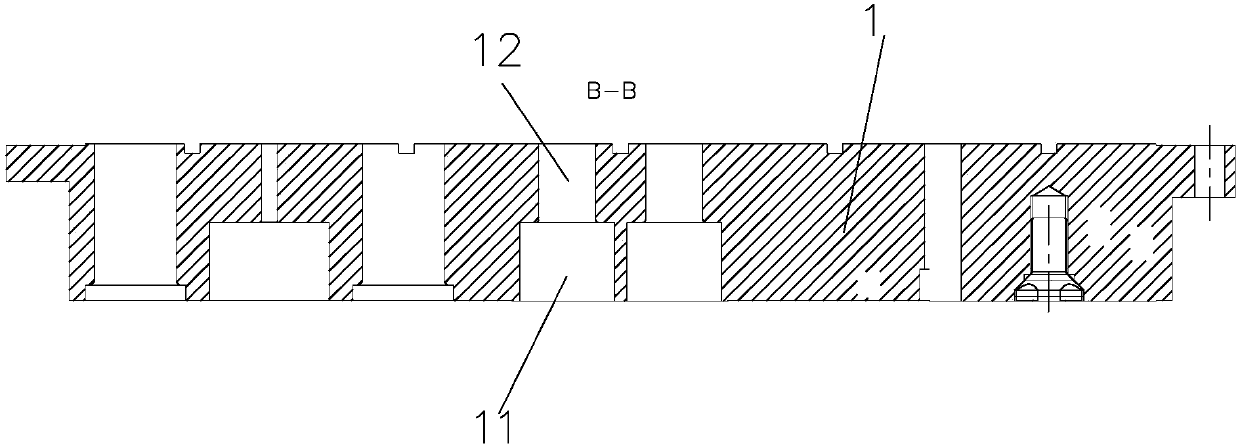

[0026] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

[0027] Such as Figure 1~6 Shown, a kind of mold for oil seal, it comprises:

[0028] Upper template 1, at least one upper mold core group is installed on the upper template 1, and the upper mold core group includes an upper outer mold core 3 and an upper inner mold core 4, and the upper outer mold core 3 is installed on the upper template 1 Above, the upper inner mold core 4 can be moved up and down and installed on the corresponding upper outer mold core 3, and the upper outer mold core 3 and the corresponding upper inner mold core 4 cooperate to form a cavity; in this embodiment, the upper There are 100 sets of mold core sets, but not limited thereto;

[0029] The lower template 2, at least one lower mold core 5 is installed on the lower templ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com