Variable-angle flip bucket and shutter type stilling pool tail bucket combined energy dissipation structure and using method thereof

A louver-type and stilling pool technology, which is applied in water conservancy projects, marine engineering, coastline protection, etc., can solve problems such as cavitation and erosion on the dam surface, and achieve improved cavitation resistance, energy dissipation efficiency, and energy dissipation rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

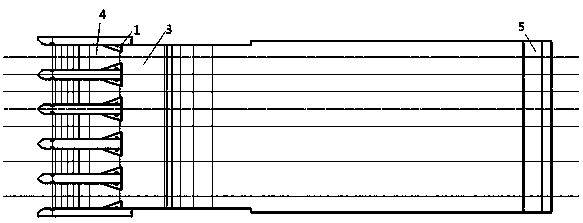

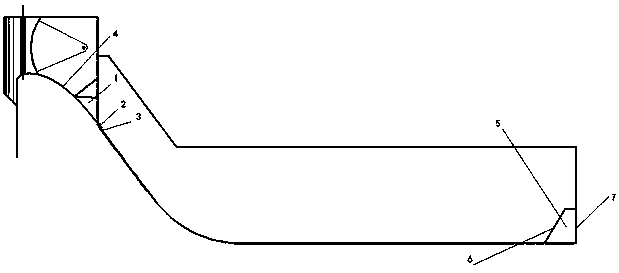

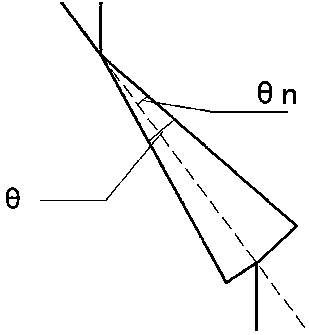

[0033] In the variable-angle ridge part of this example, the end of the wide-tailed pier 1 is connected to the head of the variable-angle ridge 2, and the tail of the variable-angle ridge 2 is connected to the first step of the stepped overflow dam 3, and the water flows through the end of the wide-tailed pier 1. The flow direction changes angle to pick up the ridge 2, and then flows to the stepped overflow dam 3 through the pick up ridge, when the single-width flow rate at the top of the weir is 235m 3 / s·m—270 m 3 When within the / s m range, by adjusting the angle of the hurdle θ 1 12° to change the shape of the water flow through the weir, so that the water flow ejected from the end of the wide-tailed pier 1 can be adjusted by adjusting the angle of the ridge 2 θ 1 To make the injected water fully contact with the air, and create aeration conditions at the bottom of the water tongue, increase the aeration cavity and aeration concentration, and provide the energy dissipat...

Embodiment 2

[0037] In the variable-angle ridge part of this example, the end of the wide-tailed pier 1 is connected to the head of the variable-angle ridge 2, and the tail of the variable-angle ridge 2 is connected to the first step of the stepped overflow dam 3, and the water flows through the end of the wide-tailed pier 1. The flow direction is changed to pick up the ridge 2, and then flow to the stepped overflow dam 3 through the pick up dam. When the single width flow at the weir top is 190m 3 / s·m—235 m 3 / s m range, by adjusting the angle of the hurdle θ 2 8° to change the shape of the water flow through the weir, so that the water flow ejected from the end of the wide-tailed pier 1 can be adjusted by adjusting the angle of the ridge 2 θ 2 To make the injected water fully contact with the air, and create aeration conditions at the bottom of the water tongue, increase the aeration cavity and aeration concentration, and provide the energy dissipation rate of the stepped overflow da...

Embodiment 3

[0041] In the variable-angle ridge part of this example, the end of the wide-tailed pier 1 is connected to the head of the variable-angle ridge 2, and the tail of the variable-angle ridge 2 is connected to the first step of the stepped overflow dam 3, and the water flows through the end of the wide-tailed pier 1. The flow direction is changed to pick the ridge 2, and then flow to the stepped overflow dam 3 through the pick ridge, when the single-width flow of the weir crest does not exceed 190m 3 / s·m, by adjusting the angle of the hurdle θ 3 3° to change the shape of the water flow over the weir, so that the water flow ejected from the end of the wide-tailed pier 1 can be adjusted by adjusting the angle of the ridge 2 θ 3 To make the injected water fully contact with the air, and create aeration conditions at the bottom of the water tongue, increase the aeration cavity and aeration concentration, and provide the energy dissipation rate of the stepped overflow dam;

[0042]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com