A battery anode reforming layer material, preparation method and power generation method for a solid oxide fuel cell

A technology of solid oxide and fuel cell, which is applied in the field of battery anode reforming layer material, preparation, and power generation of solid oxide fuel cell. Problems such as sintering and growth, to achieve the effect of enriching the reaction interface, high electrochemical catalytic activity, and strong redox activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

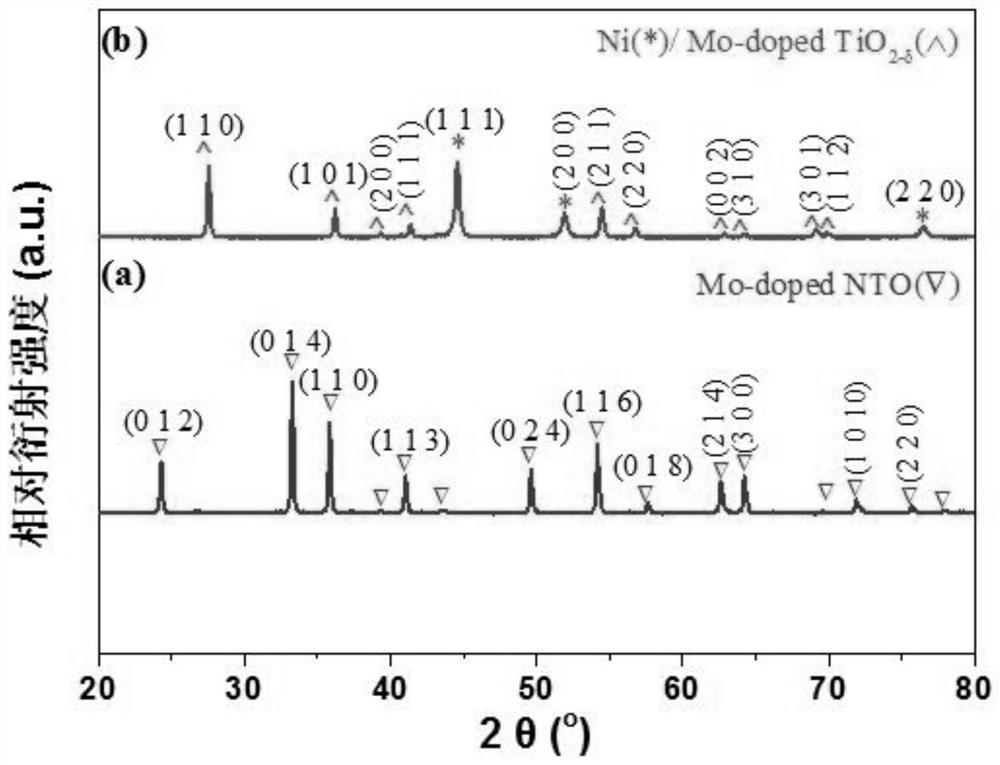

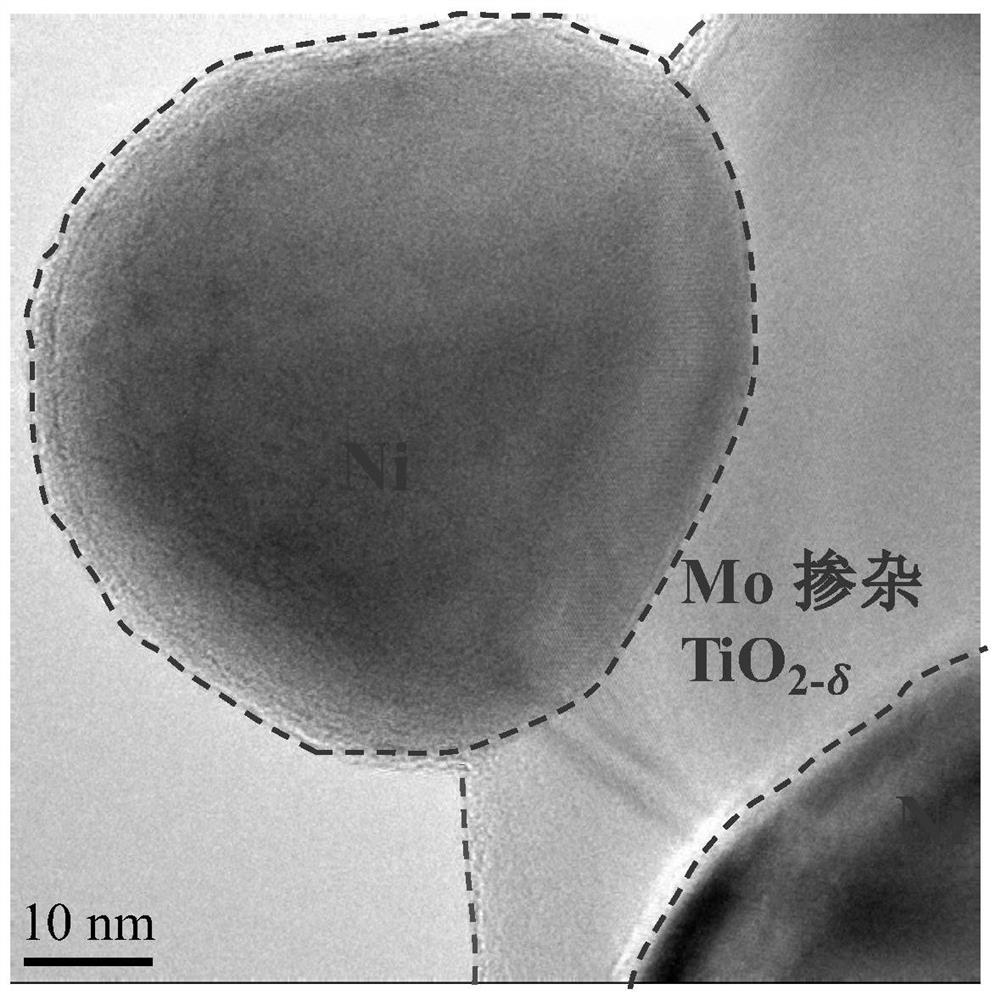

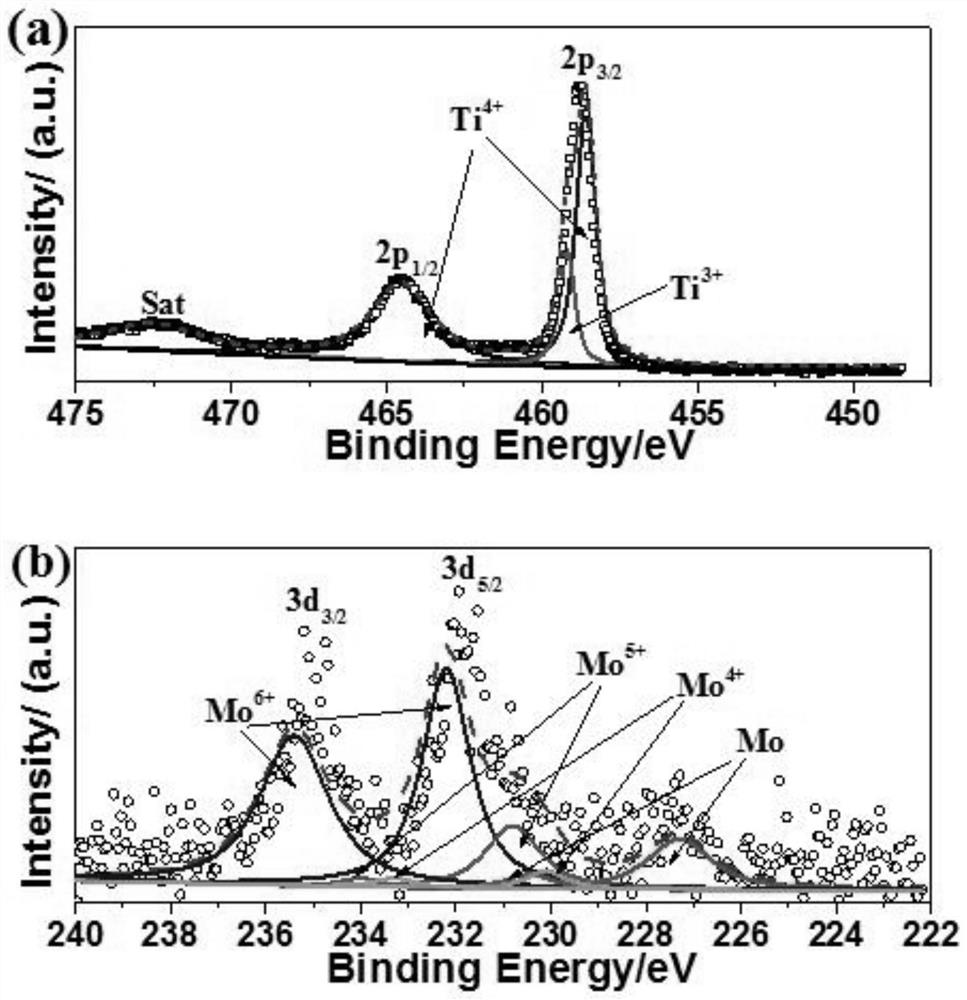

[0032] A battery anode reforming layer material, chemical formula is Ni 2 Mo 0.05 Ti 1.925 o 6-2δ , where x is Mo 6+ doped Ti 4+ bit molar ratio. The preparation method of the anode reforming layer material of the battery comprises the following steps: adding nickel nitrate, ammonium molybdate, and n-butyl titanate to water in sequence at a molar ratio of 1:0.025:0.9625, and then adding complexing agent ethylenediamine Tetraacetic acid and citric acid, the molar ratio between metal ions, citric acid and ethylenediaminetetraacetic acid in the solution is 1:1:0.8, stir until the complexing agent dissolves, then add ammonia water to adjust the pH value of the solution to 6-7; Pour the solution into a crucible and heat it. After the solution is concentrated and evaporated to dryness, spontaneous combustion occurs. The powder obtained after combustion is calcined in an air atmosphere at 600-1000°C for 3-5 hours to obtain Ni 2 Mo 0.05 Ti 1.925 o 6-2δ Reforming layer of powd...

Embodiment 2

[0047] A battery anode reforming layer material, chemical formula is Ni 2 Mo 0.1 Ti 1.85 o 6-2δ , where x is Mo 6+ doped Ti 4+ bit molar ratio. The preparation method of the anode reforming layer material of the battery comprises the following steps: adding nickel nitrate, ammonium molybdate, and n-butyl titanate to water in a molar ratio of 1:0.05:0.925 in sequence, and then adding the complexing agent ethylenediamine Tetraacetic acid and citric acid, the molar ratio between metal ions, citric acid and ethylenediaminetetraacetic acid in the solution is 1:1:0.8, stir until the complexing agent dissolves, then add ammonia water to adjust the pH value of the solution to 6-7; Pour the solution into a crucible and heat it. After the solution is concentrated and evaporated to dryness, spontaneous combustion occurs. The powder obtained after combustion is calcined in an air atmosphere at 600-1000°C for 3-5 hours to obtain Ni 2 Mo 0.1 Ti 1.85 o 6-2δ Reforming layer of powder...

Embodiment 3

[0051] A battery anode reforming layer material, chemical formula is Ni 2 Mo 0.002 Ti 1.997 o 6-2δ , where x is Mo 6+ doped Ti 4+ bit molar ratio. The preparation method of the anode reforming layer material of the battery comprises the following steps: adding nickel nitrate, ammonium molybdate, and n-butyl titanate to water in a molar ratio of 1:0.001:0.9985 in sequence, and then adding complexing agent ethylenediamine Tetraacetic acid and citric acid, the molar ratio between metal ions, citric acid and ethylenediaminetetraacetic acid in the solution is 1:1:0.8, stir until the complexing agent dissolves, then add ammonia water to adjust the pH value of the solution to 6-7; Pour the solution into a crucible and heat it. After the solution is concentrated and evaporated to dryness, spontaneous combustion occurs. The powder obtained after combustion is calcined in an air atmosphere at 600-1000°C for 3-5 hours to obtain Ni 2 Mo 0.1 Ti 1.85 o 6-2δ Reforming layer of powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com