A kind of toughened type pentaerythritol acrolein resin and preparation method thereof

A technology of pentaerythritol acrolein resin and pentaerythritol, applied in the field of toughened pentaerythritol acrolein resin and its preparation, to achieve the effect of improving toughness and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A toughened pentaerythritol acrolein resin, the formulation of which consists of: pentaerythritol acrolein resin: 91 parts, benzyl alcohol: 9 parts, diethyl sulfate: 4.5 parts.

[0027] The preparation of the toughened type pentaerythritol acrolein resin mainly includes the following steps:

[0028] (1) Pretreatment of pentaerythritol acrolein resin: first, preheat the resin in an oven at 50°C, then pass through a 200-mesh screen to remove large particle aggregates, and then treat the resin under vacuum for more than 30 minutes, and the vacuum degree is ≤ -0.090Mpa, the temperature is 50°C, so as to remove the small molecular components, and set aside;

[0029] (2) Water removal treatment of the catalytic curing agent: treat the catalytic curing agent under vacuum conditions for more than 30 minutes, the vacuum degree is ≤ -0.090Mpa, and the temperature is 50°C to remove the water molecules in it, and set aside.

[0030] (3) Ingredients: take the pretreated resin, the ...

Embodiment 2

[0038] A toughened pentaerythritol acrolein resin, the formulation of which consists of: pentaerythritol acrolein resin: 87 parts, benzyl alcohol: 13 parts, diethyl sulfate: 4.4 parts.

[0039] The preparation method is the same as in Example 1.

[0040] The various indicators of the obtained cured product are as follows:

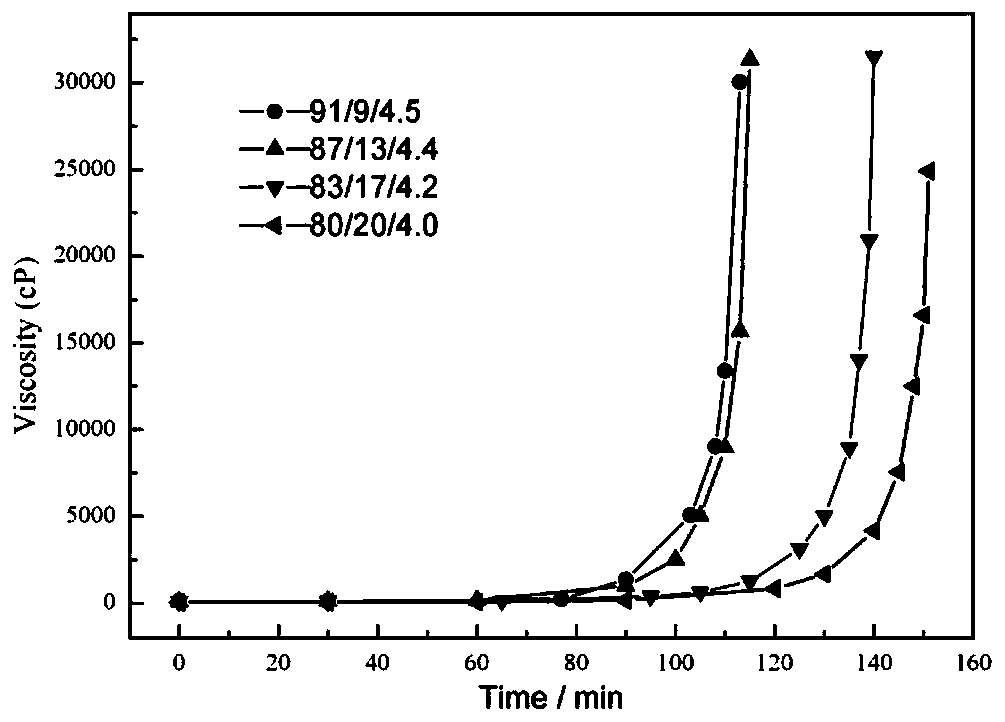

[0041] (1) The viscosity of the material changes as figure 2 , the initial viscosity is 74 centipoise, and the viscosity after curing for 0.5h, 1h, 1.5h, 1.8h and 1.9h is 96 centipoise, 162 centipoise, 1002 centipoise, 8964 centipoise and 31325 centipoise respectively;

[0042] (2) Mechanical properties: tensile strength 14.82MPa, elongation at break 32.51%;

[0043] (3) After the film is impacted by a sudden change in temperature from -40 to 70°C, the appearance has no cracks or blocks.

Embodiment 3

[0045] A toughened pentaerythritol acrolein resin, the formulation of which consists of: pentaerythritol acrolein resin: 83 parts, benzyl alcohol: 17 parts, diethyl sulfate: 4.2 parts.

[0046] The preparation method is the same as in Example 1.

[0047] The various indicators of the obtained cured product are as follows:

[0048] (1) The viscosity of the material changes as figure 2 , the initial viscosity is 70 centipoise, and the viscosity after curing for 0.5h, 1h, 1.5h, 2h and 2.3h is 88 centipoise, 106 centipoise, 376 centipoise, 3131 centipoise and 31500 centipoise respectively;

[0049] (2) Mechanical properties: tensile strength 4.11MPa, elongation at break 63.17%;

[0050] (3) After the film is impacted by a sudden change in temperature from -40 to 70°C, the appearance has no cracks or blocks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap