Climbing robot and safety rope automatic suspension system for hanging safety rope

A technology of safety ropes and robots, which is applied in the field of electric power maintenance robots, can solve the problems of large safety hazards and the inability to realize worker safety protection, and achieve the effect of reducing safety hazards and conveniently hanging safety ropes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

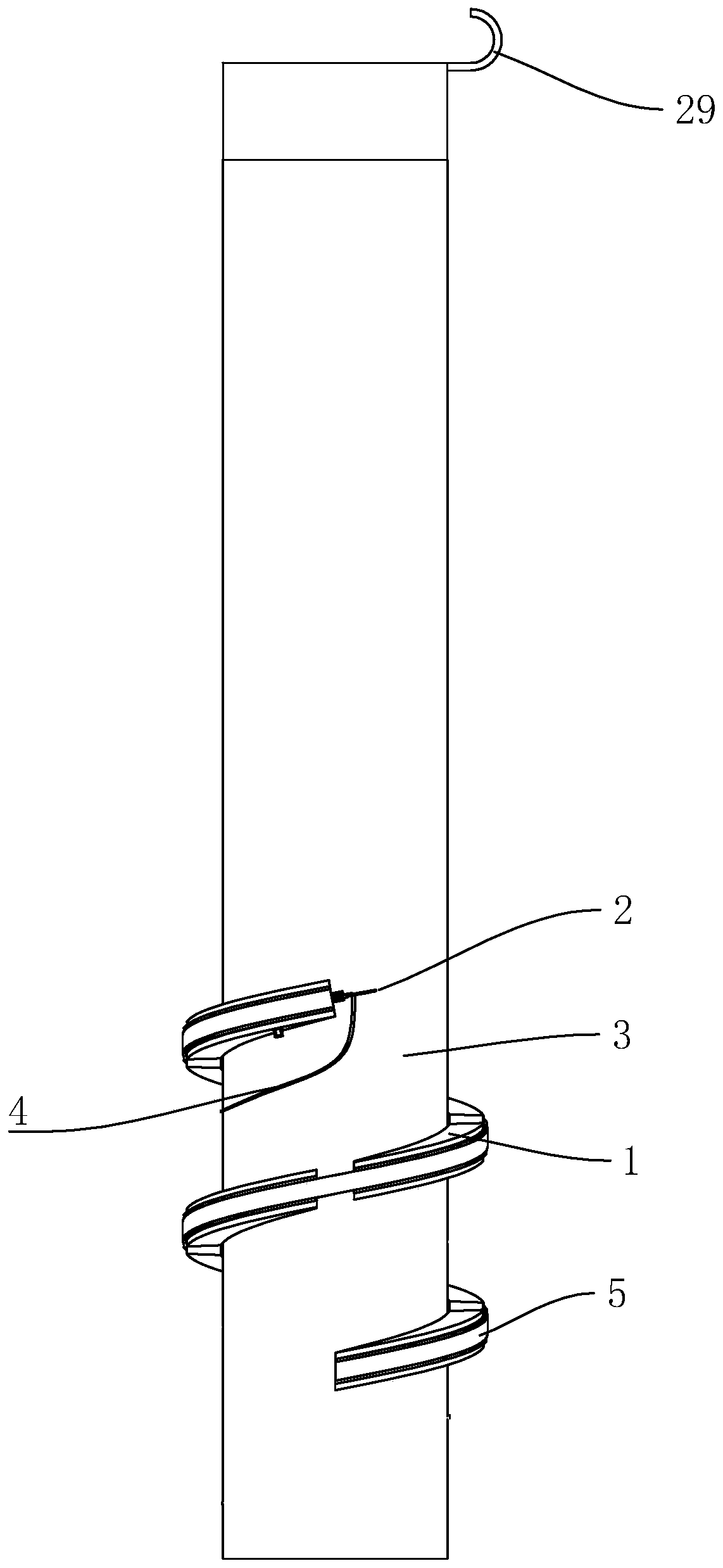

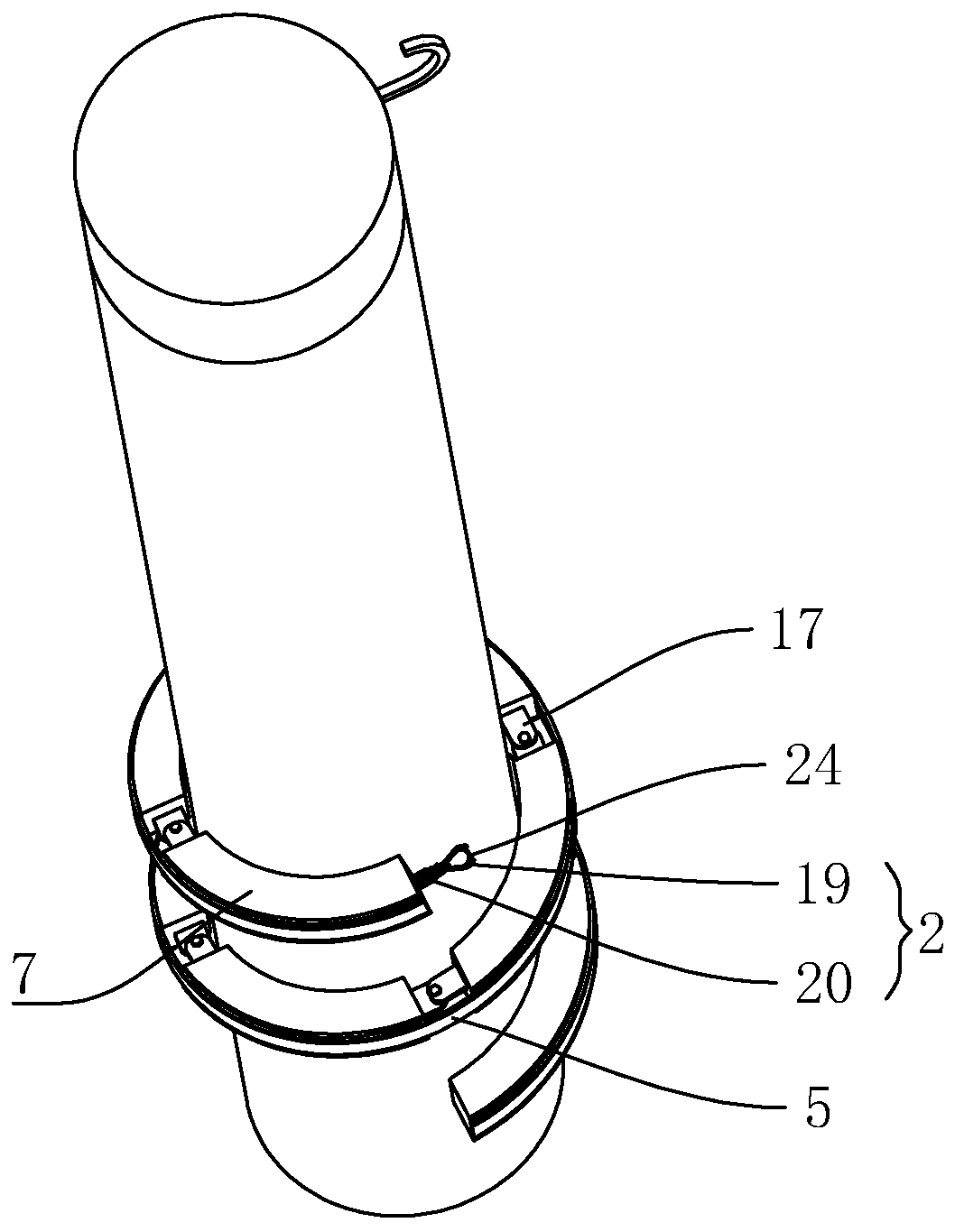

[0038] Embodiment 1: a kind of climbing robot for hanging safety rope, as figure 1 , 2 Shown, comprise running mechanism 1 and hanging rope mechanism 2. The traveling mechanism 1 is used for climbing the utility pole 3, and the hanging rope mechanism 2 is used for installing the safety rope 4. The running gear 1 is in a spiral shape as a whole, and includes several running components 7 , and elastic metal sheets 5 for maintaining the shape of the running gear 1 are arranged on the periphery of the running components 7 . In order to ensure a better shape memory retention effect, the elastic metal sheet 5 in this embodiment uses a memory alloy.

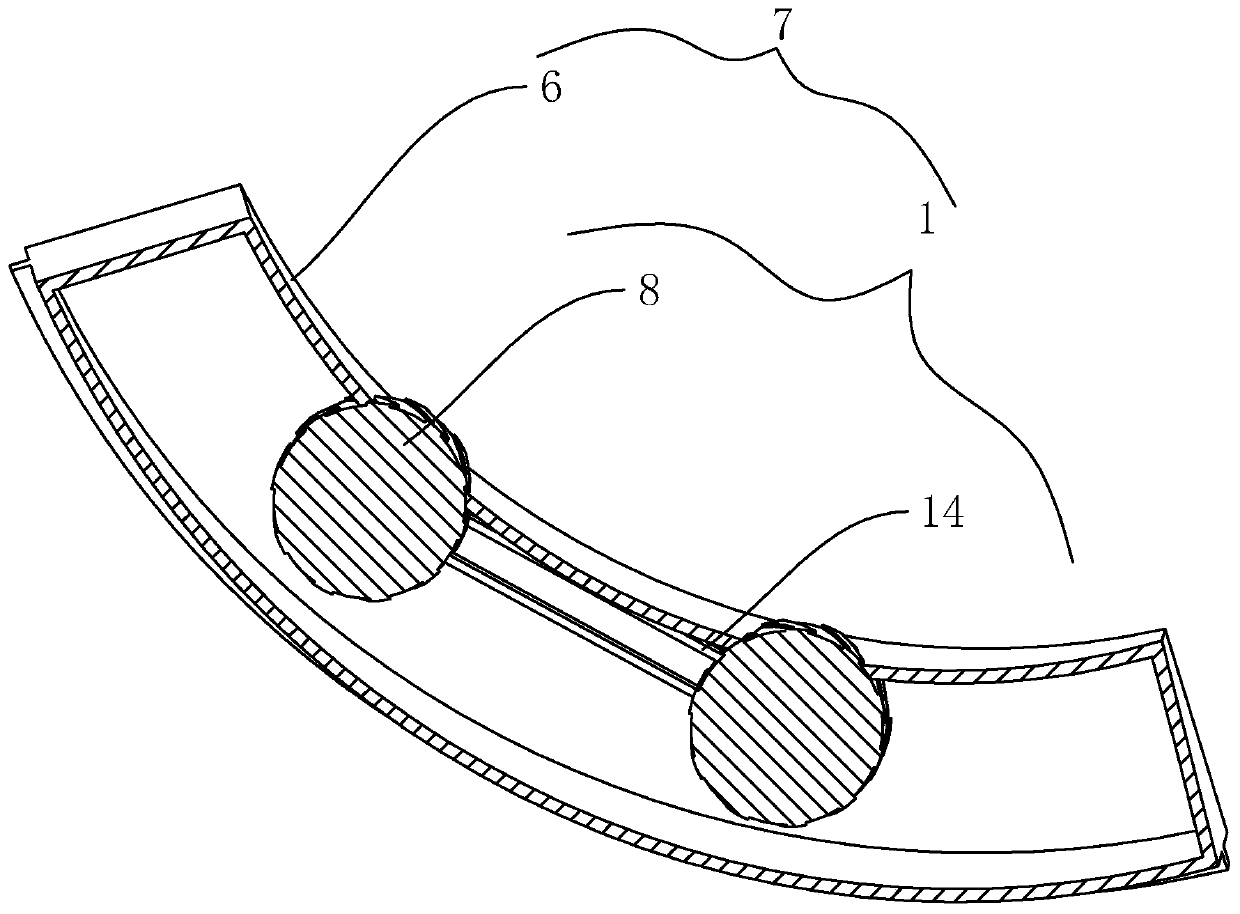

[0039] Such as image 3 , 4 As shown, any walking assembly 7 includes a housing 6 , the housing 6 is hollow inside and has an opening on the side close to the utility pole 3 . A traveling wheel 8 is arranged inside the casing 6, and patterns are arranged on the traveling wheel 8. The pattern is divided into a first pattern 9 and a...

Embodiment 2

[0046] Embodiment 2: A safety rope automatic suspension system, the difference from Embodiment 1 is that, as figure 1 , 7 As shown, it also includes a tracing hook, which is arranged on the top of the utility pole, and includes a hook body 29 , a rotating mechanism 30 and a controller 31 . The hook body 29 is used to provide a suspension point for the safety rope 4 . The hook body 29 is fixedly arranged on the rotating mechanism 30 , and the rotating mechanism 30 is arranged on the top end of the utility pole 3 .

[0047] Rotary mechanism 30 comprises turntable body 32, and the top of turntable body 32 is provided with roller 33, and the center of the bottom surface of turntable body 32 is provided with accommodating groove 34, and accommodating groove 34 is provided with decelerating motor 35, and the rotating shaft of decelerating motor 35 is vertically upward. , and is connected with the turntable body 32, the bottom surface of the geared motor 35 is arranged on the top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com