M-cresol and p-cresol mixture refining method

A refining method and technology for p-cresol are applied in the field of coal chemical industry, and can solve the problems of mixing m-p-cresol and low purity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

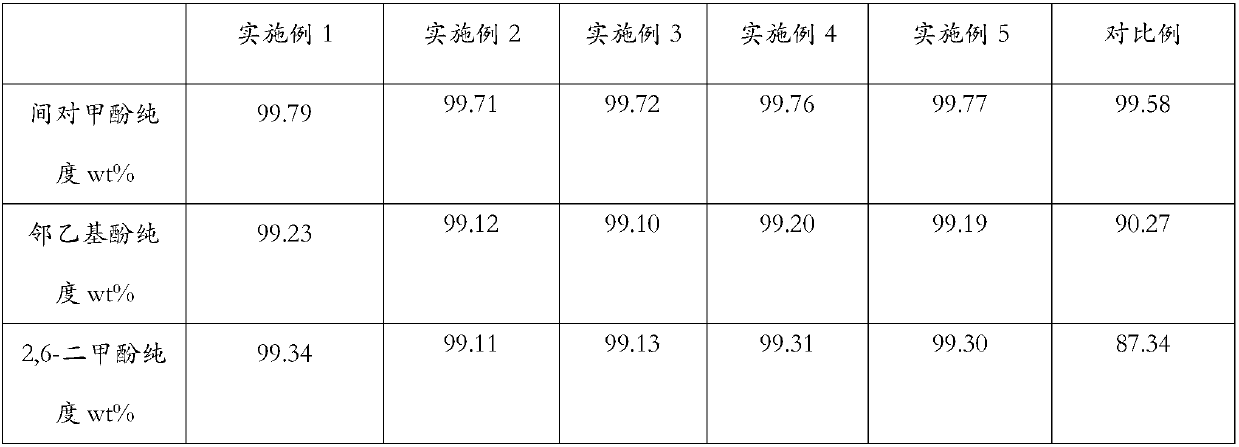

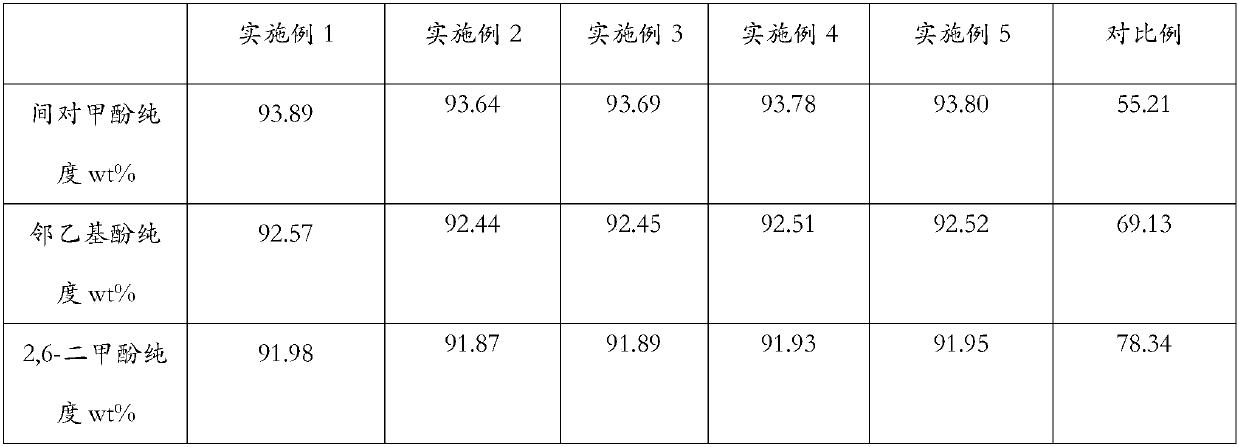

Embodiment 1

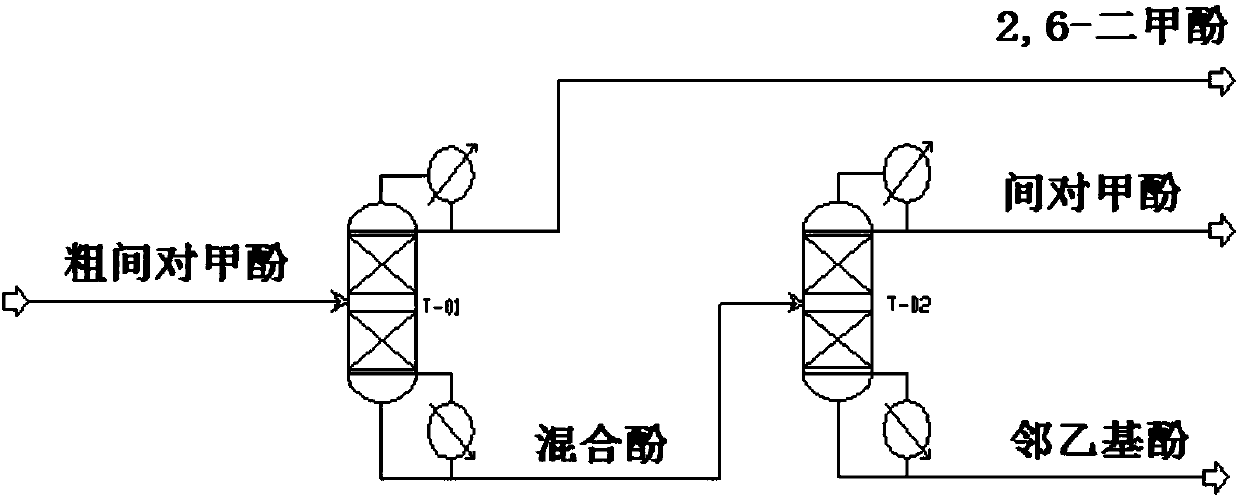

[0027] The present embodiment provides a kind of refining method of m-p-cresol, adopts figure 1 The shown device comprises the steps of:

[0028] In this embodiment, T-01 is a light removal tower, T-02 is a weight removal tower, and the specific surface of the filler in the light removal tower and the weight removal tower is 1000.

[0029] (1) After heating the crude m-p-cresol to 105°C, it is passed into the light removal tower T-01 for rectification treatment. The operating pressure of the rectification tower is 1KPa, the temperature is 83°C, and the reflux ratio is 20. The theoretical tower Plate number is 120, obtains tower top distillate and tower bottom distillate;

[0030] The overhead distillate is 2,6-xylenol, and the bottom distillate is a mixed phenol containing o-ethylphenol and m-p-cresol;

[0031] (2) Pass the tower still distillate of light removal tower T-01 into rectification treatment in the weight removal tower T-02, the tower top operating pressure of rec...

Embodiment 2

[0033] The present embodiment provides a kind of refining method of m-p-cresol, comprising the steps:

[0034] (1) After preheating the crude m-p-cresol to 60°C, pass it into the light removal tower for rectification treatment, the operating pressure of the rectification tower top is 0.05KPa, the temperature is 54°C, the reflux ratio is 10, and the theoretical plate Number is 130, obtains overhead distillate and tower bottom distillate;

[0035] The overhead distillate is 2,6-xylenol, and the bottom distillate is a mixed phenol containing o-ethylphenol and m-p-cresol;

[0036] (2) Pass the tower still distillate of the light removal tower into the weight removal tower for rectification treatment. The operating pressure of the rectification tower top is 400KPa, the tower top temperature is 269°C, the reflux ratio is 30, and the number of theoretical plates is It is 130 pieces. The overhead distillate of the weight-removing tower is refined m-p-cresol, and the bottom distillate...

Embodiment 3

[0038] The present embodiment provides a kind of refining method of m-p-cresol, comprising the steps:

[0039] (1) After preheating the crude m-p-cresol to 130°C, pass it into the light removal tower for rectification treatment, the operating pressure of the rectification tower top is 9KPa, the temperature is 135°C, the reflux ratio is 25, and the number of theoretical plates Be 180 pieces, obtain tower top distillate and tower bottom distillate;

[0040] The overhead distillate is 2,6-xylenol, and the bottom distillate is a mixed phenol containing o-ethylphenol and m-p-cresol;

[0041] (2) Pass the tower still distillate of the light removal tower into the weight removal tower for rectification treatment. The operating pressure of the rectification tower top is 100KPa, the tower top temperature is 204°C, the reflux ratio is 12, and the number of theoretical plates is It is 60 pieces. The overhead distillate of the weight-removing tower is refined m-p-cresol, and the bottom d...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap