Pretreatment system of SCR (selective catalytic reduction) catalyst device

A technology of SCR catalyst and front plate, which is applied in the field of exhaust gas treatment devices, can solve the problems of lack of rectification design, poor effect of SCR reduction reaction, etc., and achieve the effect of saving assembly space, improving effect and improving treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

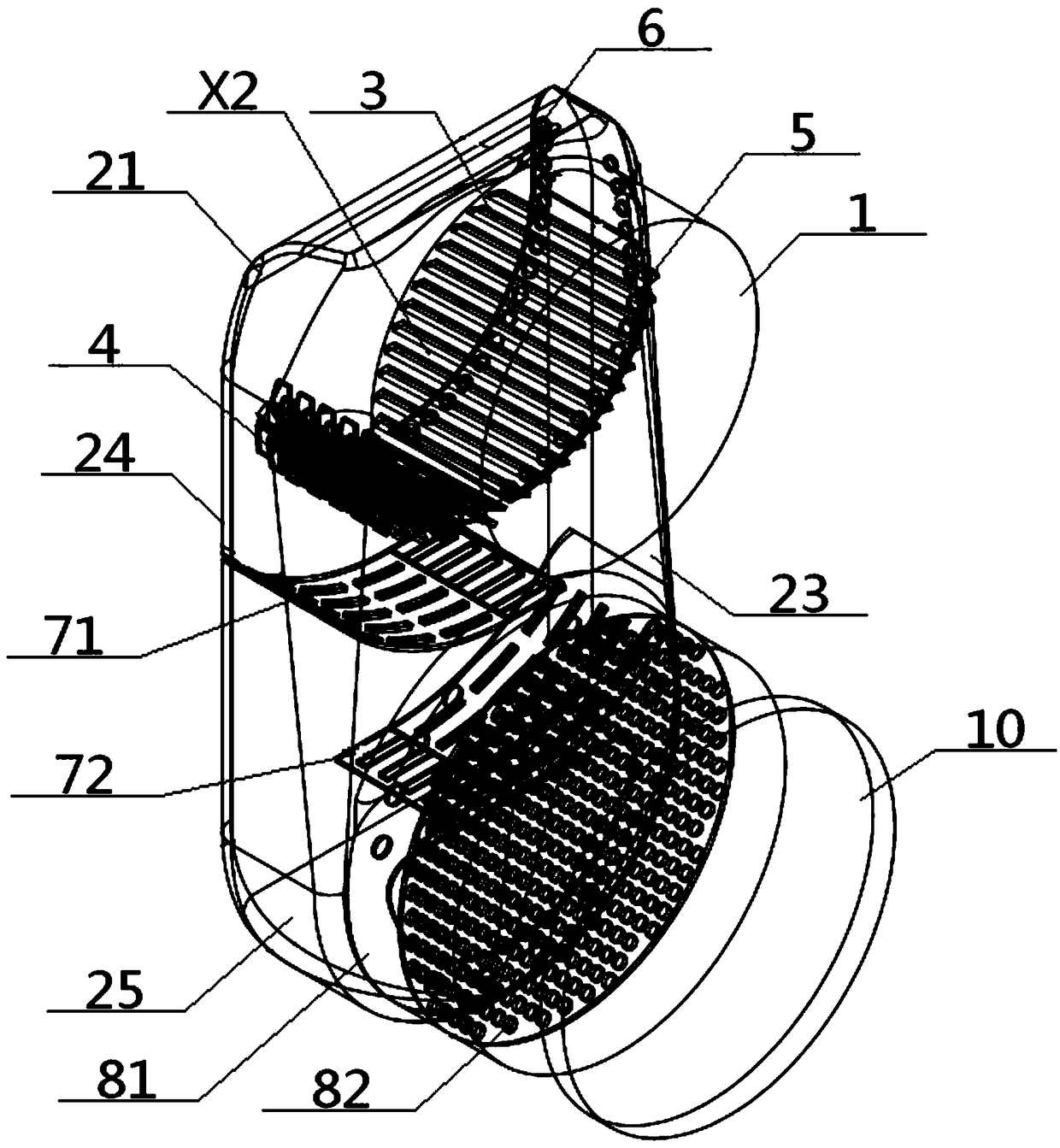

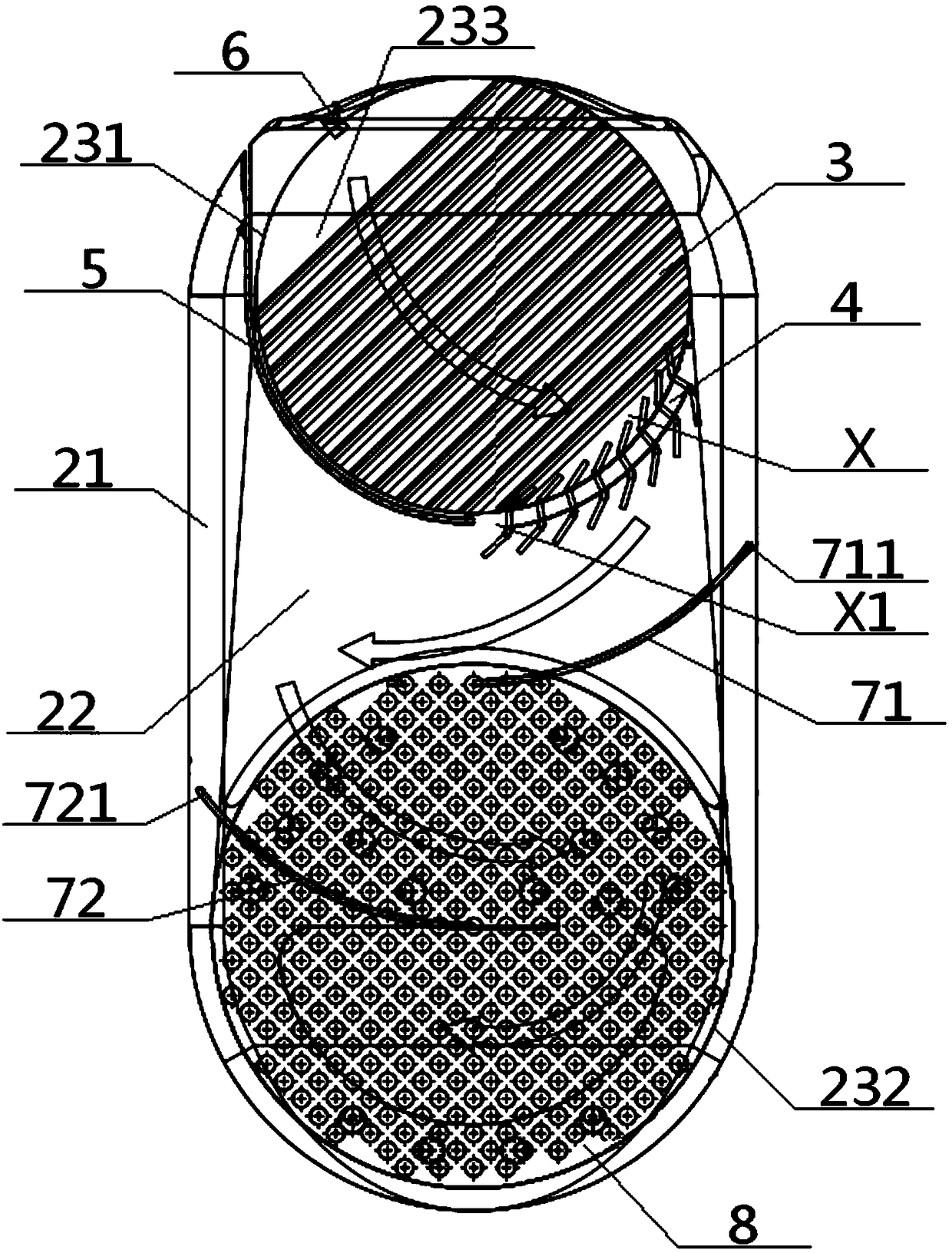

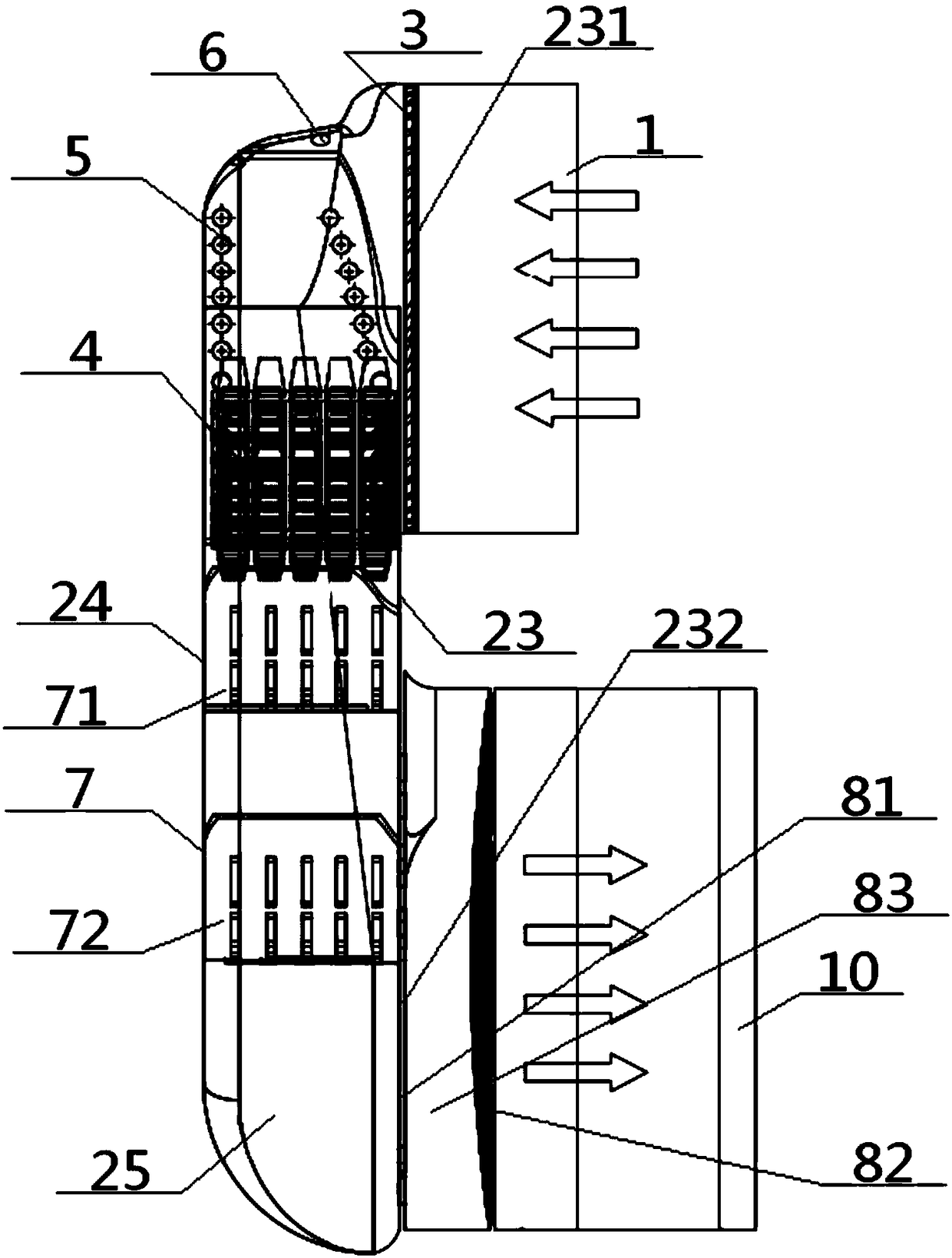

[0054] see Figure 1 to Figure 9 , a pretreatment system of an SCR catalyst device, comprising a DPF input end 1, an SCR output end 10 and a transition part 2, one end of the transition part 2 communicates with the DPF particle trapping device through the DPF input end 1, and the transition part 2 The other end communicates with the SCR catalyst device through the SCR output port 10; the transition part 2 includes a transition housing 21 and a transition cavity 22 provided inside, and the transition housing 21 includes a transition front plate 23, a transition rear plate 24 and a transition between two There is a ring-shaped transitional side wall 25 between them, the top of the transitional front plate 23 is provided with a front panel inlet 231 communicating with the DPF input end 1, and the bottom of the transitional front panel 23 is provided with a front panel inlet 231 communicated with the SCR output end 10. The plate outlet 232, and the DPF input end 1, the transition ...

Embodiment 2

[0056] Basic content is the same as embodiment 1, the difference is:

[0057] The vertical rectification unit 7 includes an arc-shaped upper orifice plate 71 and an arc-shaped lower orifice plate 72 arranged up and down. The arc-shaped upper orifice plate 71 includes an arc-shaped upper connection end 711, an arc-shaped middle hole portion 712, and an arc-shaped upper orifice plate 71 connected in sequence. The upper hanging end 713, the upper arc hole portion 712 is provided with a plurality of arc air vents 714, and the arc-shaped lower orifice plate 72 includes the arc lower connecting end 721, the arc lower middle hole portion 722 and the arc lower hole. The overhanging end 723 and the under-arc middle hole 722 are provided with a plurality of under-arc ventilation holes 724; the above-arc connecting end 711 is connected to the transition side wall 25, and the above-arc middle hole 712 and the over-arc hanging end 713 are all located at Right below the ammonia gas generati...

Embodiment 3

[0059] Basic content is the same as embodiment 1, the difference is:

[0060] The horizontal rectification unit 8 includes a rectification inner orifice plate 81 and a rectification outer orifice plate 82 arranged coaxially. Inside the SCR output end 10, the part of the SCR output end 10 sandwiched between the rectification inner orifice plate 81 and the rectification outer orifice plate 82 is a rectification orifice cavity 83, and the rectification inner orifice plate 81 is provided with a plurality of rectification inner orifice plates. Holes 84, the rectification outer orifice plate 82 is provided with a plurality of rectification outer holes 85.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com