Semi-steel smelting method

A technology of steel smelting and ladle, applied in the field of converter steelmaking, can solve the problem of low carbon content of semi-steel finished products, achieve the effect of increasing carbon content, increasing reaction interface area, and simple adding method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

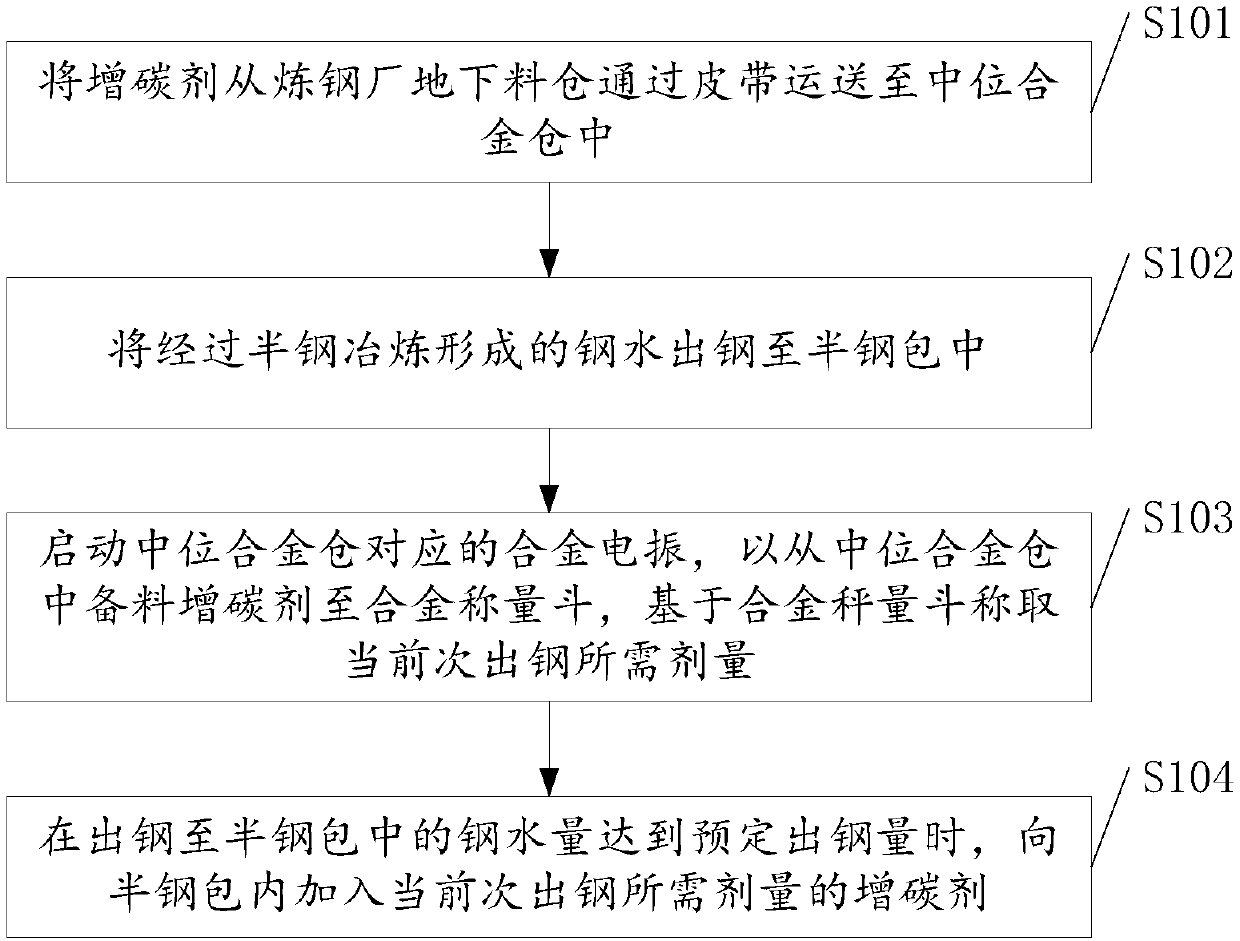

Method used

Image

Examples

example 1

[0045] After smelting the semi-steel, start to tap the steel. From the moment of tapping 2 minutes, add the weighed 1102kg recarburizer into the semi-steel ladle. The process of adding the recarburizer is carried out at the same time as the tapping. After tapping, the slag is blocked by a slide , Tapping takes 6 minutes, and tapping ends.

example 2

[0047] After the half-steel is smelted, the tapping starts. At the time of tapping for 1 minute and 35 seconds, add the weighed 1050kg recarburizer into the semi-ladle. The feeding process of the recarburizer is carried out at the same time as the tapping. It took 5 minutes and 45 seconds to block the slag and tap the steel.

example 3

[0049] After smelting the semi-steel, start to tap steel. From the moment of tapping for 1 minute and 50 seconds, add 1085kg carburant to the semi-ladle. The process of adding carburant and tapping is carried out at the same time. After tapping, the slag is blocked by a slide plate. Tapping took 6 minutes and 10 seconds.

[0050] The molten steel samples obtained before tapping and the molten steel samples in the half-ladle were sampled and tested, and the comparative composition changes are shown in Table 1 and Table 2 below:

[0051] Table 1. Composition content of molten steel samples obtained before tapping (the balance is Fe)

[0052] the case

C

Si

mn

P

S

1

3.1883%

0.0133%

0.0491%

0.0212%

0.0045%

2

3.2833%

0.0171%

0.0385%

0.0221%

0.0032%

3

3.2457%

0.0143%

0.0470%

0.0337%

0.0038%

[0053] Table 2. Composition content of molten steel samples in half ladle (mass percentage %, balan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com