Quick heating decorative paper knurling roll

A technology for decorative paper and embossing rollers, applied in the direction of machining/deformation, etc., can solve the problems of affecting production efficiency, waiting for temperature rise, etc., to achieve the effect of improving work efficiency, reducing waiting time, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

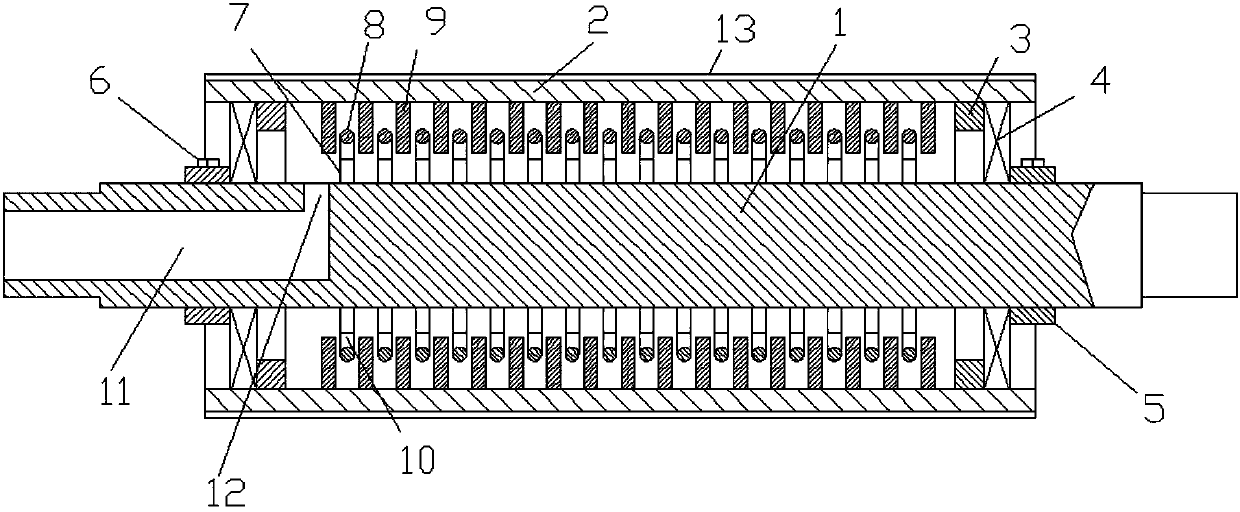

[0014] Combine below figure 1 And further illustrate the technical solution of the present invention through specific examples.

[0015] A fast heating decorative paper embossing roller, comprising: a fixed shaft 1, a roller 2 and a heating ring 8, the roller 2 is concentrically arranged outside the fixed shaft 1, and the two ends of the inner hole of the roller 2 are respectively A bearing 4 is arranged between the outer circle of the fixed shaft 1 for rolling support, so as to facilitate the rotation of the roller 2 .

[0016] Annular fins 9 are arranged at intervals on the inner wall of the roller 2, and there is a gap between adjacent annular fins 9, and a circular heat insulating sheet 7 corresponding to the gap is arranged on the fixed shaft 1, and the heating ring 8 are respectively arranged on the outer circle of the circular heat insulation sheet 7 and located in the gap, using multiple heating rings 8 to heat respectively, and quickly absorb heat through the annular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com