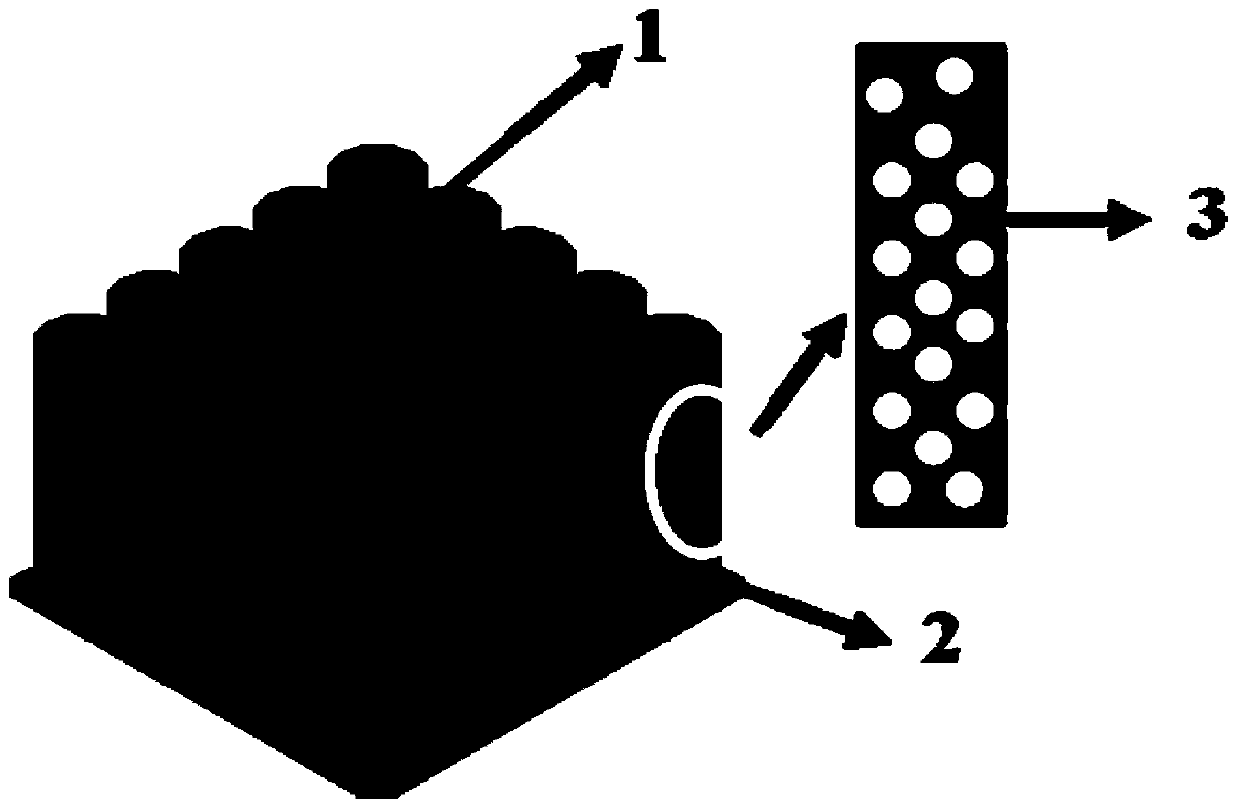

A nanoporous lithium titanate nitride nanowire/nanomembrane integrated material and its preparation method and application

A lithium titanate nitride, nanoporous technology, applied in nanotechnology, nanotechnology, hybrid/electric double-layer capacitor manufacturing, etc. Low, improved electrical conductivity, the effect of improving electron transport and ion transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

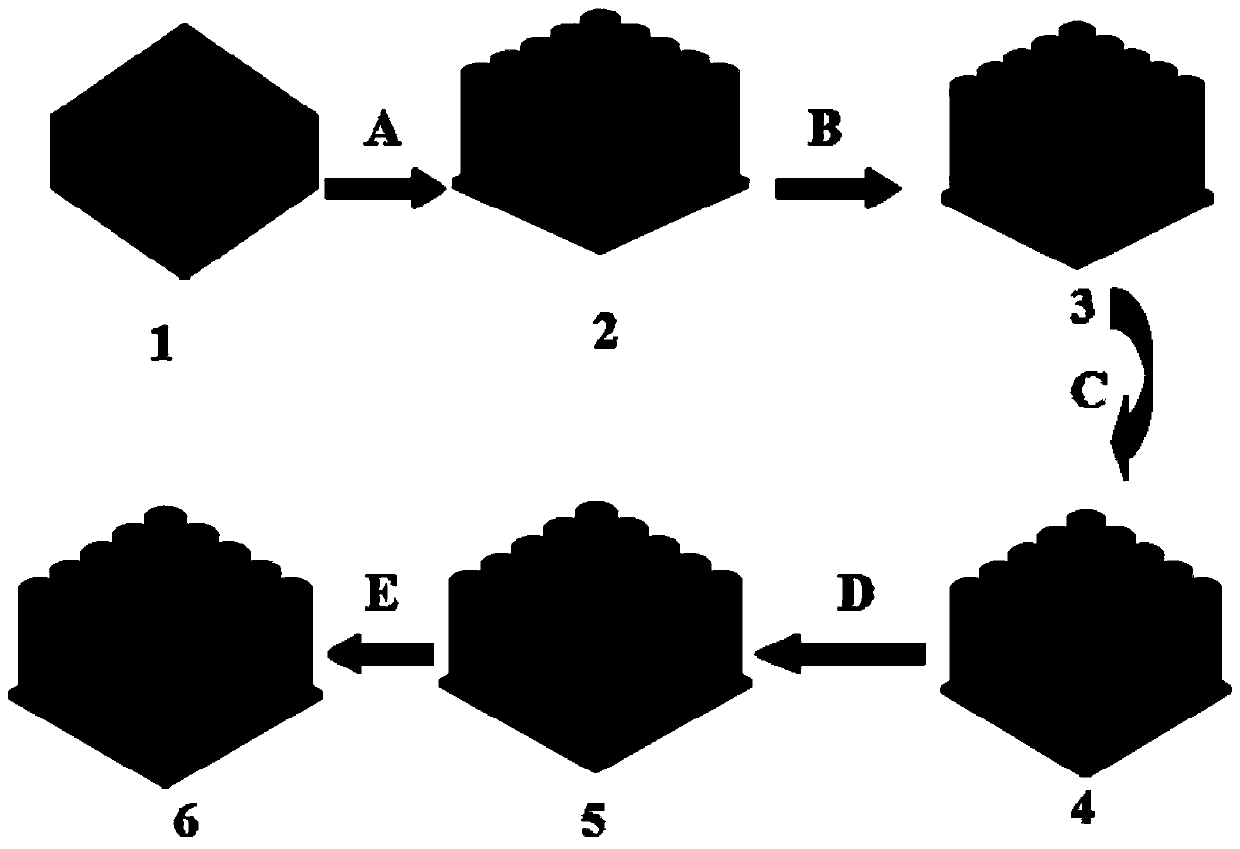

[0035] Preparation method: (for the process flow chart, see the appended figure 2 )

[0036] (1) Preparation of sodium titanate nanowire / nanofilm material by hydrothermal reaction method: put the metal titanium sheet into a sodium hydroxide solution of a certain concentration, perform hydrothermal reaction at a certain temperature, and first form a lithium titanate nanofilm, A lithium titanate nanowire array is then formed to prepare a sodium titanate nanowire / nano film material grown in situ on the titanium sheet.

[0037] (2) Preparation of amorphous phase lithium titanate nanowire / nanofilm material by ion exchange method: put sodium titanate nanowire / nanofilm material into a certain concentration of hydrochloric acid solution, and perform hydrogen ion exchange reaction for sodium ion at a certain temperature , to prepare titanate nanowire / nano-membrane material; then put titanate nano-wire / nano-membrane material into lithium hydroxide solution with a certain concentration...

Embodiment 2

[0049] Preparation method: (for the process flow chart, see the appended figure 2 )

[0050] (1) Preparation of sodium titanate nanowire / nanofilm material by hydrothermal reaction method: put the metal titanium sheet into a sodium hydroxide solution of a certain concentration, perform hydrothermal reaction at a certain temperature, and first form a lithium titanate nanofilm, A lithium titanate nanowire array is then formed to prepare a sodium titanate nanowire / nano film material grown in situ on the titanium sheet.

[0051] (2) Preparation of amorphous phase lithium titanate nanowire / nanofilm material by ion exchange method: put sodium titanate nanowire / nanofilm material into a certain concentration of hydrochloric acid solution, and perform hydrogen ion exchange reaction for sodium ion at a certain temperature , to prepare titanate nanowire / nano-membrane material; then put titanate nano-wire / nano-membrane material into lithium hydroxide solution with a certain concentration...

Embodiment 3

[0063] Preparation method: (for the process flow chart, see the appended figure 2 )

[0064] (1) Preparation of sodium titanate nanowire / nanofilm material by hydrothermal reaction method: put the metal titanium sheet into a sodium hydroxide solution of a certain concentration, perform hydrothermal reaction at a certain temperature, and first form a lithium titanate nanofilm, A lithium titanate nanowire array is then formed to prepare a sodium titanate nanowire / nano film material grown in situ on the titanium sheet.

[0065] (2) Preparation of amorphous phase lithium titanate nanowire / nanofilm material by ion exchange method: put sodium titanate nanowire / nanofilm material into a certain concentration of hydrochloric acid solution, and perform hydrogen ion exchange reaction for sodium ion at a certain temperature , to prepare titanate nanowire / nano-membrane material; then put titanate nano-wire / nano-membrane material into lithium hydroxide solution with a certain concentration...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com