Microwave concentration online measurement system

A measurement system and concentration technology, which is applied in the field of microwave concentration online measurement system, can solve the problems of inability to detect and deal with abnormal conditions such as pipe blockage in time, high cost and low practicability, etc., to ensure accuracy and effectiveness, The effect of strong environmental adaptability and increased accuracy of detection data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

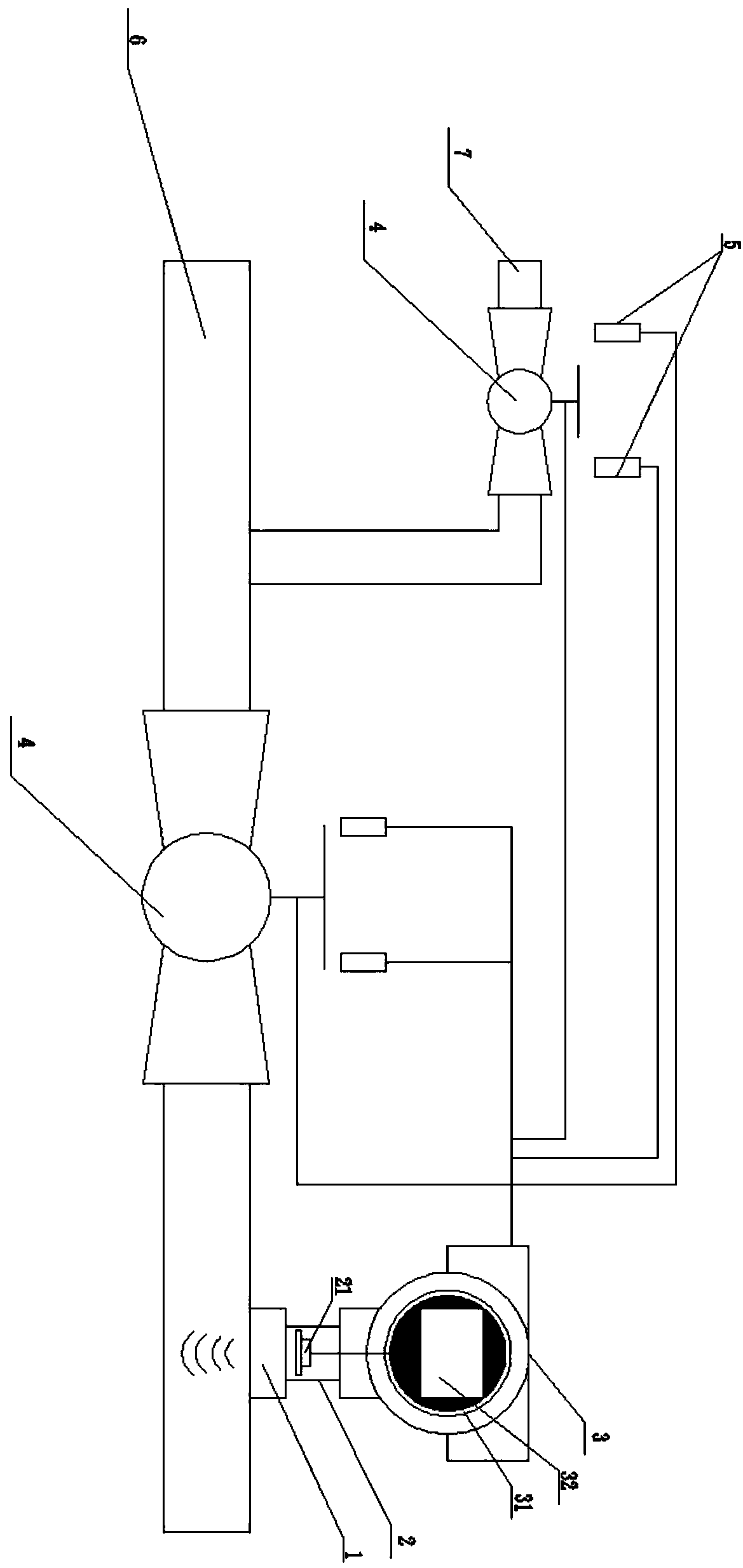

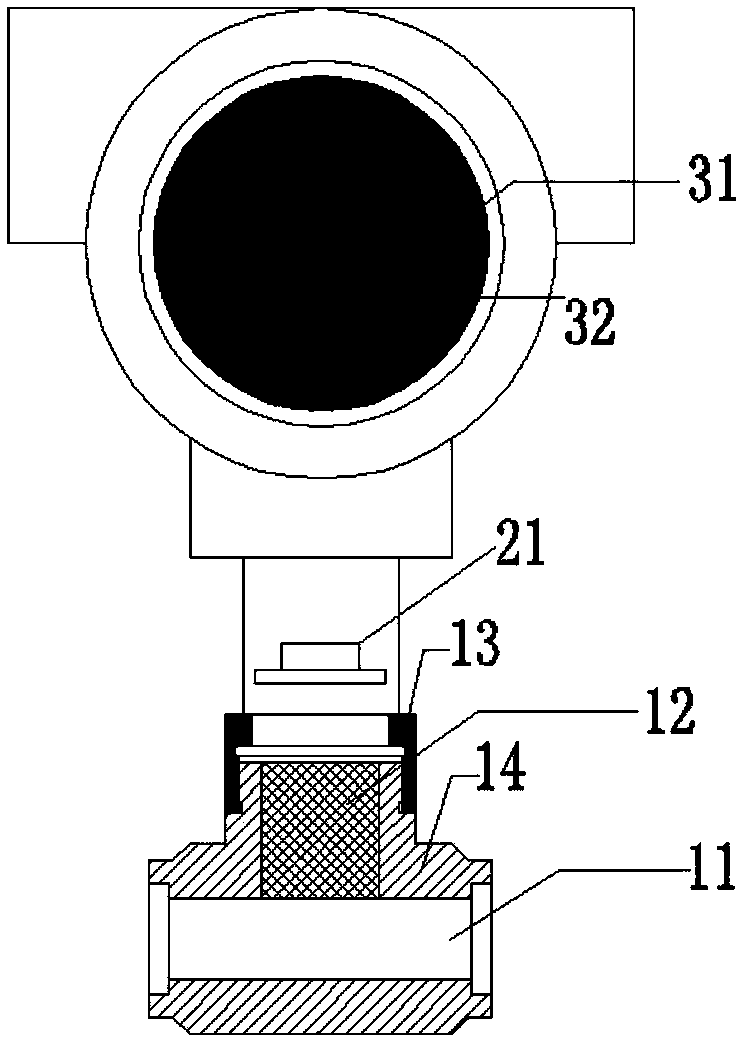

[0018] Hereinafter, referring to the drawings, the microwave concentration online measurement system of the present invention will be described in detail.

[0019] Such as Figure 1 to 2 As shown, the microwave concentration online measurement system includes a mounting kit 1, a sensor kit 2, a meter head 3, an electric valve 4, and a proximity switch 5. The mounting kit 1 includes a base 11 and a base seal 12, and the base 11 is installed on the On the powder measuring tube 6, connect the powder measuring tube 6 left and right. The installation kit 1 realizes the functions of sealing, wear resistance and pressure resistance; the test cutoff is isolated from other parts to facilitate the online replacement and maintenance of the equipment. A base seal 12 is installed at the upper end of the base 11, and a sealing rubber ring 13 is used to tightly fix the installation place.

[0020] A microwave radar 21 is installed inside the sensor suite 2, and the microwave radar 21 is package...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com