Automobile front collision energy absorption protection structure

A frontal collision and protection structure technology, applied in bumpers, vehicle parts, vehicle safety arrangements, etc., can solve problems such as insufficient energy absorption, and achieve a stable and efficient energy absorption process, reasonable structure, and strong safety protection capabilities. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

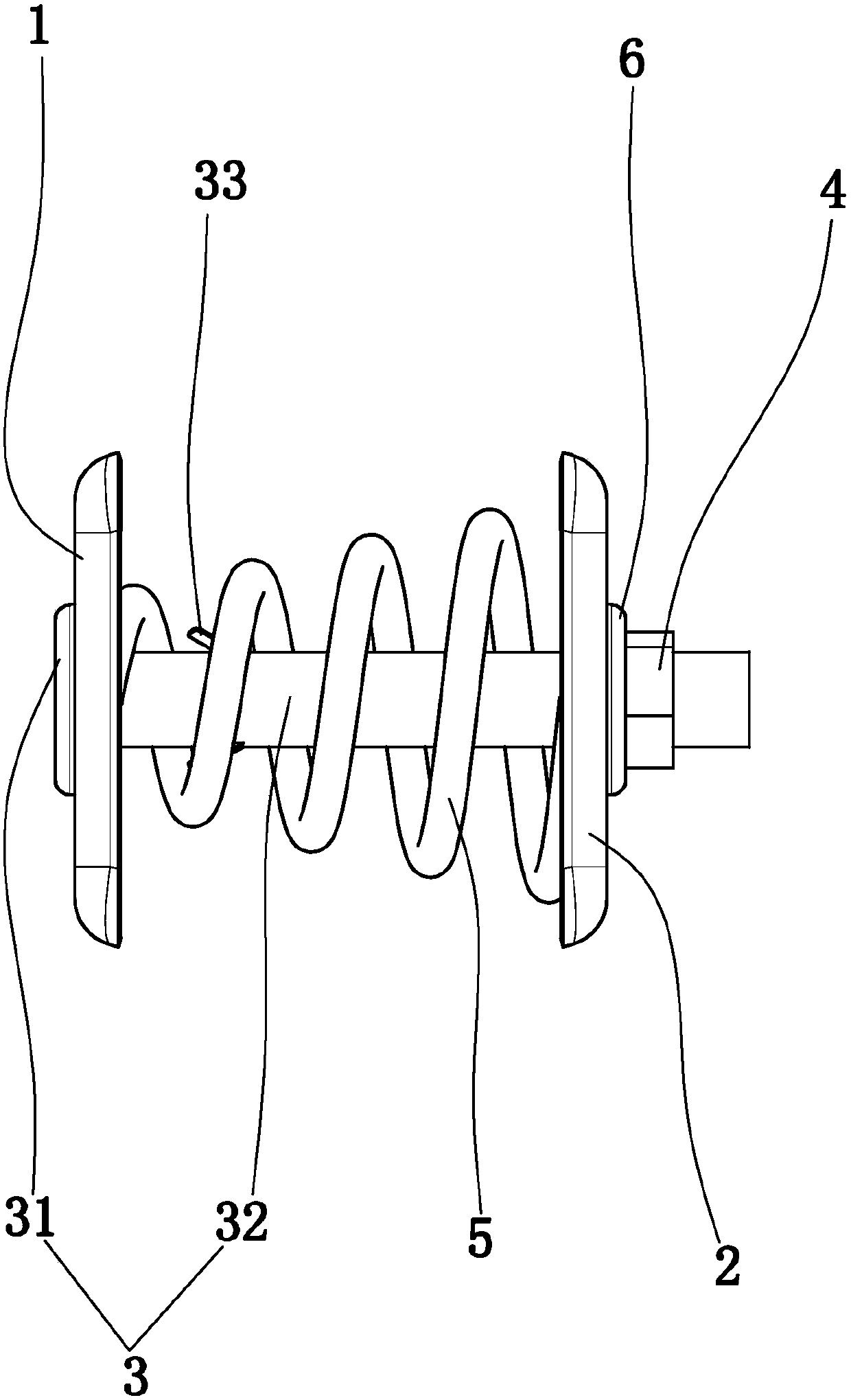

[0023] Embodiment 1: as figure 1 In the shown embodiment, a kind of energy-absorbing protection structure of automobile frontal collision, comprises

[0024] Energy-absorbing front seat 1, energy-absorbing rear seat 2, fixing bolt 3, fixing nut 4 and energy-absorbing spring 5, the fixing bolt includes a bolt head 31 welded with the front anti-collision beam of the automobile and a stud welded with the front longitudinal beam of the automobile 32;

[0025] The stud passes through the energy-absorbing front seat and the energy-absorbing rear seat, the energy-absorbing spring is sleeved outside the stud, and the energy-absorbing spring is located between the energy-absorbing front seat and the energy-absorbing rear seat;

[0026] The fixing nut is threadedly connected with the stud, and on the axial direction of the stud: the bolt head, the energy-absorbing front seat, the energy-absorbing spring, the energy-absorbing back seat and the fixing nut are arranged in sequence.

[00...

Embodiment 2

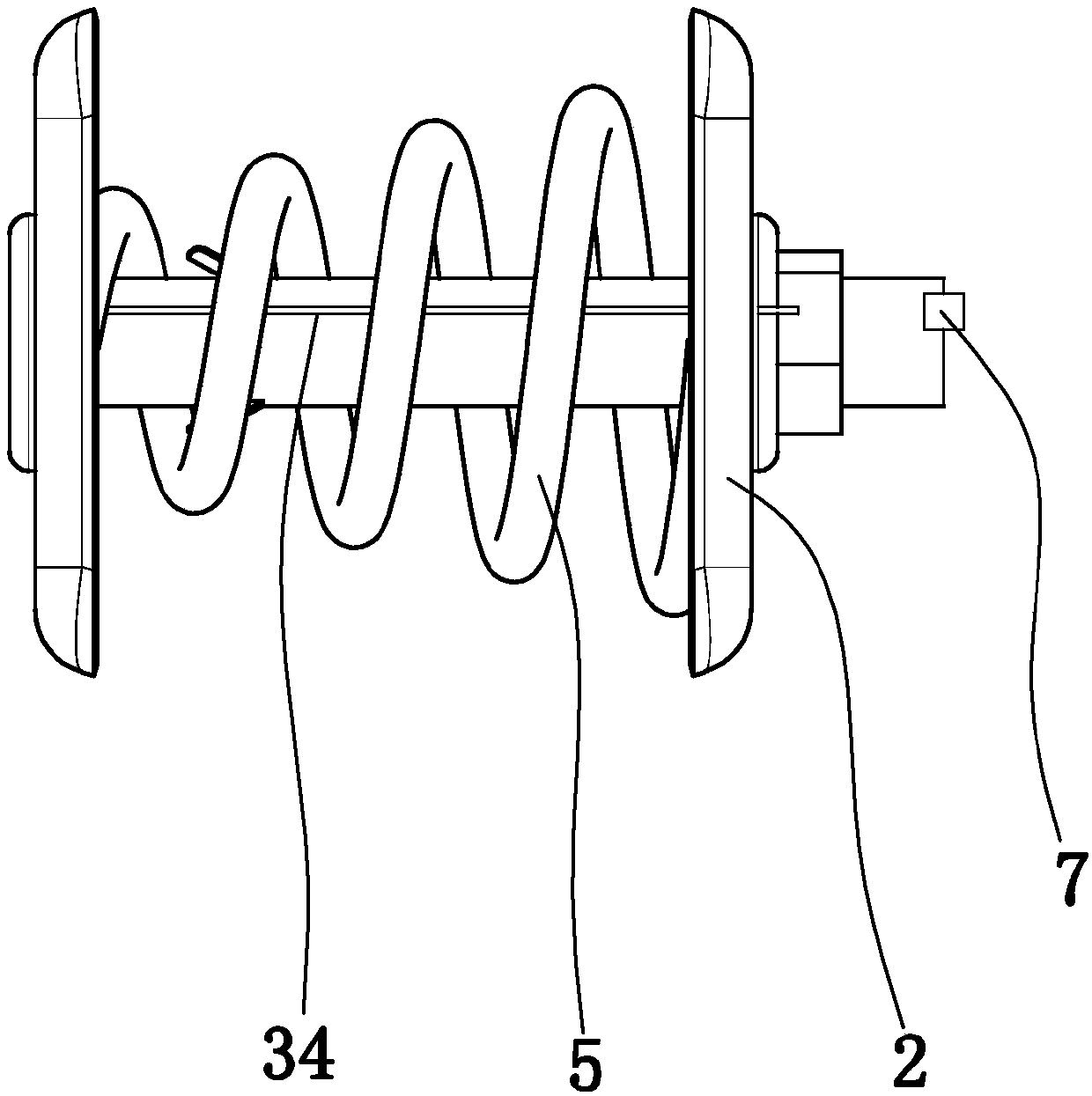

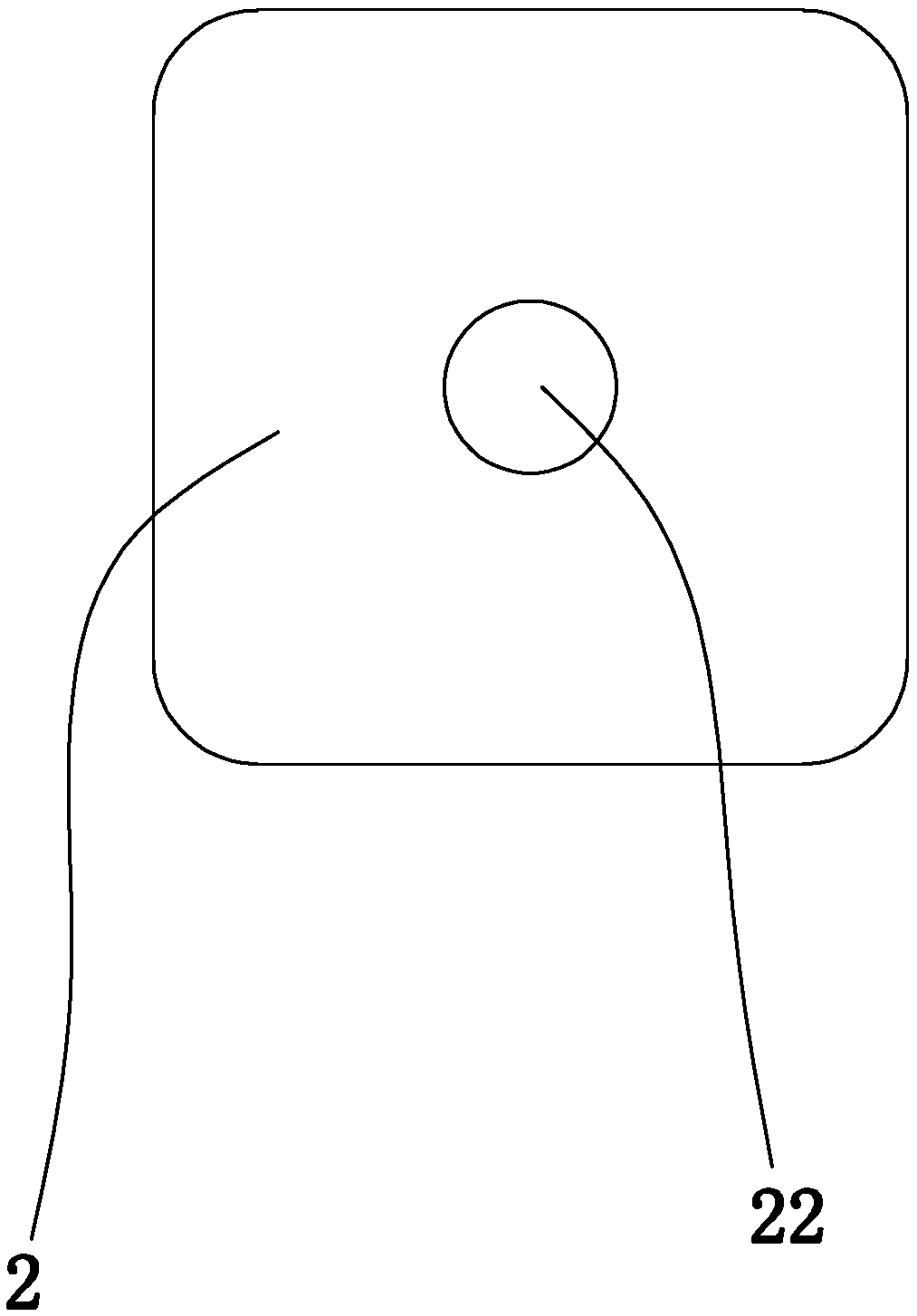

[0032] Embodiment 2: the basic structure and implementation mode of this embodiment are the same as embodiment 1, and its difference is, as Figure 2 to Figure 4 As shown in , the energy-absorbing rear seat is provided with a number of barb extrusion holes 21 corresponding to the elastic barbs one by one, the energy-absorbing front seat is provided with a front seat middle hole 11, and the energy-absorbing rear seat is provided with a middle hole 11 of the rear seat. Hole 22, stud passes the middle hole of the front seat, and stud passes the middle hole of the rear seat, and the barb squeezes through the hole and communicates with the middle hole of the rear seat. The existence of extrusion holes can reduce the difficulty of elastic barbs passing through the energy-absorbing rear seat and improve the smoothness of work.

[0033] The energy-absorbing front seat is provided with a guide rod 34, and the energy-absorbing rear seat is provided with a guide hole slidingly matched wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com