Front edge design method for optimizing suction surface wave system and suppressing fan shock wave noise

A design method and optimized design technology, applied in mechanical equipment, components of pumping devices for elastic fluids, non-variable-capacity pumps, etc., can solve the problems of limited shock noise effect and difficult to improve greatly. , to achieve the effect of significant benefits, reduced shock noise intensity, and strong engineering application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

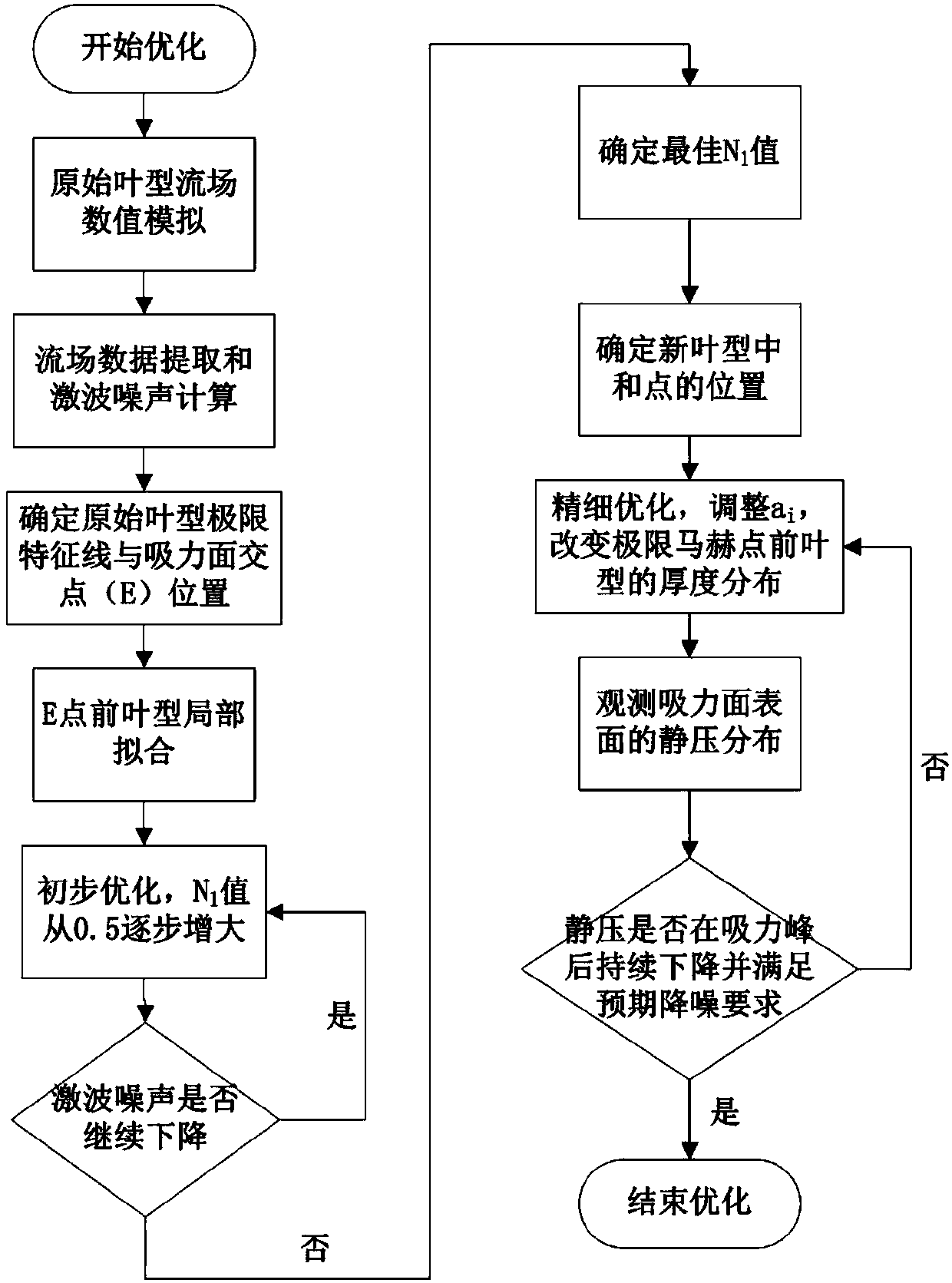

Method used

Image

Examples

Embodiment 1

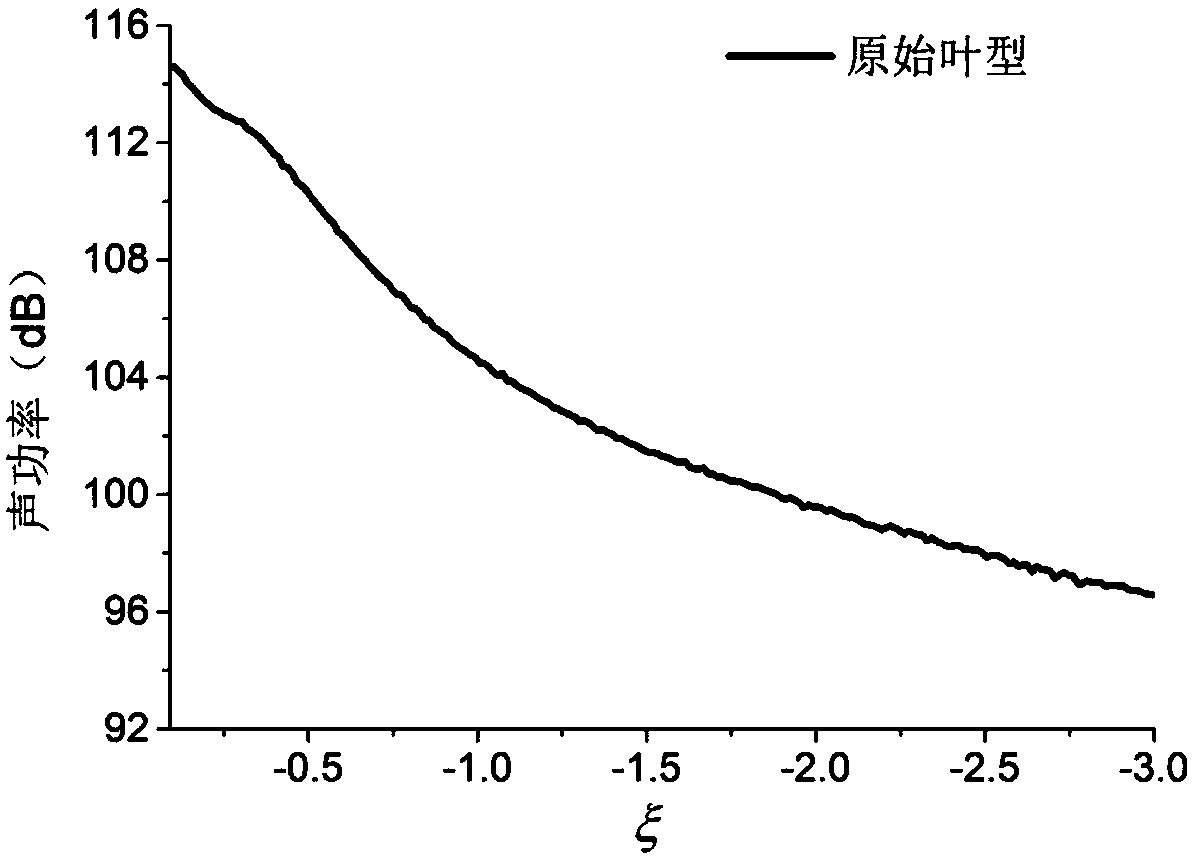

[0044] Taking the published CM-1.2 airfoil as an example, the design Mach number of this airfoil is 1.2, and the geometric coordinates can be found in the literature "Qiu Ming. Research on Shock Wave Structure in the Rotor Channel of Axial Compressor with High Pressure Ratio [D]. Nanjing Aviation Aerospace University, 2014."

[0045] Carry out numerical simulation on the original airfoil according to the method described in step 1). Compared with the traditional unsteady CFD-CAA (computational fluid dynamics-computational aeroacoustics) hybrid method for calculating noise, the RANS method adopted in the present invention can shorten the calculation time by two orders of magnitude, and adopts high-precision calculation format and fine grid To meet the accuracy of shock wave capture and reduce numerical dissipation; the stretched grid absorbing layer and non-reflective boundary conditions are used to avoid the pollution of numerical reflection waves at the entrance to the comput...

Embodiment 2

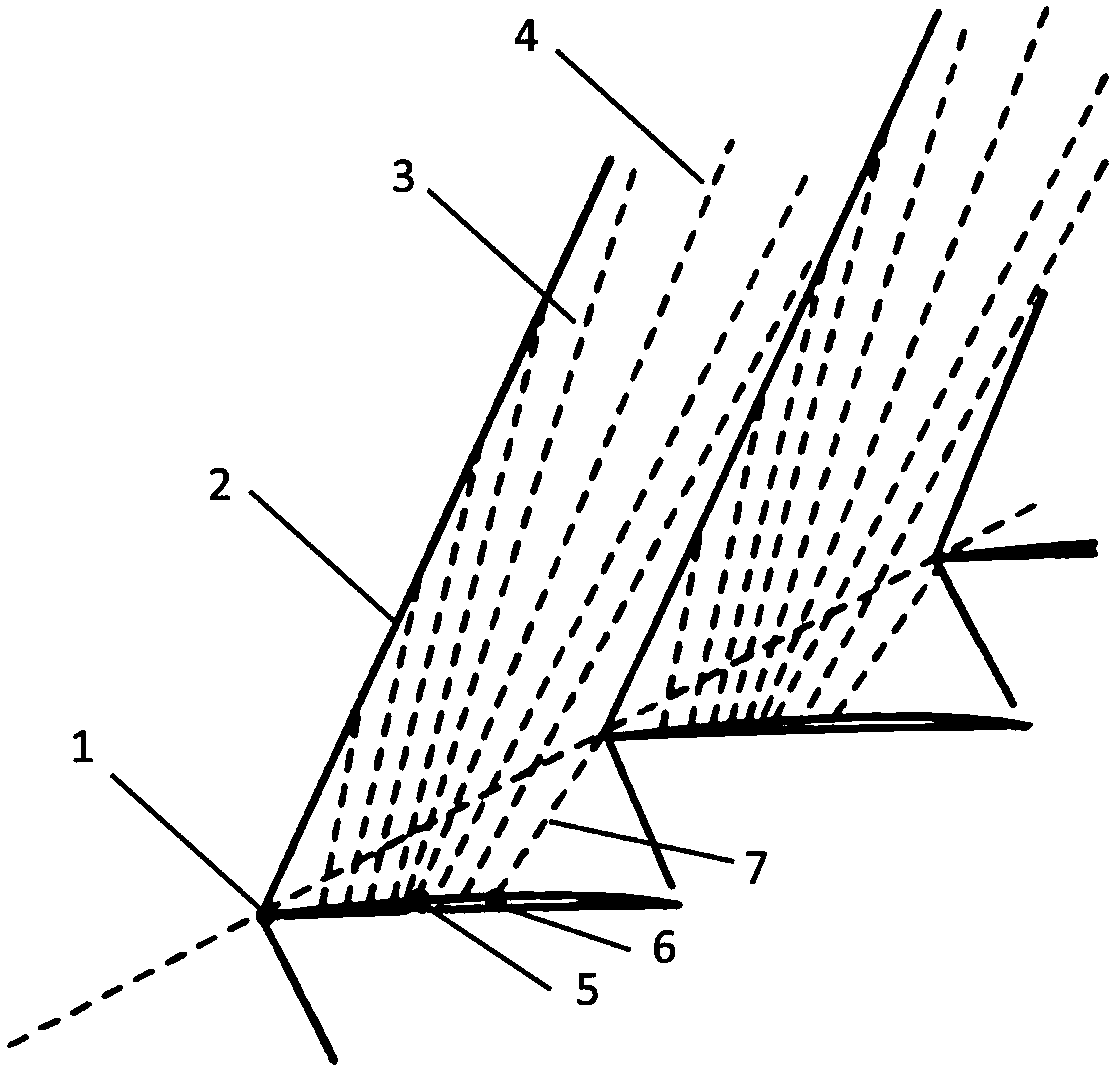

[0056] In order to verify the three-dimensional fan / rotor blade design method and the three-dimensional fan / rotor blade design method based on the optimal design of the leading edge of the primitive blade profile proposed by the present invention and the optimal design of the leading edge of the primitive blade profile combined with the curved shape, the NASARotor37 rotor ( R37) as an example, the rotor above 1 / 3 of the blade height is in the ultrasonic working condition. For specific parameters, please refer to the literature "Dunham J. CFD validation for propulsion system components (la validation CFD des organs des propulseurs) [R]. AND DEVELOPMENT NEUILLY-SUR-SEINE (FRANCE), 1998.”

[0057] The implementation steps of the leaf shape optimization process are consistent with the CM-1.2 leaf shape in Embodiment 1, and only a brief description and specific parameters are given here:

[0058] Taking the R37 rotor (Rotor_2) as an example, the three-dimensional fan / rotor blade de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com